Pg 1.5 S23P 2001e

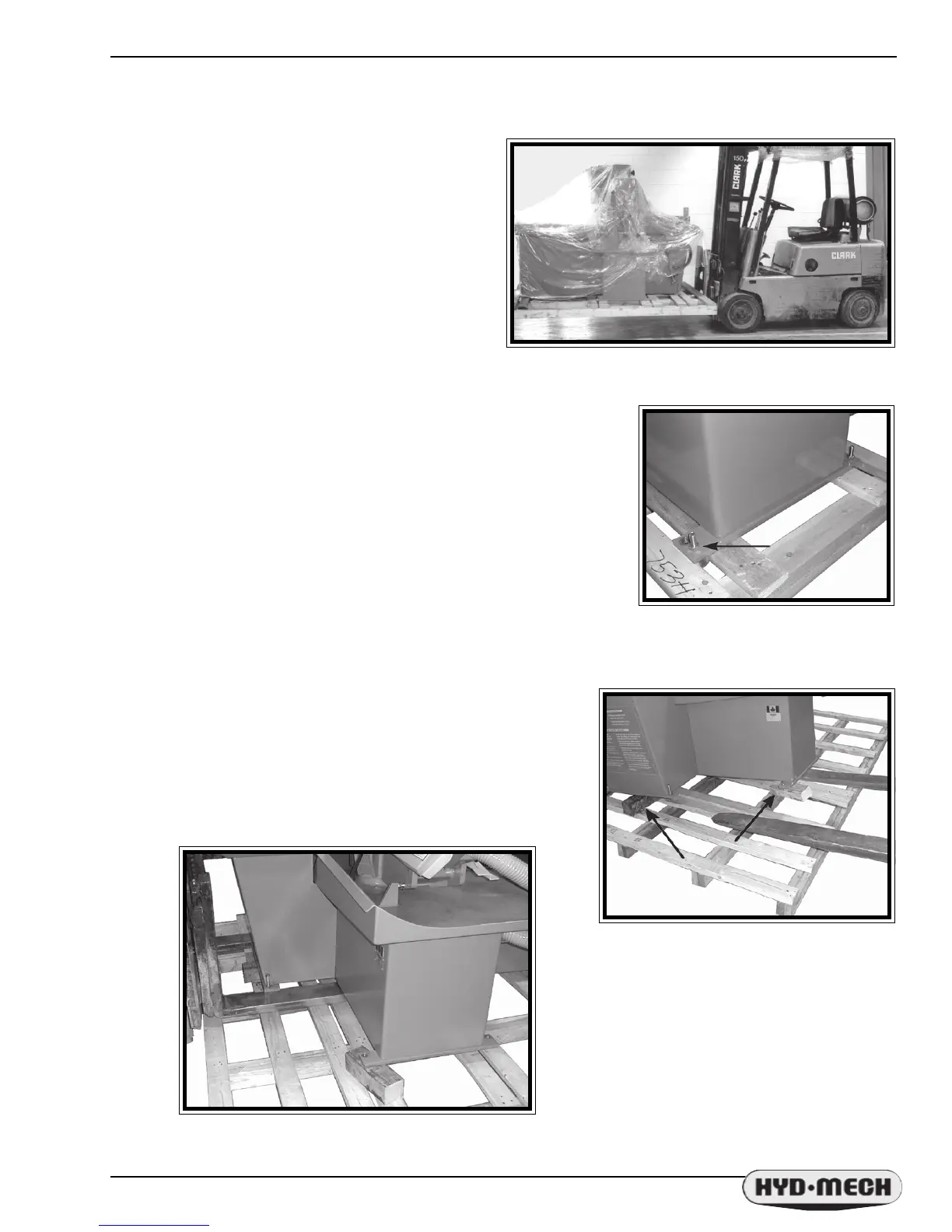

LIFTING THE S-23P

The S-23P is shipped with a shipping pallet

attached to the saw. When lifting the pallet with a lift

truck make sure that the load is firmly balanced. The

following photo shows a lift truck lifting the saw and

pallet from the correct side. The pallet length dimension

is 84". Minimum fork length of 72" is recommended to

safely lift the pallet.

WRAPPED FOR SHIPPING

The S-23P is shrink-wrapped for shipping from our

plant. Remove the wrapping from around the saw.

