19 20

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I RISER SEAL REPLACEMENT

RISER SEAL REPLACEMENT I TABLE OF CONTENTS

Using needle-nose pliers, grab the nozzle’s orice then pull outward. Discard the old nozzle as

the removal process will damage the nozzle and negatively aect the performance. Insert the

replacement nozzle into the nozzle housing and press rmly until it stops. Turn the nozzle-

retaining setscrew clockwise to a position in front of the nozzle that prevents nozzle movement.

Take care not to position the setscrew in front of or against the nozzle’s orice as its performance

can be negatively aected.

RISER SEAL REPLACEMENT G35, G70 & G75 RISERS

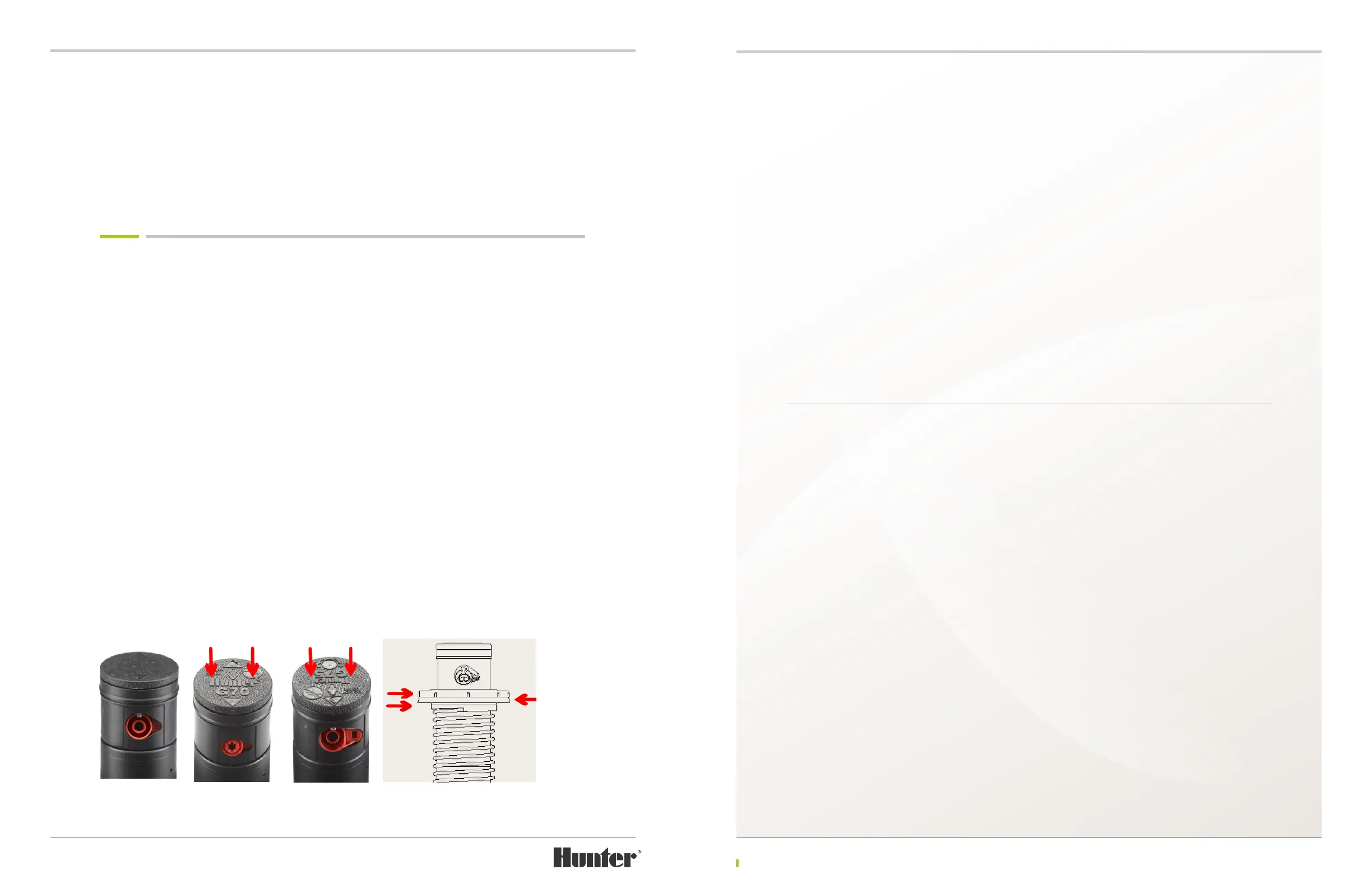

The G35, G70 and G75 riser seal assemblies and the compressed retraction spring are retained

