Pg 2.17 S22P/S23Pa

CHART EXAMPLE #1

We will use the parameters chart to set up the saw for cutting 8" (200mm) Diameter #1045 Carbon Steel.

STEP 1,

DETERMINE EFFECTIVE MATERIAL WIDTH - W ( inches ) or (mm)

Eff

ective material width, W (in.) for most common shapes of materials, is the

widest solid part of the material to be in contact with blade during cutting. For

simple shapes, as illustrated on the chart, this can be directly measured. For

bundles of tubes and structurals, measuring the effective width is difficult.

Effective width is 60% to 75% of the actual material width.

NOTES:

1) Both effective material width and guide arm width are used in setting the

saw.

2) Guide arm width is the distance between the guide arms and is used in STEP 2.

3) Effective material width, as determined here in STEP 1, can be thought of as the average width of material

“seen” by each tooth, and it is used in STEPS 3 and 4. In Example #1, for an 8" (200 mm) diameter solid,

Effective Material Width is 8" (200mm).

STEP 2, SET FEED FORCE LIMIT

The Feed Force Limit is the maximum amount of force with which the head is allowed to push the blade into the

work-piece. FEED FORCE LIMIT should be set with the head in the down mode, according to the label.

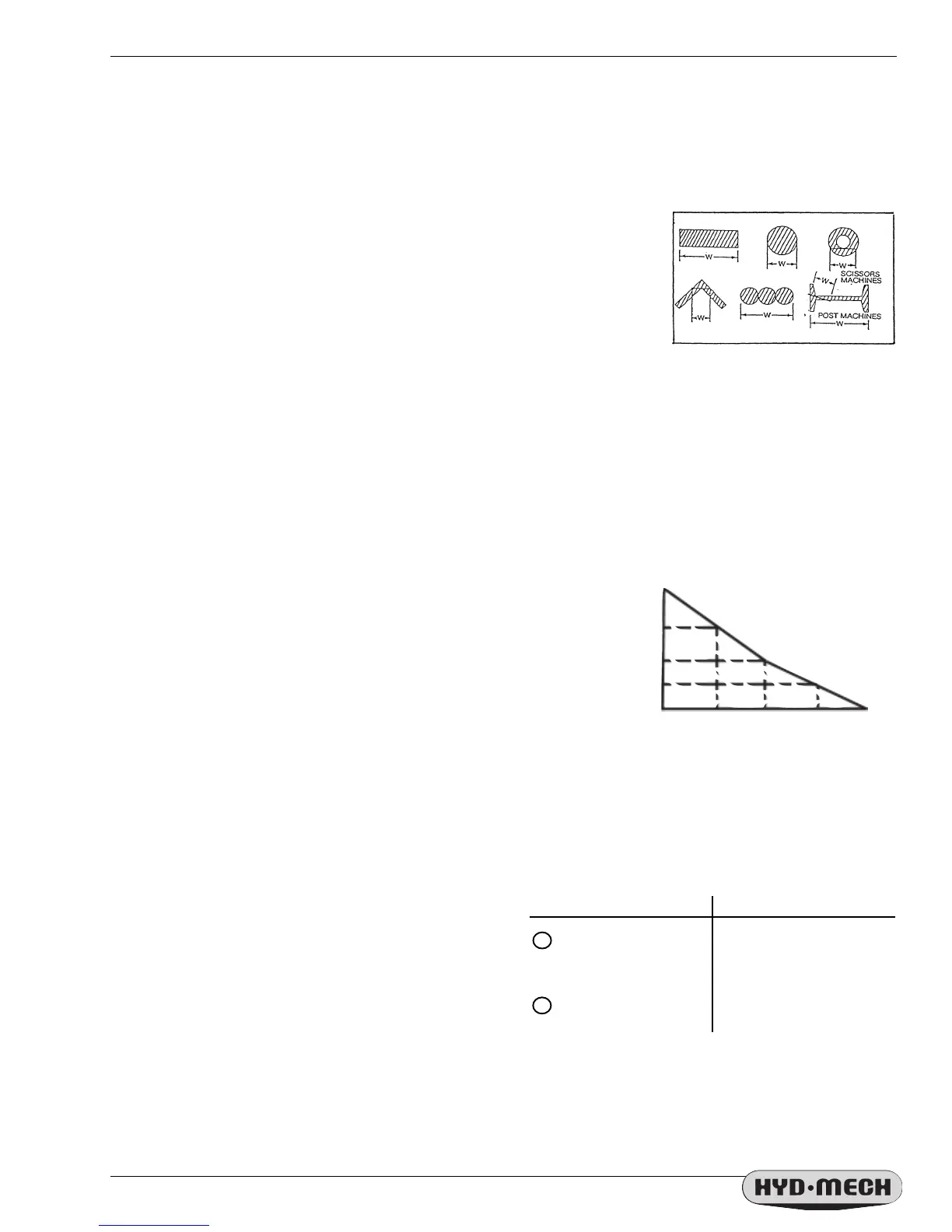

CUTTING SOLIDS

For cutting solids, the wider the section, the less FF

should be set, to avoid blade overloading. See the graph.

EXAMPLE: When cutting a solid which is 1/2 of

machine capacity using the graph, locate 50% on the

horizontal line and travel upwards to the plotted line and

then travel directly across to the vertical FF Setting line.

The point that you have arrived at shows a setting of 40%

for a piece 50% of capacity.

CUTTING STRUCTURALS

A reduced Feed Force Setting is used when cutting

structurals:

For structurals, a blade finer than Optimum can be

used for more efficient cutting.

If a finer than optimum blade is going to be used, Feed

Force Setting should be reduced even further.

Material Width Chart

1 OPTIMUM PIT1 OPTIMUM PIT

1 OPTIMUM PIT1 OPTIMUM PIT

1 OPTIMUM PIT

CHCH

CHCH

CH

FROM STEP 3 FROM STEP 3

FROM STEP 3 FROM STEP 3

FROM STEP 3

20%20%

20%20%

20%

0%0%

0%0%

0%

2 PIT2 PIT

2 PIT2 PIT

2 PIT

CH FINERCH FINER

CH FINERCH FINER

CH FINER

THAN OPTIMUM THAN OPTIMUM

THAN OPTIMUM THAN OPTIMUM

THAN OPTIMUM

BLBL

BLBL

BL

ADEADE

ADEADE

ADE

FF SETTINGFF SETTING

FF SETTINGFF SETTING

FF SETTING

FF

FF

F

or OPTIMUM BLor OPTIMUM BL

or OPTIMUM BLor OPTIMUM BL

or OPTIMUM BL

ADE SELECTIONADE SELECTION

ADE SELECTIONADE SELECTION

ADE SELECTION

, see STEP 3, see STEP 3

, see STEP 3, see STEP 3

, see STEP 3

100%

% of FF 70%

SETTING

40%

20%

0 25% 50% 75%

MAT’L WIDTH as % os CAPACITY

Loading...

Loading...