31

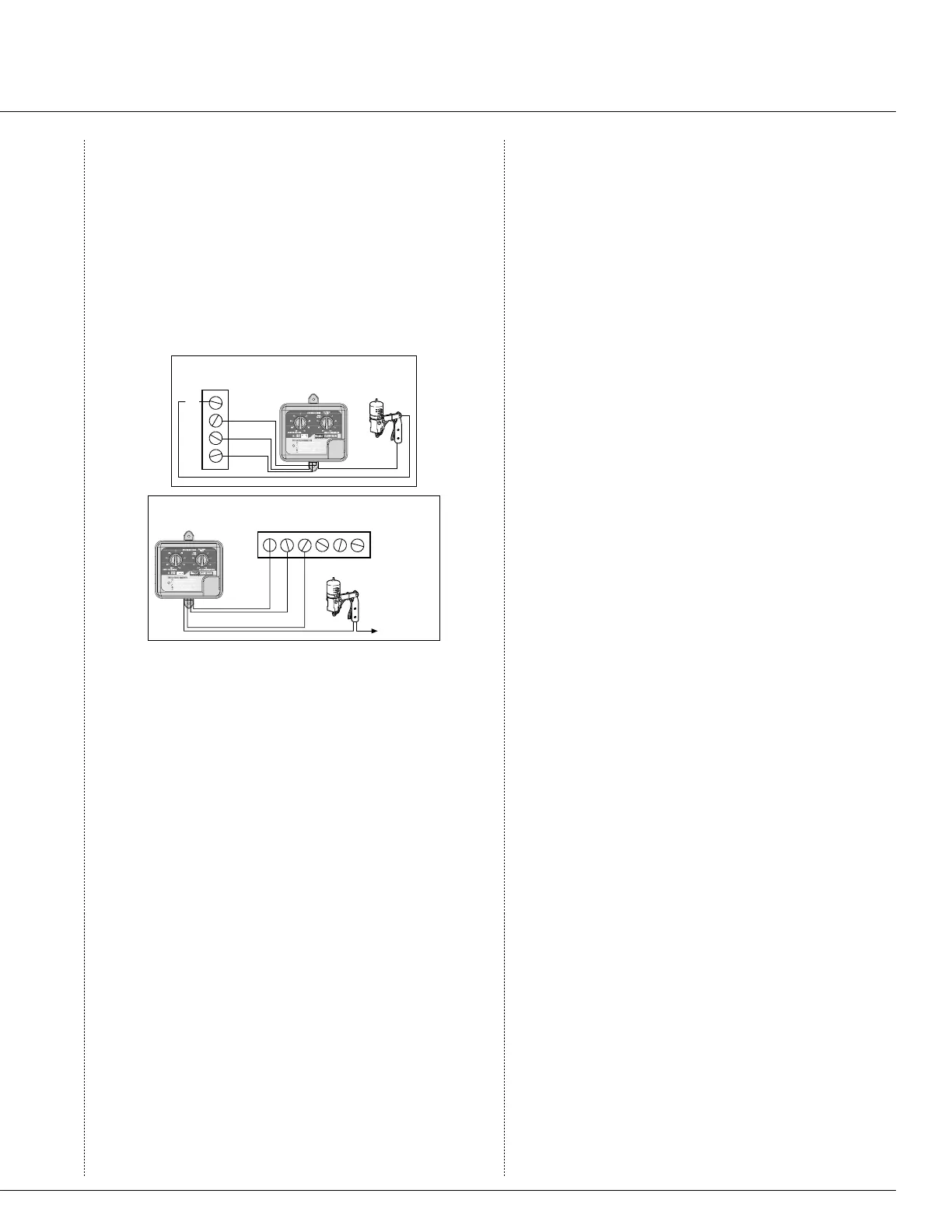

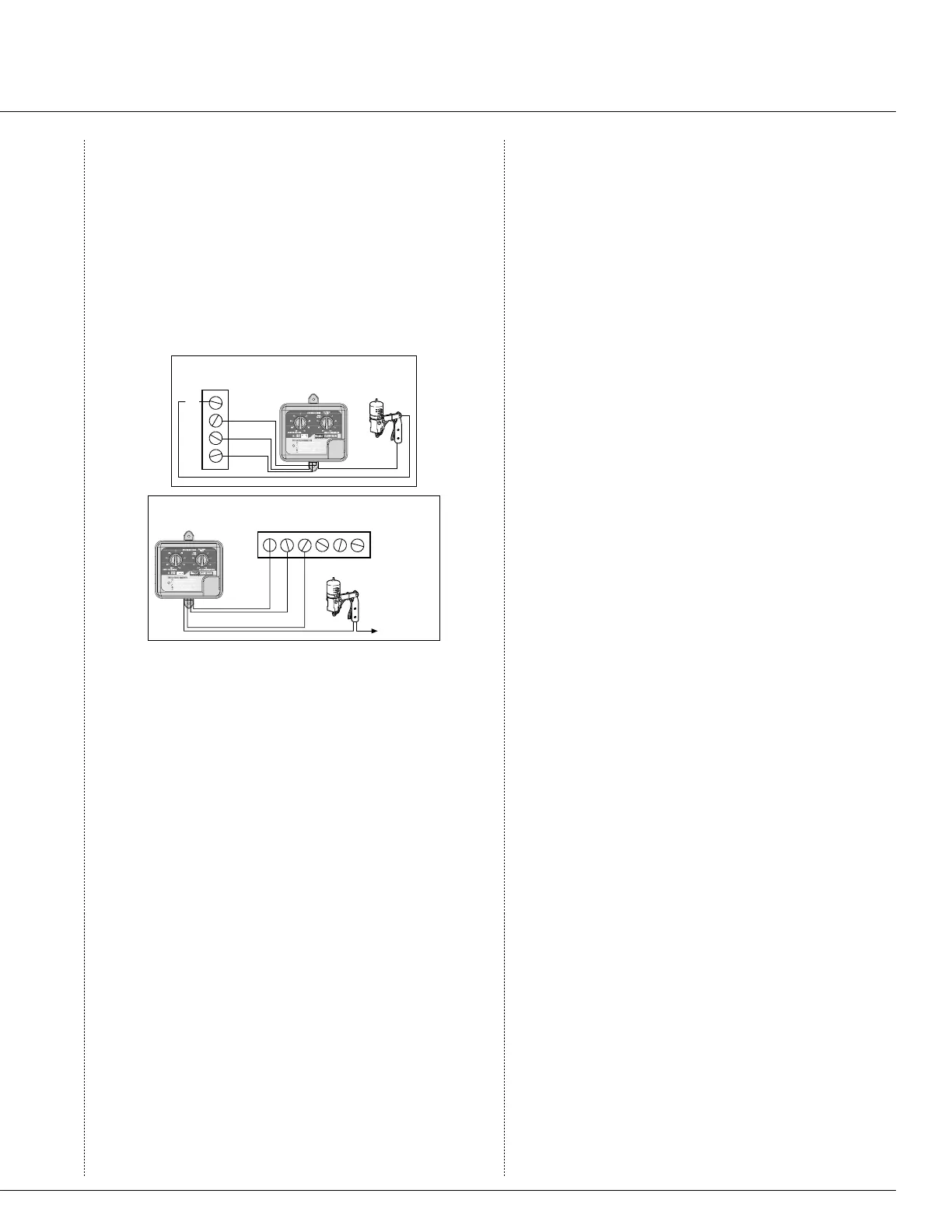

Wiring When Using Multiple Sensors

The Flow-Clik™ can be wired to a controller al-

ready using another Hunter sensor (i.e. Rain-Clik™,

Wind-Clik

®

, Freeze-Clik

®

, etc.) or other micro-switch

type sensors. It is important to make sure that, when

using multiple sensors, they are connected in series.

Hunter Controllers

Mini-Clik

AC

AC

SEN

Interface Box

Y

Y

W

W

SEN

1 2 3

Interface Box

C

Common Wire

to All Valves

AC AC

Y

W

Mini-Clik

Y

W

Other Controllers

System Considerations

Proper irrigation system design and operation assures

optimum performance of the Flow-Clik in monitoring

for potential high flow conditions. It is important to

understand that the Flow-Clik is primarily designed to

shut off the irrigation system in the event of a cata-

strophic system failure such as a main line or lateral

line break. However, depending upon the design of the

irrigation system, the Flow-Clik can offer increased

protection when components such as sprays or rotors

are damaged or removed due to vandalism. The follow-

ing may be helpful in making your Flow-Clik System

operate at its optimum level.

Proper Irrigation System Design

Generally, the Flow-Clik is designed to shut off the

irrigation system when a high flow condition is identi-

fied. A high flow occurs when the actual flow rate

through the system exceeds the “learned” flow of the

highest flow zone. If a wide variation in flow rates ex-

ist between the highest flow zone and the lowest flow

zone, the Flow-Clik may not sense an over flow condi-

tion if damage occurs within the low flow zone(s). For

example, if an irrigation system has a rotor zone that

operates at 18.9 GPM, and a drip zone that flows at

5 GPM; any damage to the drip zone components may

not result in high enough flow rate for the Flow-Clik to