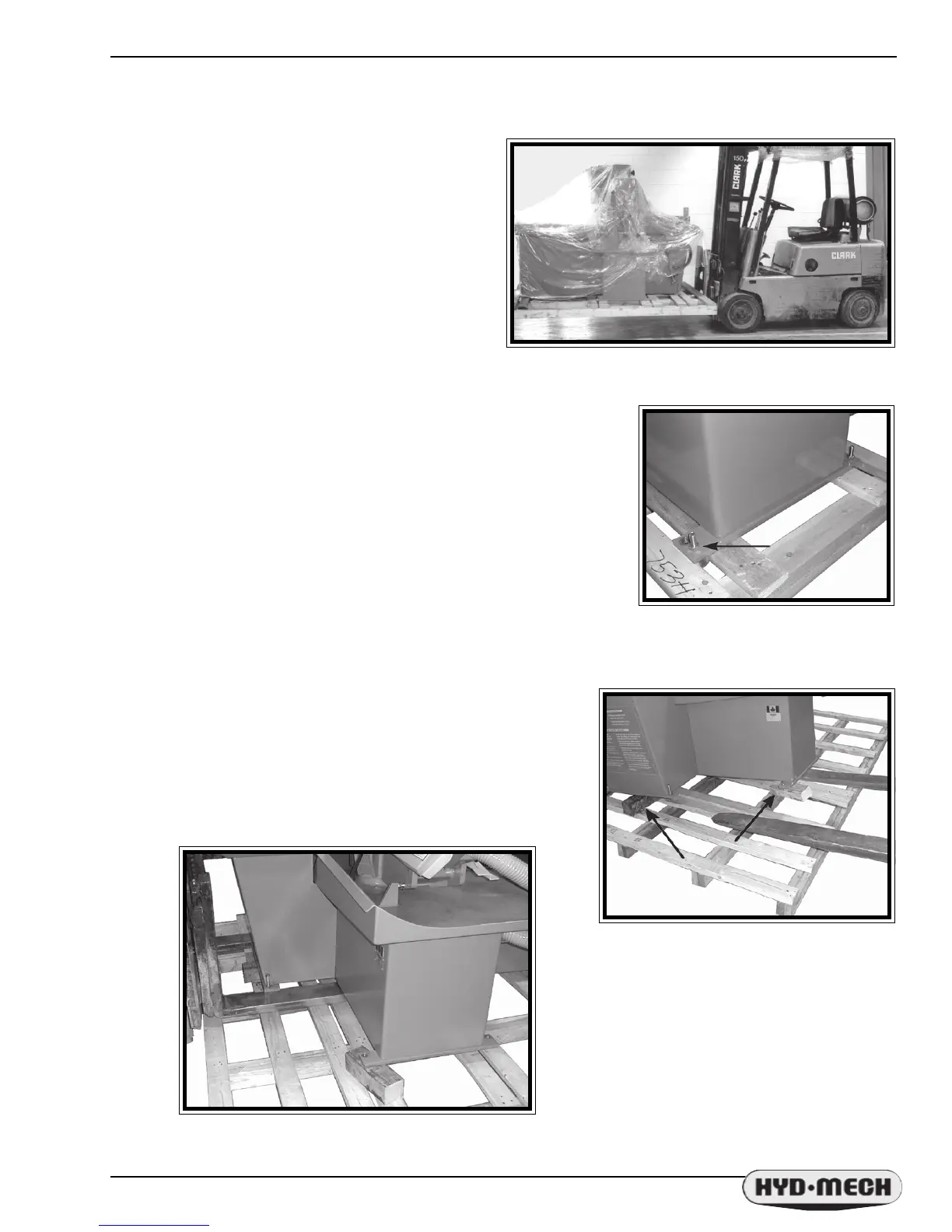

Complete the inspection for signs of damage. The

photo shows the floor mounting plates located at the

corners of the saw. Undo the bolts that hold the saw to the pallet. Retain

these bolts to use for levelling. The larger diameter hole is used for

retaining during shipping and for use with concrete floor anchors. The

smaller diameter, threaded holes at each corner are used for levelling the

saw properly.

REMOVING THE SAW FROM SHIPPING SKID

Lift the right (drive) side of the saw as shown with a lift truck and

place two blocks under the saw as shown. With a lift truck (fork

length 5' min, rated for 2000lbs minimum), lift the saw from the skid

at the FRONT of the machine as shown and place it where required.

Lifting the packaged S-20 Series II with a lift truck.

Bolt holding the saw to the skid (4

places).

Blocks placed under the saw.

Lifting the machine with a lift truck from the front

of machine.

Loading...

Loading...