SERVICING THE INDIVIDUAL PARTS

D

1

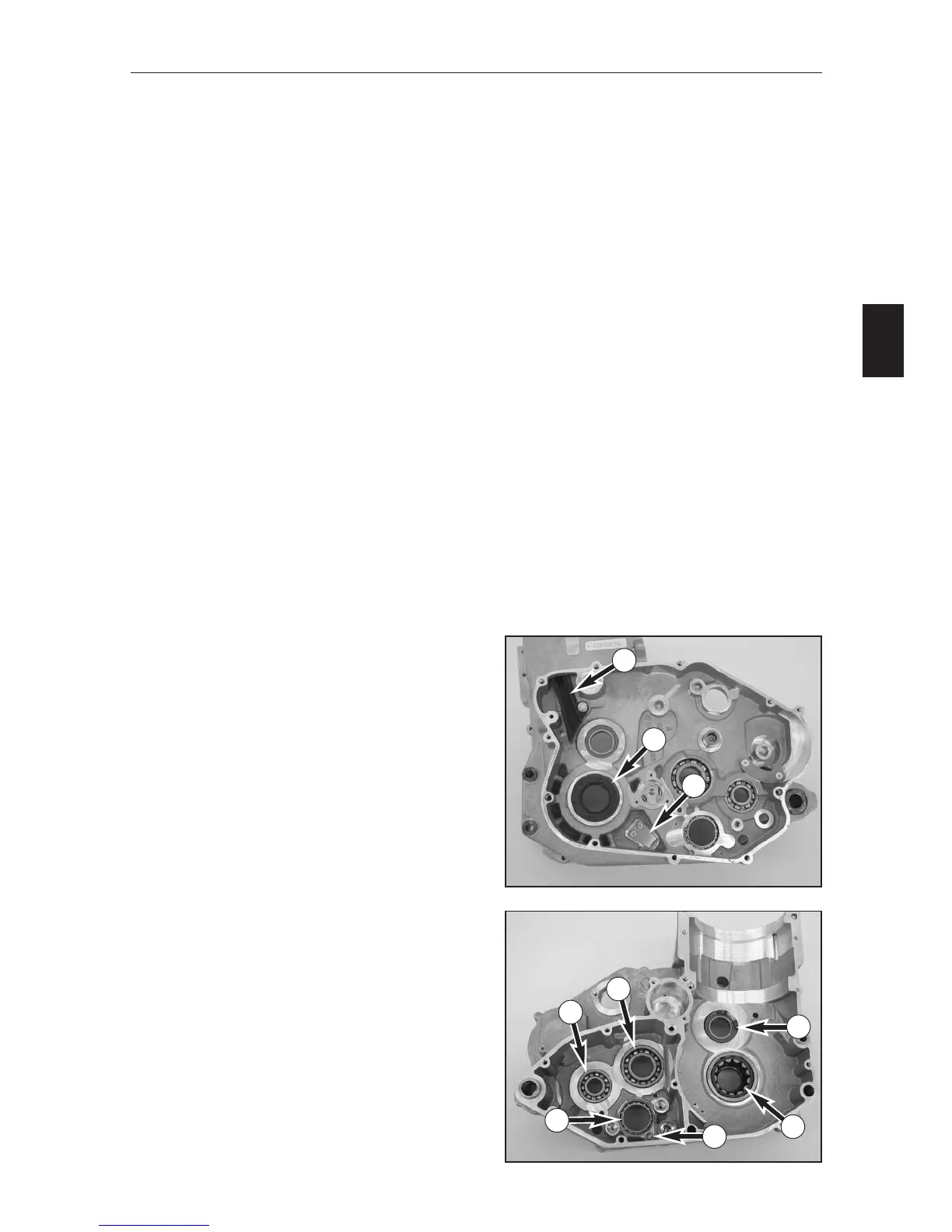

LEFT HOUSING HALF

– Remove the shaft seal ring (1) from the crankshaft.

–Dismount the chain guide (2).

–Dismount the diaphragm valve (3)

– Remove the circlip (4) from the idler shaft bearing.

– Remove the retaining bolt (5) on the shift drum

bearing.

– Heat the housing half in the oven to approx. 150° C;

the bearings will fall out of the bearing seats

automatically at a housing temperature of approx.

150° C.

