SERVICING THE INDIVIDUAL PARTS

D

12

CYLINDER HEAD

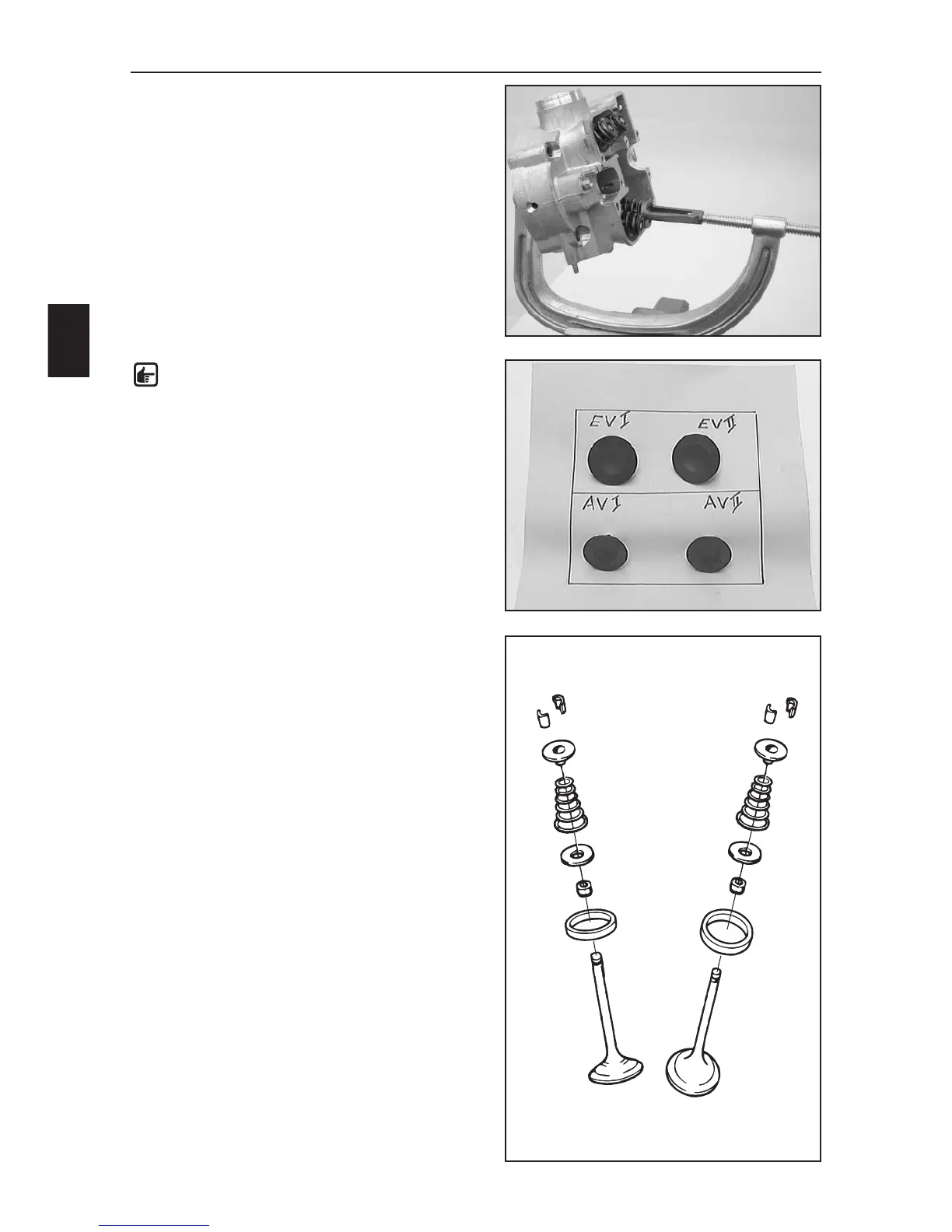

– Remove the chain tensioning rail.

– Remove the 4 valves with the special tool

590.29.019.000.