on the risers with the rubberized logo cap assembly. It is necessary to remove the rubberized

logo cap assembly in order to replace the riser seal assembly. To remove the rubberized logo cap

assembly, it is necessary to fully compress the riser spring by grabbing the riser seal assembly

(FIGURE 43), pressing downward and then holding riser rmly to prevent the spring from moving

upwards.

Caution! The riser assembly is under spring tension. Eye protection should be worn and safe-

handling procedures followed when servicing this product.

Hold the riser seal assembly down with one hand. Using the other hand, locate the two hidden

screws that retain the rubberized logo cap assembly. These can be found by pressing down on the

rubberized logo cap close to the “H” and the “r” on the Hunter logo (FIGURE 44 & 45). The Phillips

headed retaining screws are directly beneath these depressions. Insert the Phillips screwdriver

through the rubberized membrane and engage each retaining screw. Turn counter-clockwise to

remove each screw.

Prior to removing the rubberized logo cap assembly, note its orientation as it relates to the

nozzles below. This will help with the assembly process later. Remove the rubberized logo cap and

set aside.

While still holding the compressed riser seal

assembly and retraction spring with one hand,

use the other hand to grasp the bottom of the

riser assembly. Slowly release the compression

of the retraction spring until it is fully extended

and no pressure is felt.

Prior to removing the riser seal assembly, note

the orientation and sequence of the three

individual seal assembly parts (FIGURE 46).

The Upper Seal Support is on top and its lower

surface nests perfectly with the top of the riser

seal. The Riser Seal is the rubberized part in the

middle. The Lower Seal Support (also known as

the Upper Spring Support) has an upper surface

that nests perfectly to the lower surface of the

Riser Seal. The Support’s lower surface also

provides a nest for the retraction spring. During

assembly, these three parts must keep this

sequence and orientation in order for the seal

assembly to function properly.

If any one of the three parts in the seal assembly

needs replacement, it is highly recommended

that all three components be replaced. To

reassemble the riser, place the seal assembly

on top of the retraction spring and then compress.

While rmly holding the retraction spring and

seal assembly down, place the logo cap assembly

on top of the riser in the correct orientation.

Insert the two stainless-steel screws through

the rubberized membranes on the logo cap and

hand tighten with a Phillips screwdriver.

RISER SEAL REPLACEMENT G80 RISERS

The G80 riser seal-block assembly and the

compressed retraction spring are retained on

the riser with the shroud/logo-cap assembly. It

is necessary to remove this assembly in order

to service the G80’s riser seal components. To

remove the shroud/logo-cap assembly, it is

necessary to fully compress the riser spring by

grabbing the riser seal-block assembly, pressing

downward and then holding riser rmly to

prevent the spring from moving upwards

(FIGURE 47).

Caution! The riser assembly is under spring tension. Eye protection should be worn and safe-

handling procedures followed when servicing this product.

Press the riser seal-block assembly down with

one hand and hold rmly. Locate the stainless-

steel retaining screw on top of the shroud/

logo-cap assembly (FIGURE 48). Use a Phillips

screwdriver to engage the screw and turn

counter-clockwise to remove. Prior to removal

of the shroud, take note that the large nozzle

arrow on top of the shroud’s rubberized logo

cap is orientated directly over the larger, long-

range nozzle. This will help with the shroud

installation process later.

While rmly holding the compressed spring and

seal-block assembly downward, grab and li the

shroud o the nozzle housing then set it aside

(FIGURE 49). Slowly li to release the spring

compression. Note the orientation of the seal-

block assembly for installation later (FIGURE

50). Next, remove the seal-block assembly and

retraction spring.

FIGURE 43 FIGURE 44 FIGURE 45 FIGURE 46

Loading...

Loading...