Pg 3.24 S23P

BLADE CHANGING PROCEDURE, CONTINUED

9A. As the blade tracking will stay fairly constant, it should be checked occasionally as shown on the drive

wheel tracking photo below. The blade teeth should protrude from .195" to .210" (5mm to 5.3mm) from the face

of the blade wheels. If the tracking requires adjustment, follow the instructions below.

BLADE TRACKING ADJUSTMENT

10. First, inspect the blade wheels for wear or damage and repair as

required. Blade tracking adjustment should always begin at the wheel

where the tracking is farthest out of specification. Using the

instructions below, adjust the worst wheel, jog the blade and recheck

both wheels. Repeat this process until both wheels are within

specification.

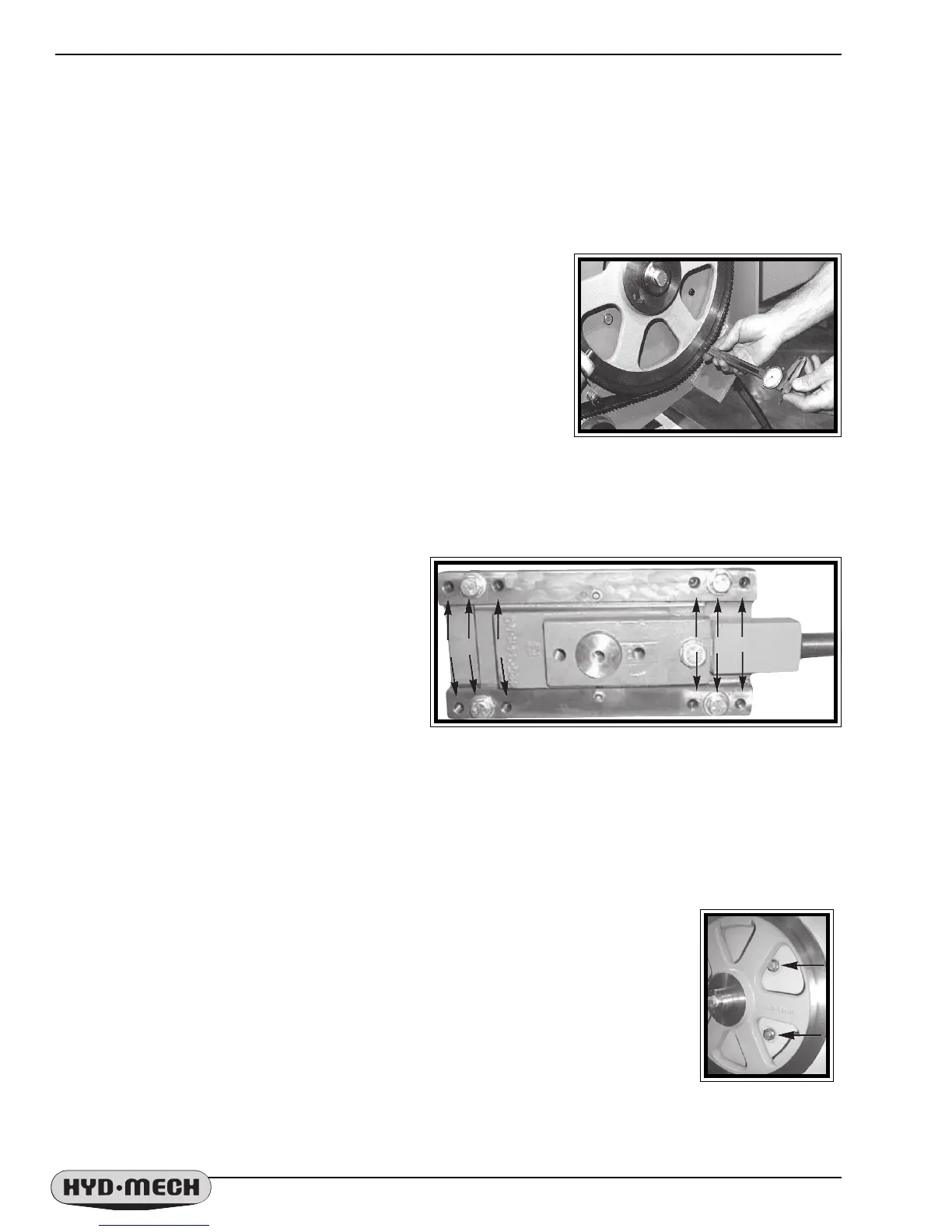

10A. Idler Wheel Adjustment

The tracking is adjusted by regulating the "push"

set screws and the "pull" hex bolts. Before

making any adjustments, bolts "A & B" should be

loosened but remain snug. This will allow easy

movement for the slide assembly. It should be

noted that most adjustments can be made with

the "B & D" bolts. Loosening bolts "A" and

turning in set screws "C" by equal amounts will

move the blade off the wheel. Loosening bolts

"B" and turning in set screws "D" by equal

amounts will move the blade on to the wheel.

After each "C" or "D" adjustment, tighten bolts "A

& B", run the blade and then check the tracking.

10B. Drive Wheel Adjustment

On the wall behind the drive wheel are two adjusting bolt assemblies and two hex bolts.

Loosen all four of them with a 3/4" socket and turn the larger hex head bolts 1/4 turn with

a 1 1/8" socket and extension and then tighten the two bolts in the assemblies, then

tighten the two hex bolts et the left. Turning the 1 1/8" bolts clockwise will pull the blade

on to the wheel and turning counter clockwise will push the blade off. Each 1/4 turn will

move the blade approximately .02".

11. Check the blade brush adjustment (next page) to be sure the blade is being cleaned

properly.

Checking the tracking.

Tracking adjusting bolts & set screws.

D B D

C A C

Drive wheel

tracking bolt

assemblies.

Loading...

Loading...