38

10.1 TROUBLE SHOOTING

Common causes and solutions for fault Diagnostics

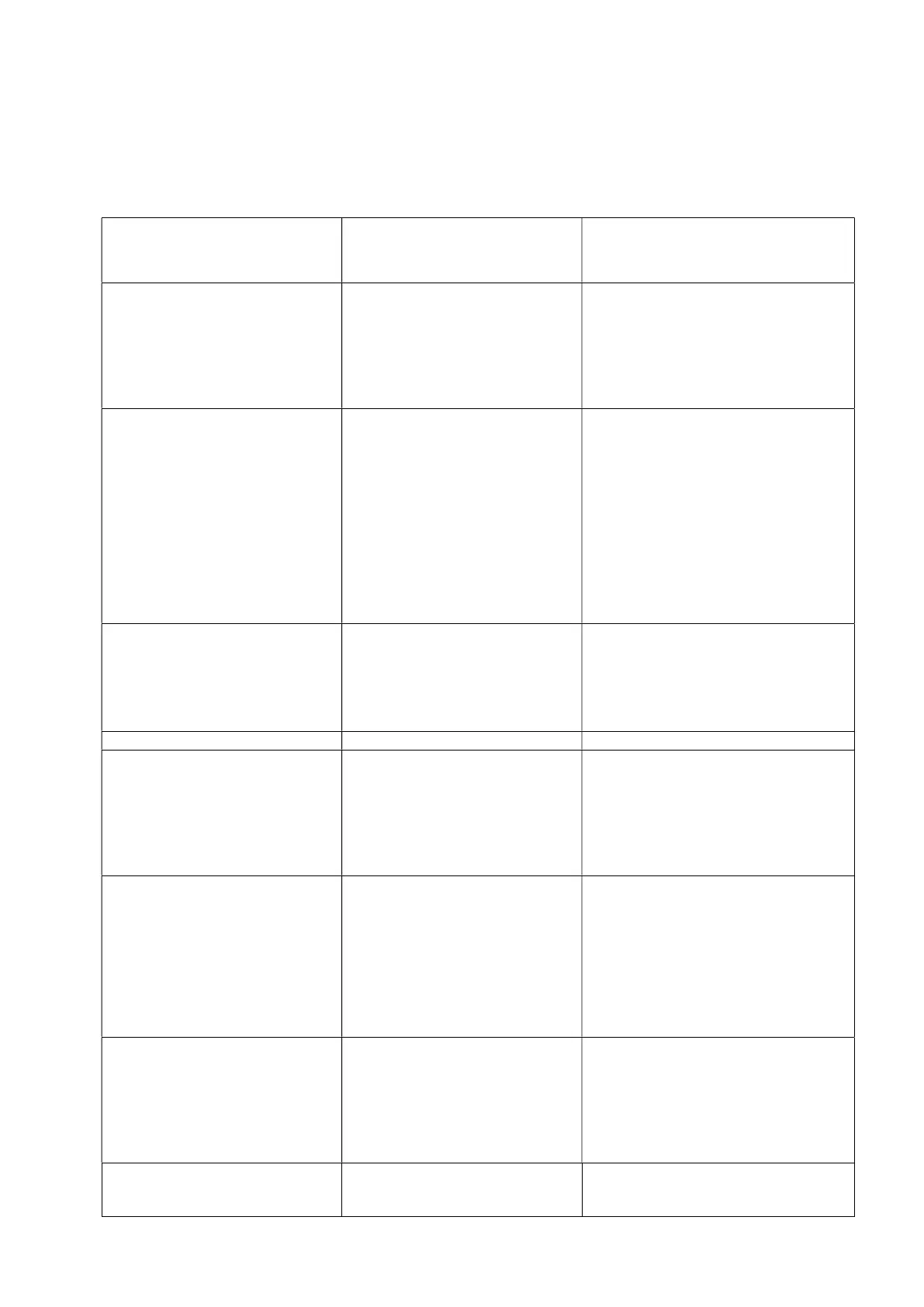

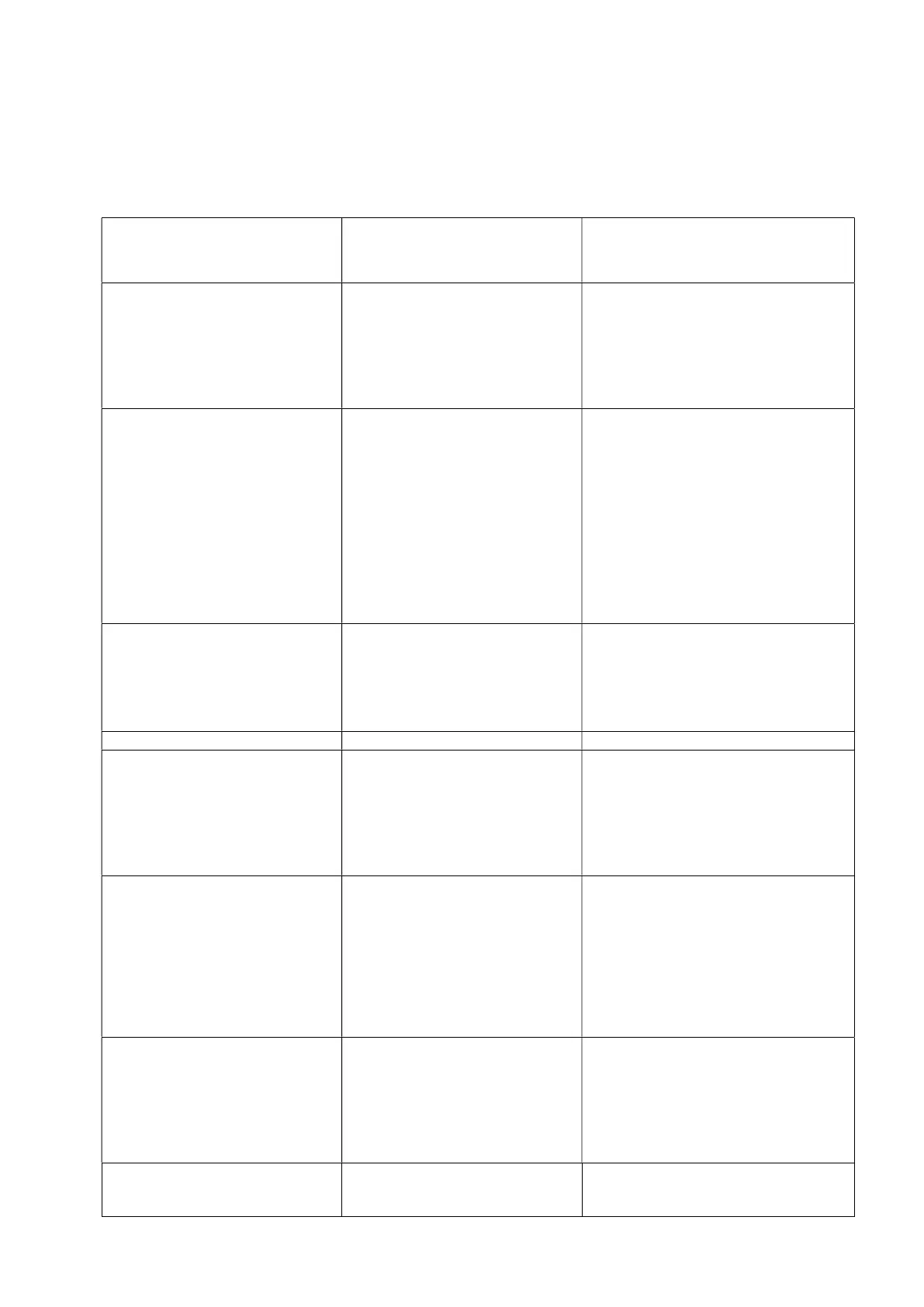

Problem; Category Cause of reaction Countermeasures; Action

Not Referencing 1.Air pressure too low!

2.EM.Stop not released on;

Barfeed of Lathe!

4.Man/Auto switch in Auto!

5.Home sensor not active!

Pressure 60psi and above.

Make application safe before

releasing EM.Stops

Switch to manual mode.

Check input X11 (sensor below

carriage)! Possible faulty sensor!!

Hand unit not responding 1.Main pusher; NO input X14!

2.Insert pusher; NO input X15!

3.Cross slide; NO input X15 or

X14!

4.Cam Control; NO input X14

and input X12 not registering!

Home sensor NOT active

Safety circuit NOT active

Check proximity related sensors.

Check location of X11 home sensor

must be aprox centre of carriage.

(test with magnet at close proximity)

Check safety circuit diagnostics!

Safety Circuit not ready 1.Lathe EM.Stop active!

2.Barfeed EM.Stop active!

3.Guarding not closed!

4.Low pressure!

Release EM.Stop.

Close all necessary guarding.

Increase pressure 60 psi and above.

Auto initiation 1.Auto not selected!

2.Lathe safety circuit not ready!

3.Lathe collet/chuck open!

4.LED’s flashing

Select auto mode

Secure Lathe doors, select

Barfeeding mode.

Close collet/chuck.

See alarm code messages.

Pusher not feeding 1.Auto not engaging.

2.No collet open signal! Check

input X17.

3.Lathe safety circuit not ready!

Check input X16.

4.Push command not active!

Check input X0.

Re-select auto.

Clamp collet/chuck to material.

Secure Lathe doors, select

Barfeeding mode.

Generate the feed request

command.

Pusher not retracting 1.Collet not closing!

2.Not retracting enough!

3.Check output Y3 on and

output Y2 off! (if this the case,

possible faulty valve).

Close the collet.

Increase the retract valve,) see page

14.

Possible valve replacement. Quote

serial number of Barfeed when

contacting us.

Pusher keeping forward on

Eject

Pusher not retracting passed

the EOB sensor after feeding

out last component.

Increase the retract valve,) see page

14.

Loading...

Loading...