17 18

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I NOZZLE REPLACEMENT

NOZZLE REPLACEMENT I TABLE OF CONTENTS

To remove the long-range primary nozzle, rst note the nozzle’s orientation prior to removal.

The G90’s primary nozzle has a protruding rail that must engage the slot on the right side of the

nozzle opening. Understanding this will help during the installation process later. Using needle-

nose pliers, grab the nozzle’s outer ring next to the recess on the right side of the nozzle opening

and then pull outward. If necessary, grab the nozzle’s orice to gain a better grip. Discard the old

nozzle as the removal process can damage the nozzle and negatively aect the performance.

Insert the replacement nozzle into the nozzle housing. Press rmly until the nozzle stops. Turn

the nozzle-retaining setscrew clockwise while making sure that the setscrew does not distort

the nozzle. Lower the setscrew in front of the nozzle only as far as necessary to prevent nozzle

movement. Take care not to position the setscrew in front of or against the nozzle’s orice as

performance can be negatively aected.

If the nozzle size or color has been changed, please note that the adjustable stator will likely need

to be reset. Refer to the Stator Adjustment section in this manual for information on how to reset

the stator.

The G90’s short-range and mid-range nozzles are performance matched to all G90 long-range

nozzles. As a result, replacement of these nozzles is normally required only when a nozzle has

been damaged. If replacement does become necessary, it is important to note that these nozzles

must be installed in the correct orientation for optimal performance.

Prior to removal of the G90’s short-range or mid-range nozzle, note the dierences between the

nozzle on the le and right.

G90 Full Circle: The short-range nozzle is black and on the le side date codes 0511 &

prior (FIGURE 39).

The short-range nozzle is red and on the le dates codes

0611 and aer. (FIGURE 39).

The mid-range nozzle is blue and on the right side (FIGURE 39).

Using needle-nose pliers, grab the nozzle’s orice then pull outward. Discard the old nozzle

as the removal process will damage the nozzle and negatively aect the performance. Insert

the replacement nozzle into the nozzle housing and press rmly until it stops. Turn the nozzle-

retaining setscrew clockwise to a position in front of the nozzle that prevents nozzle movement.

Take care not to position the setscrew in front of or against the nozzle’s orice as its performance

can be negatively aected.

NOZZLE REPLACEMENT G95 RISERS

To view and replace the nozzles, it is necessary to compress the riser spring by grabbing the riser

seal assembly (FIGURE 37), pressing downward and then holding riser rmly to prevent the spring

from moving upwards.

