Pre-Installation Manual for i-Series Machines v387 Start-up Preparation 3-1

START-UP PREPARATION

This chapter contains information about preparing for machine start-up.

Pre-Installation Requirements

Review the pre-installation requirements.

Before your full service distributor or Hurco customer service department arrives to install

the machine, complete the following requirements:

• All machine equipment is located at the final installation site.

• Machine is positioned for installation, on a suitable foundation that will bear

its weight.

• Machine is rough-leveled.

• Utilities (air and electricity) have been made available, but are not connected

or turned on.

• Flood coolant tank, tubing, chiller, and coolant pump motor are placed near

the machine base.

• Acquire tool retention knobs (Machining Centers). Please refer to the Model-

specific Specifications document for details.

• VERY IMPORTANT! Lubrication and fluids are available:

A Hurco-certified Service Engineer will visit your site and prepare the machine for start-

up.

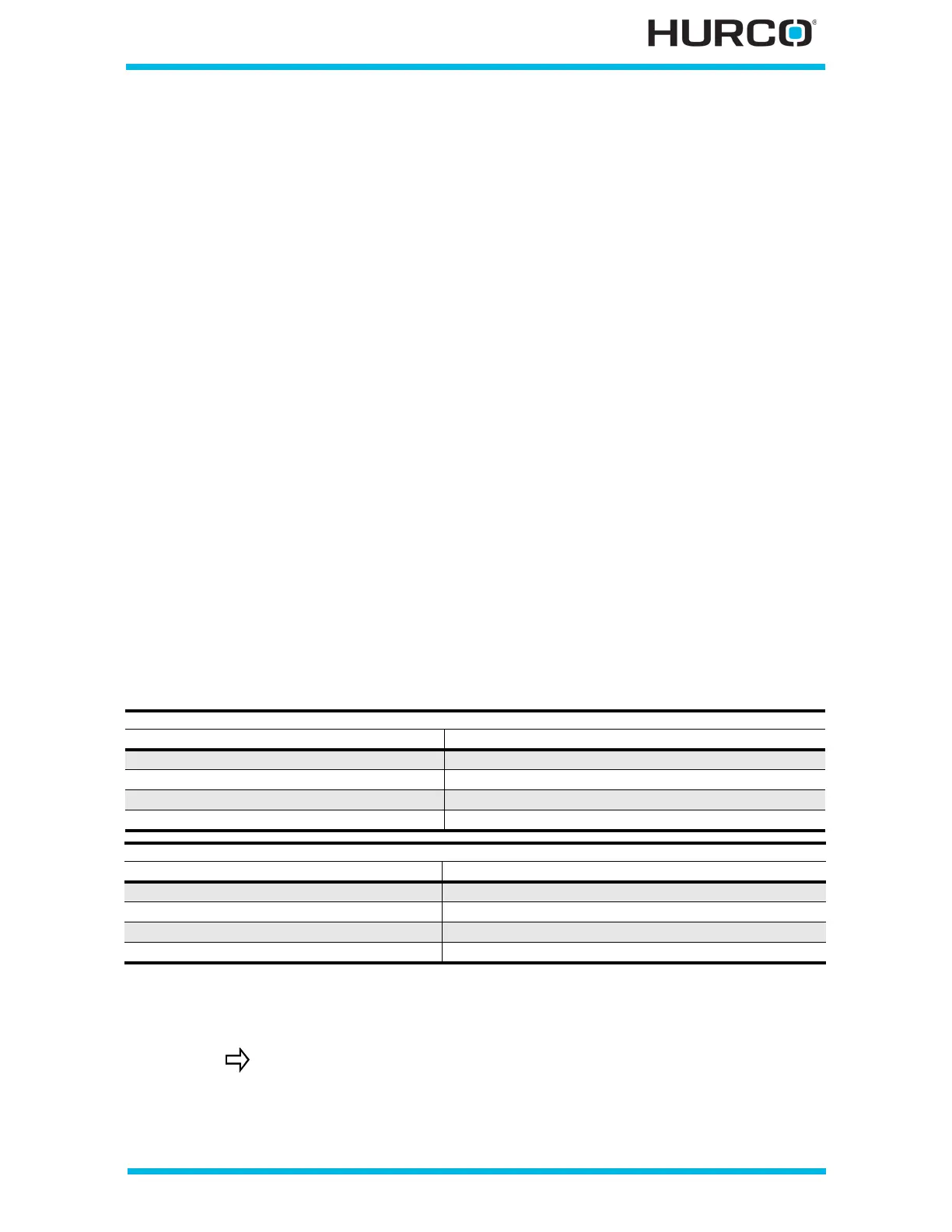

Turning Centers

Component Available Lubrication

Hydraulic Tank fluid, equivalent to ISO. VG 32

Chuck and Tailstock grease for plug points

Turret oil, equivalent to ISO VG-100-150

Way Lube Systems

oil, equivalent to Waytac Oil #68

Machining Centers

Component Available Lubrication

ATC Components and Drives grease, equivalent to Amolith Grease #2 EP

Air Line Lubes and Spindle Oil Coolers oil, equivalent to American Ind. Oil #32

Way Lube Systems and Spindle Taper oil, equivalent to Waytac Oil #68

Air/Oil Unit for Tool Release Cylinder oil, equivalent to Teresso 32

It is the customer’s responsibility to provide tooling, coolant, and

appropriate lubrication and hydraulic fluid.

Loading...

Loading...