Pg 3.25 S23P

BLADE GUIDE ADJUSTMENT

At the bottom of the guide arms are the carbide blade guide assemblies, the

photo below shows the carbide locking handle. These assemblies will need to be

adjusted occasionally as the carbide pads become worn. To adjust properly,

follow this simple procedure. Loosen the hex nut on the locking handle with a 9/16

wrench and turn the handle clockwise until it rests against the coolant tap on the

idler guide arm or the roll pin on the drive guide arm. Turn the set screw clock

wise with a 3/16 allen key until tight and then loosen 1/8 of a turn and tighten the

hex nut. This should put just enough pressure on the blade to permit you to push

the blade down approximately 1/8".

Idler guide arm carbide

locking handle in the

locked position.

BLADE BRUSH ADJUSTMENT

The S-23P leaves the factory with the blade brush adjusted for maximum life of the

brush. This setting places the ends of the blade brush wires so as to contact the blade at

the bottom of the blade gullets. The plastic drive wheel that is driven by the drive wheel

face should be held against the blade face with the minimum force that is necessary. As

the blade brush wears it is necessary to periodically readjust it.

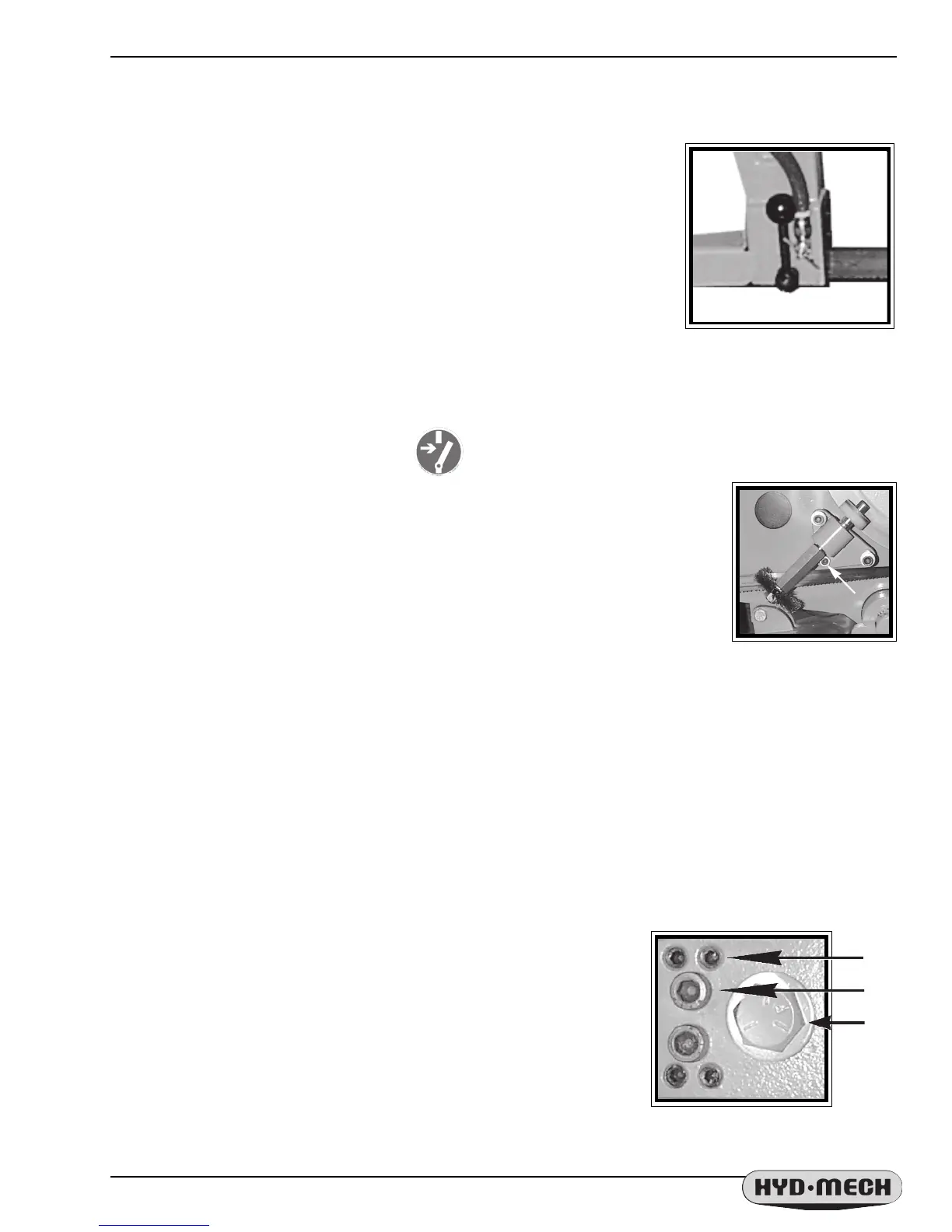

As shown, there are two springs on socket head screws holding the brush assembly

against the blade. There is also an adjusting socket set screw with a hex nut on it.

Loosen the hex nut with a 9/16" wrench and turn the set screw counter clockwise with a

3/16" allen key. This will move the brush closer to the blade. Adjust the set screw so that

the brush cleans to the bottom of the blade gullets and tighten the hex nut.

Blade brush adjusting

screw & hex nut.

ANGLE BRAKE ADJUSTMENT

The clamping force on the swivel brake can be adjusted to ensure that the Head is held securely and does not

move during cutting. The brake handle should be adjusted so that it does not "bottom out" or hit it's movement limit,

yet holds the head securely.

ANGLE BRAKE ADJUSTMENT PROCEDURE

STEP 1 Loosen locking cap screws "B" with a 1/4 allen key.

STEP 2 Tighten all 4 set screws "A" until snug with a 5/32" allen key.

STEP 3 Back out the "A" screws 1/4 of a turn.

STEP 4 Tighten the locking cap screws "B".

STEP 5 Swing the head to 45

o

and back to ensure that the head moves

freely and does not bind on the pivot surfaces. Continue to step 6 if

necessary.

STEP 6 Adjust the clamping force bolt "C" with a 3/4" wrench. If not

tightened enough, the locking handle will "bottom out" and not hold the

head firmly.

A

C

Angle Brake

Adjustment Screws.

B

Loading...

Loading...