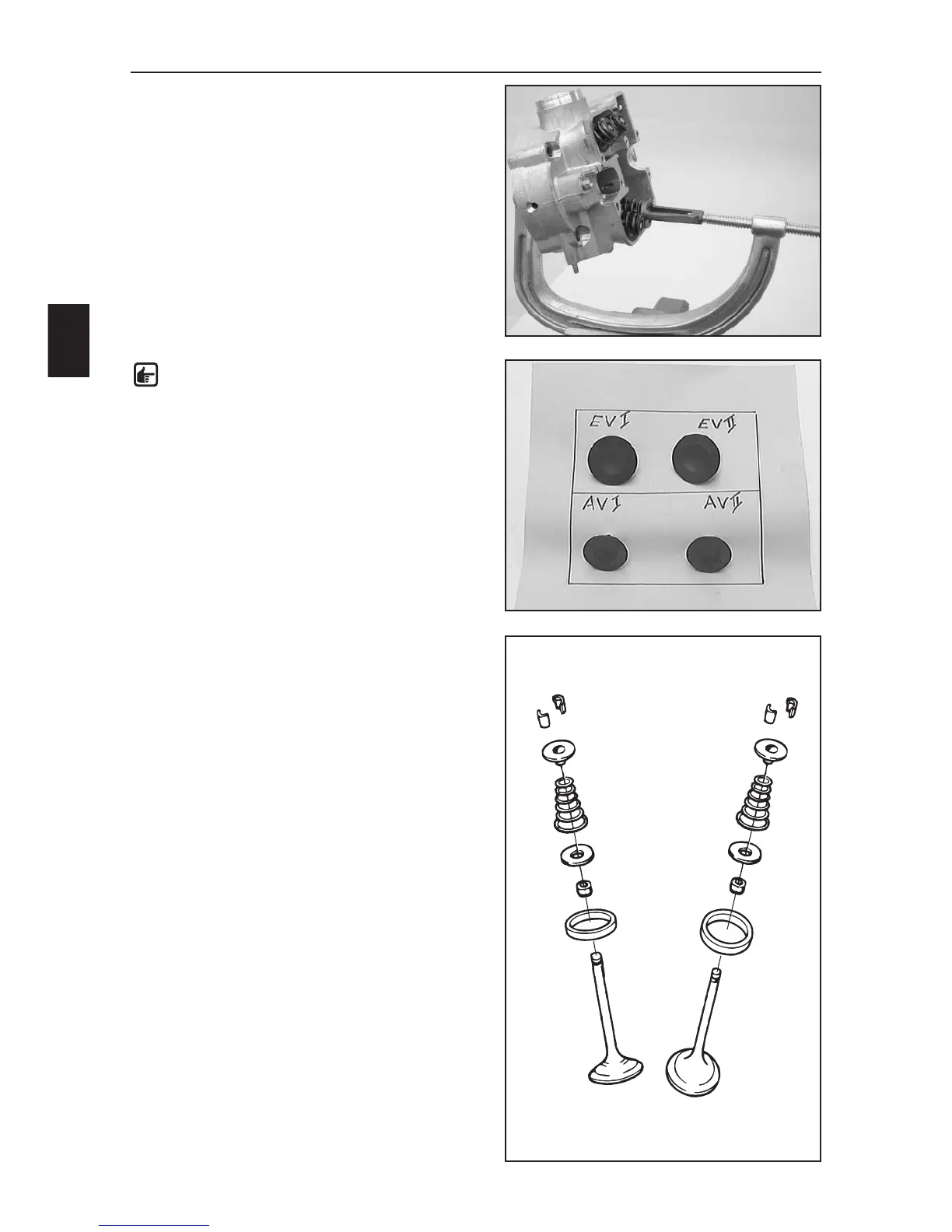

NOTE: if you are mounting the used valves

again, they must be mounted in the same valve

guide as before. For this purpose, place the

valves in a box, marking the position they were

mounted in the cylinder head (see photo).

– Remove the valve spring retainer (1) and the valve

springs (2) from the cylinder head.

– Remove the spring retainer (3) and pull the valve shaft

seals (4) off of the valve guides.

Sealing area

Check the spark plug thread and the valve seats for

damage or cracks. Use a straight edge and a feeler

gauge to measure the sealing area to the cylinder for

distortion. Max. distortion 0.10 mm.

Valve seats

The valve seats may not be impacted. Width of sealing

seat: intake max. 1.50 mm; outlet max. 2.00 mm. Reseat

the valves if necessary.

Valves

Check the valve disk for wear and runout. The valve disk

runout should not exceed 0.05 mm. The valve seat may

not be impacted. The sealing area should be in the

middle of the valve seat. The valve shaft is hard-chrome-

plated. Wear usually occurs at the valve guide.

1

2

3

4

1

2

3

4

Loading...

Loading...