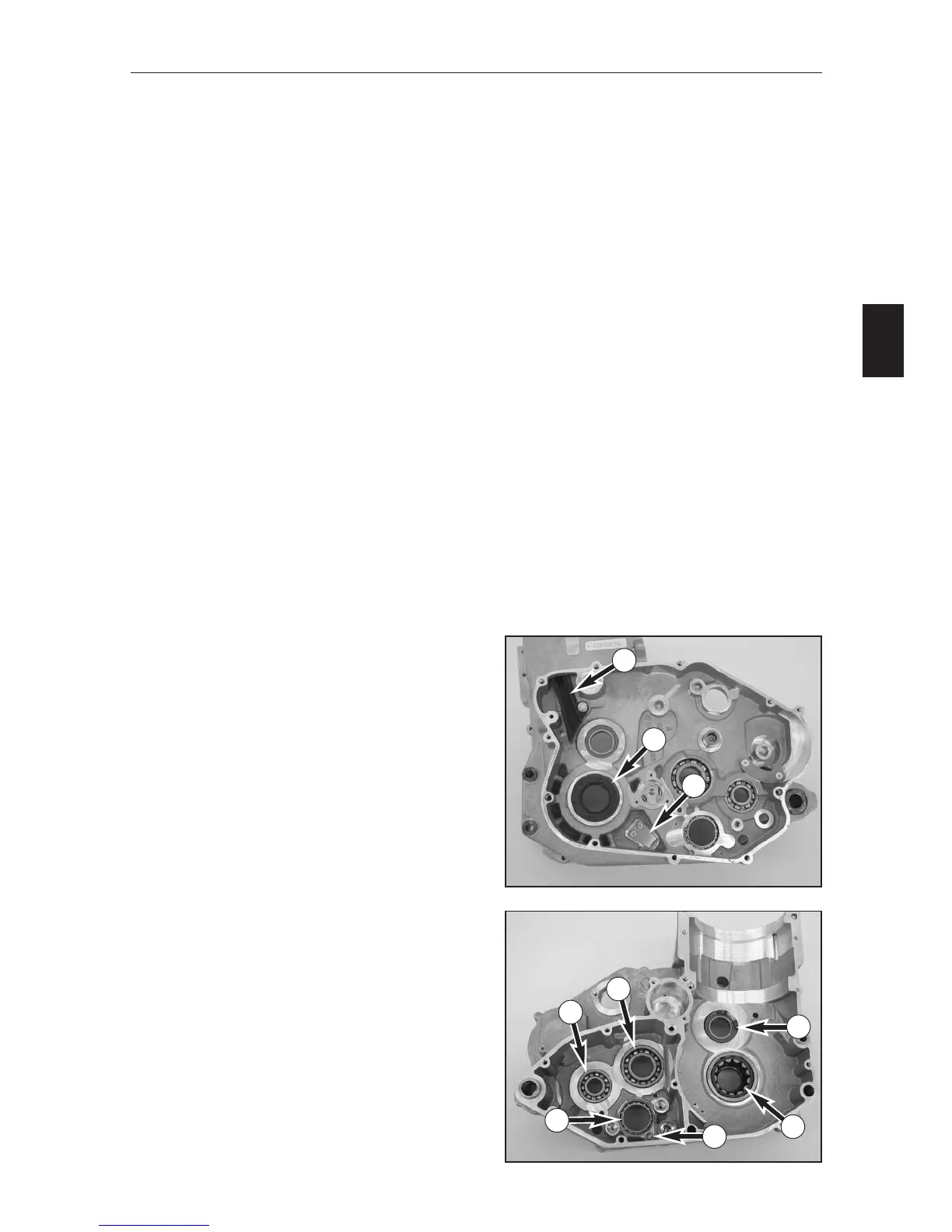

Roller bearing for the crankshaft (6)

Press in a new roller bearing from the inside up to the

stop with a suitable mandrel.

Grooved ball bearing for the main shaft (7)

Press in a new grooved ball bearing from the inside up to

the stop.

Grooved ball bearing for the countershaft (8)

Press in a new grooved ball bearing from the inside up to

the stop.

Grooved ball bearing for the shift drum (9)

Press in a new grooved ball bearing from the inside up to

the stop.

The needle bearings in the starter idler and freewheel

usually do not need to be replaced since they do not

wear easily.

IMPORTANT INFORMATION ON WORKING WITH THE ENGINE CASE

Generally, all gaskets, O-rings, crankshaft bearings and the transmission shaft bearings should be replaced

when repairing the engine. In addition, all of the parts need to be cleaned thoroughly, removing any residual

sealant from the sealing areas.

Any bearings removed with an extractor need to be replaced.

Read the following section before you start to work. Establish the assembly order to allow you to insert the

bearings after heating the engine case halves only once.

To press or knock out the bearings, place the respective housing half on a flat surface (first remove the dowels),

placing the housing half on the sealing area to prevent it from being damaged. A wooden panel makes a good

base.

If possible, do not drive in any bearings or shaft seal rings; if you do not have a pressing tool, only drive them in

with a suitable mandrel, using the utmost care. The cold bearings will automatically drop into the bearing seats

at an engine housing temperature of approx. 150° C. If necessary, tap the housing half on an even wooden

surface, if any bearings stay in their seats, press out with a suitable mandrel.

Always press or drive in new bearings at the outer ring of the bearing, otherwise the bearings or their running

surfaces will be damaged.

After the housing half has cooled down, check the bearings for a tight fit; if they are not firmly seated after

cooling down they may turn in the engine case when they warm up. If this happens, the engine case must be

replaced.

1

2

3

4

5

6

7

8

9

Loading...

Loading...