sense an over flow condition.

The more balanced the irrigation system is designed,

the more protection will be provided by the Flow-Clik.

Zones should be designed so that they operate at simi-

lar flow rates.

Note: To assure proper operation, the flow for the highest

flow zone should not exceed 75% of the maximum

system flow.

Mainline Pressure Fluctuation

Some water sources may have varying pressure de-

pending upon the demand for water upstream of the

point of connection. During times of heavy demand,

system pressure through the mainline may drop. A

decrease in mainline pressure will result in a decrease

in flow rates throughout the system. If the Flow-Clik

calibration procedure takes place during a period of

time which pressure is at its lowest point, an increase in

pressure at the point of connection may result in system

flow rates that exceed the calibrated “high flow”. As a

result, the Flow-Clik may shut the system down prema-

turely even though the system is functioning normally.

Note: If pressure fluctuations at the point of connection

in excess of 10 psi are expected, it is recommended

that a pressure regulator be installed on the mainli-

ne or at the master valve.

Proper System Maintenance and Operation

It is important that your irrigation system be main-

tained and is functioning properly for optimum perfor-

mance. Check your irrigation system for any broken

components or leaks also, make sure that all sprinklers

are operating within the pressure ranges recommended

by the manufacturer.

Note: Before calibrating the Flow-Clik to your system, it

is very important that the irrigation system be in

good working condition. Irrigation system leaks,

broken sprinklers, zones operating outside specified

pressure ranges, will have a negative effect on the

performance of the Flow-Clik.

Flow-Clik

™

Sensor

Loading...

Loading...