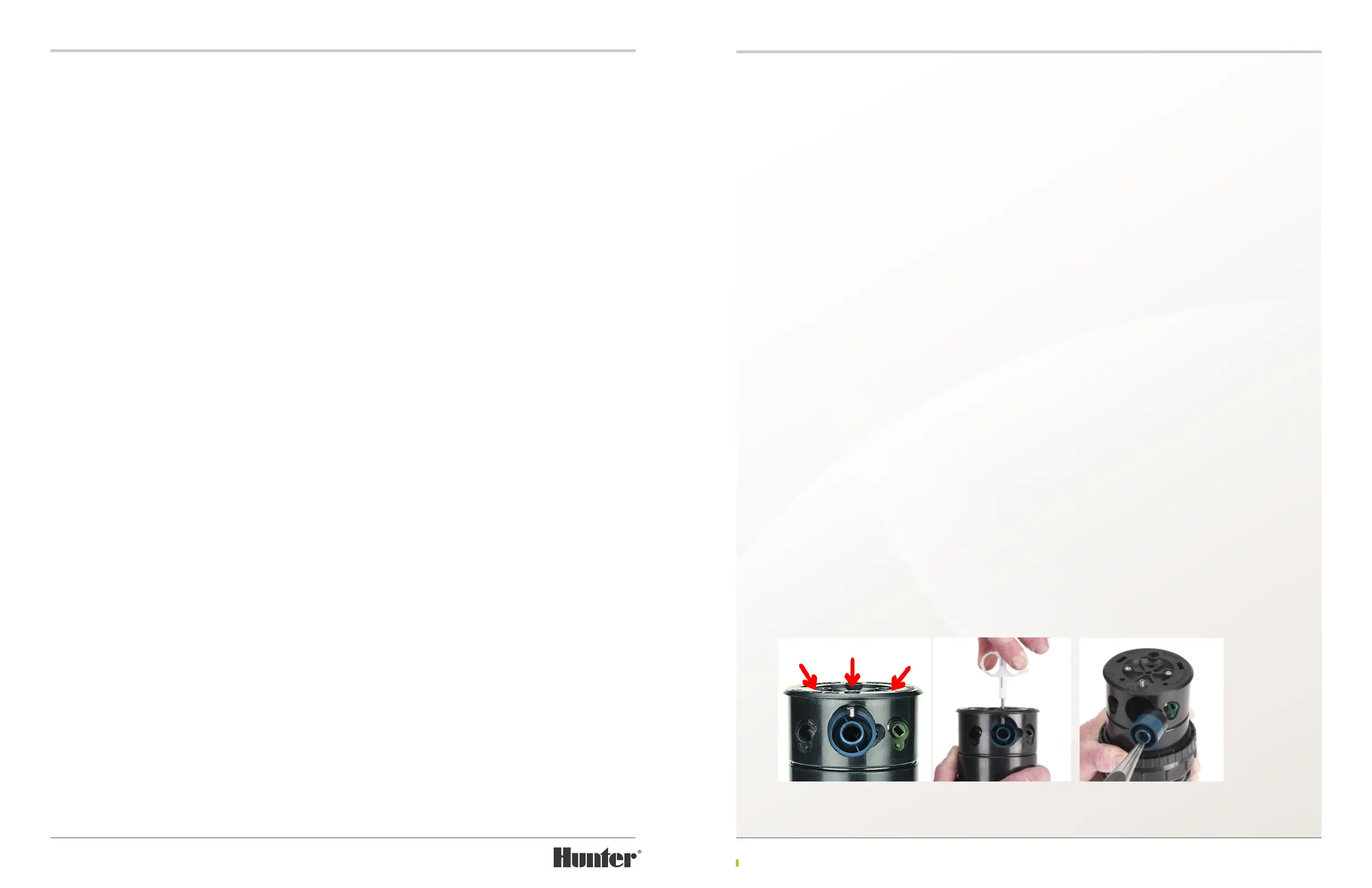

The G95 riser has three color-coded nozzles

that all face the same direction. All G95 nozzles

are retained in the nozzle housing (turret) with

three setscrews (FIGURE 40). Each setscrew

has a

3

/

32

inch Allen recess at the top. Insert

the metal end of the Hunter wrench or a

3

/

32

inch wrench into setscrew that is above the

nozzle to be replaced. Engage the setscrew and

turn counter-clockwise until the bottom of the

setscrew clears the top of the nozzle (FIGURE 41).

To remove the long-range primary nozzle, rst

note the nozzle’s orientation prior to removal.

The G95’s primary nozzle has a protruding rail

that must engage the slot on the right side of

the nozzle opening. Understanding this will

help during the installation process later.

Using needle-nose pliers, grab the nozzle’s

outer ring next to the recess on the right side

of the nozzle opening and then pull outward

(FIGURE 42). If necessary, grab the nozzle’s

orice to gain a better grip. Discard the old

nozzle as the removal process can damage the

nozzle and negatively aect its performance.

Insert the replacement nozzle into the nozzle

housing. Press rmly until the nozzle stops.

Turn the nozzle-retaining setscrew clockwise

while making sure that the setscrew does not

distort the nozzle. Lower the setscrew in front

of the nozzle only as far as necessary to prevent

nozzle movement. Take care not to position the

setscrew in front of or against the nozzle’s orice

as its performance can be negatively aected.

If the nozzle size or color has been changed,

please note that the adjustable stator will likely

need to be reset. Refer to the Stator Adjustment

section in this manual for information on how to

reset the stator.

The G95’s short-range and mid-range nozzles

are performance matched to all G95 long-range

nozzles. As a result, replacement of these nozzles

is normally required only when a nozzle has

been damaged. If replacement does become

necessary, it is important to note that these

nozzles must be installed in the correct

orientation for optimal performance.

Prior to removal of the G95’s short-range or

mid-range nozzle, note the dierences between

the nozzle on the le and right.

G95 Adj. Arc: The short-range nozzle is black and on the le side date codes 0511 and

prior (FIGURE 40).

The short-range nozzle is red and on the le side date codes 0611 and aer

The mid-range nozzle is green and on the right side (FIGURE 40).

FIGURE 40 FIGURE 41 FIGURE 42

Loading...

Loading...