24

Note; if the sensor alarm is to keep generating then contact us quoting the

problem and the part n

o

.

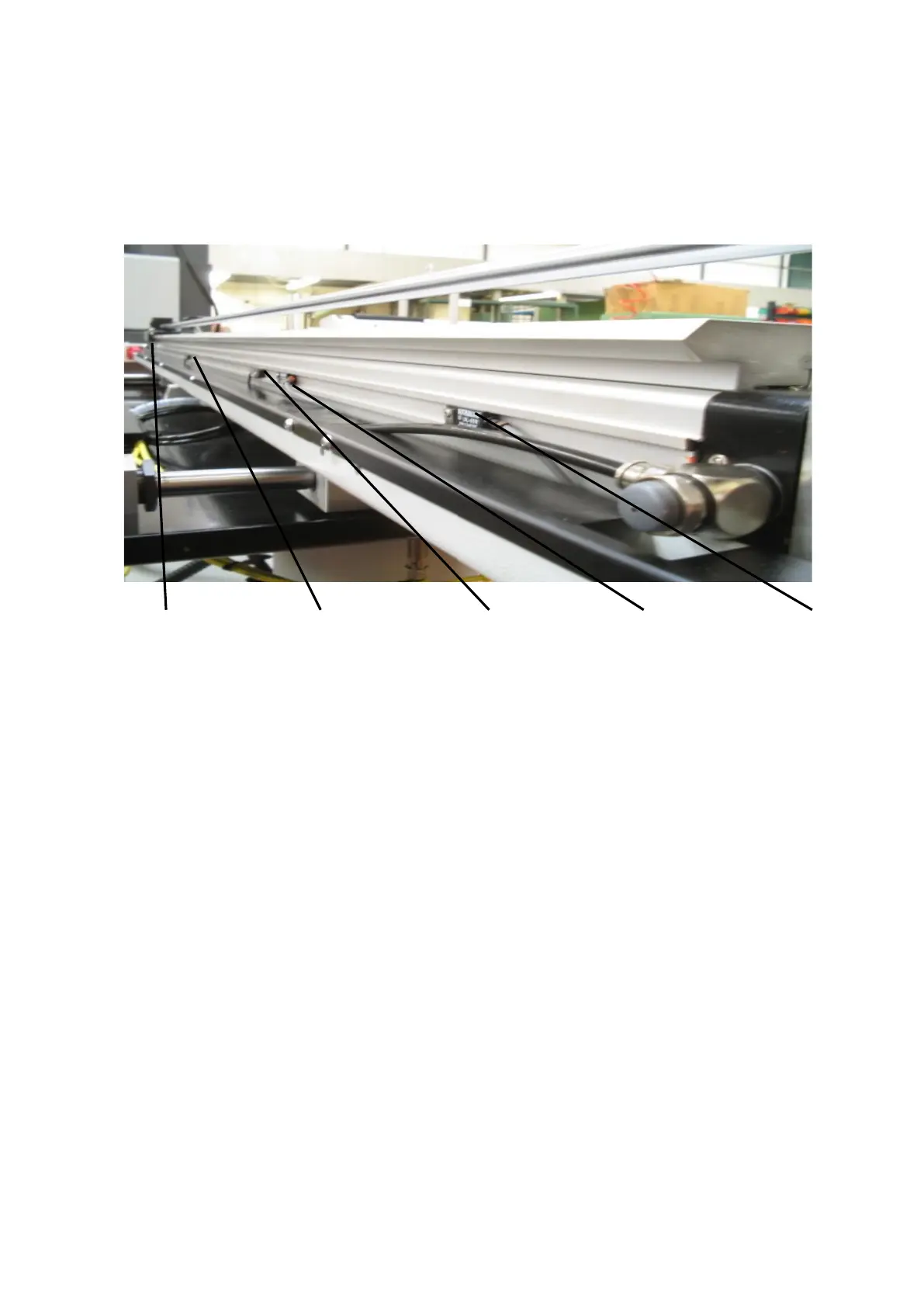

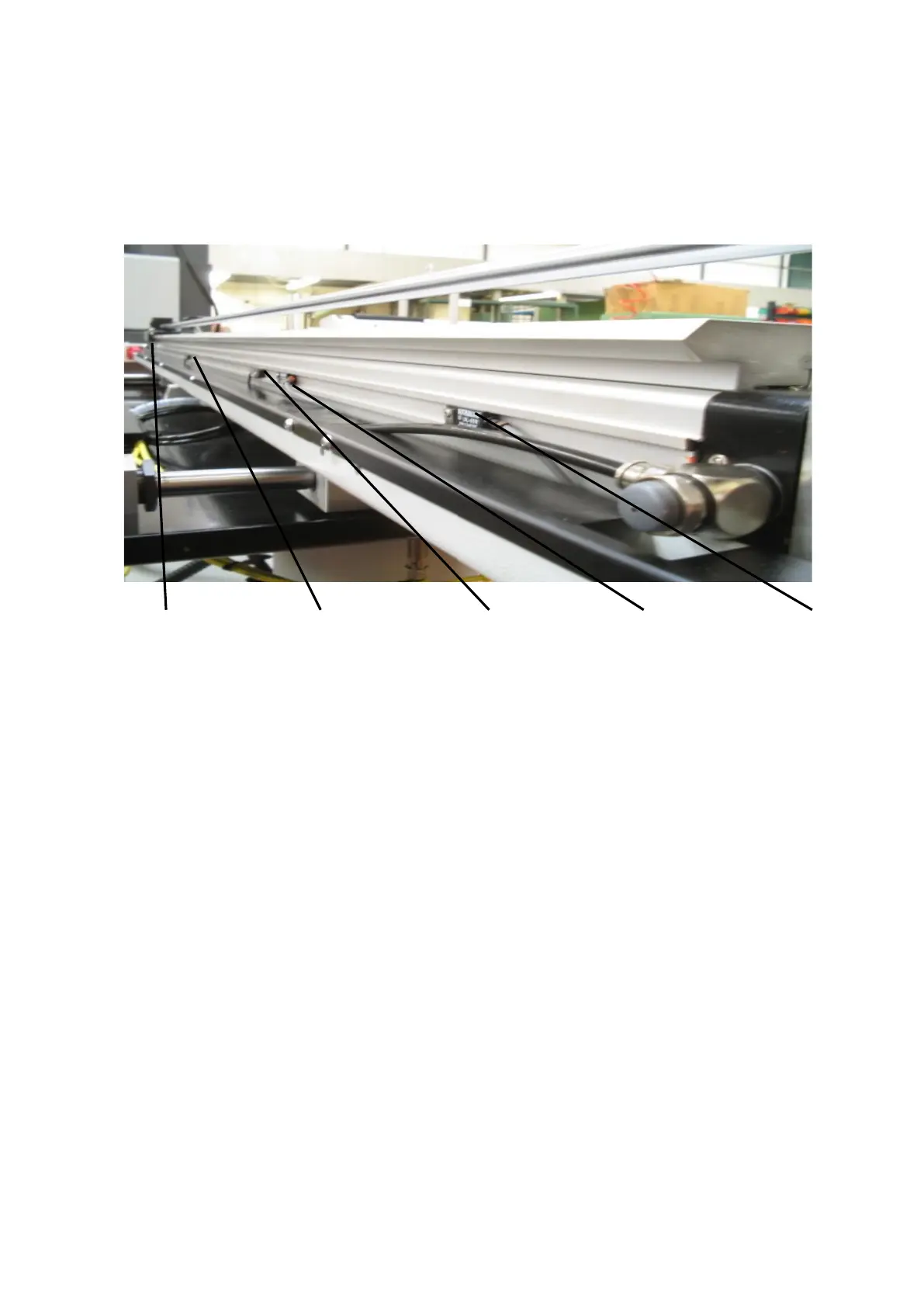

5.6 LOCATION OF CYLINDER SENSORS

Figure 25

Sensor 1 Sensor2 Sensor3 Sensor4 Sensor5

Pusher Home Mis-load Last Component Eject Remnant Pusher

E.O.B Forward

Picture of sensor may not be same as on machine.

Sensor 1

Pusher Home: this sensor is set directly below the Pusher carriage and is actuated

when Pusher is in its fully back position (home position) then checked on installation

and MUST not be moved after.

Sensor 2

Mis-Load: this sensor is positioned for shaped bar.

When loading shaped material into the collet section the bar has a tendency to catch

the rear of the collet/chuck due to it being bowed or buckled.

When setting this sensor: load the shortest bar that’s been cut, insert it into the collet

section then disconnect the air supply and manually push the Main Push rod behind

the back of the bar and feed to the rear of the collet/chuck.

Set the Mis-load sensor directly below the Pusher carriage so that the LED

aluminates on the sensor, secure the sensor at this position then re-connect the air

supply.

When Barfeed is in auto operation and reloading bar takes place the bar is checked

when feeding it through the collet/chuck, if the bar becomes jammed behind the

collet/chuck the Main Push rod will pulse up to eight times whilst the Spindle is

slightly rotating, this will encourage the bar to be fed through the collet/chuck.

If the bar is unable to feed through the collet/chuck after 8 attempts the Barfeed will

generate an alarm to the Lathe and stop pushing.

Loading...

Loading...