83

Maintenance

3 main points that must be maintained at all times

- Good housekeeping maintained at all times.

- Be sure all work area around Multifeed is kept clear, anything that’s obstructive that

restricts the access to servicing Multifeed is removed.

- The main cylinder slide way must be free of greases and lubricants. Wipe clean

only.

Mulitfeed MX1B Front & Rear Loading Maintenance

IF IN DOUBT OF ANY OPERATION OR RISKS DETAILED BELOW, CONSULT

TRAINED OPERATOR OR CALL HYDRAFEED LTD AND STATE MODEL AND

SERIAL NUMBER OF UNIT. 01908 376331.

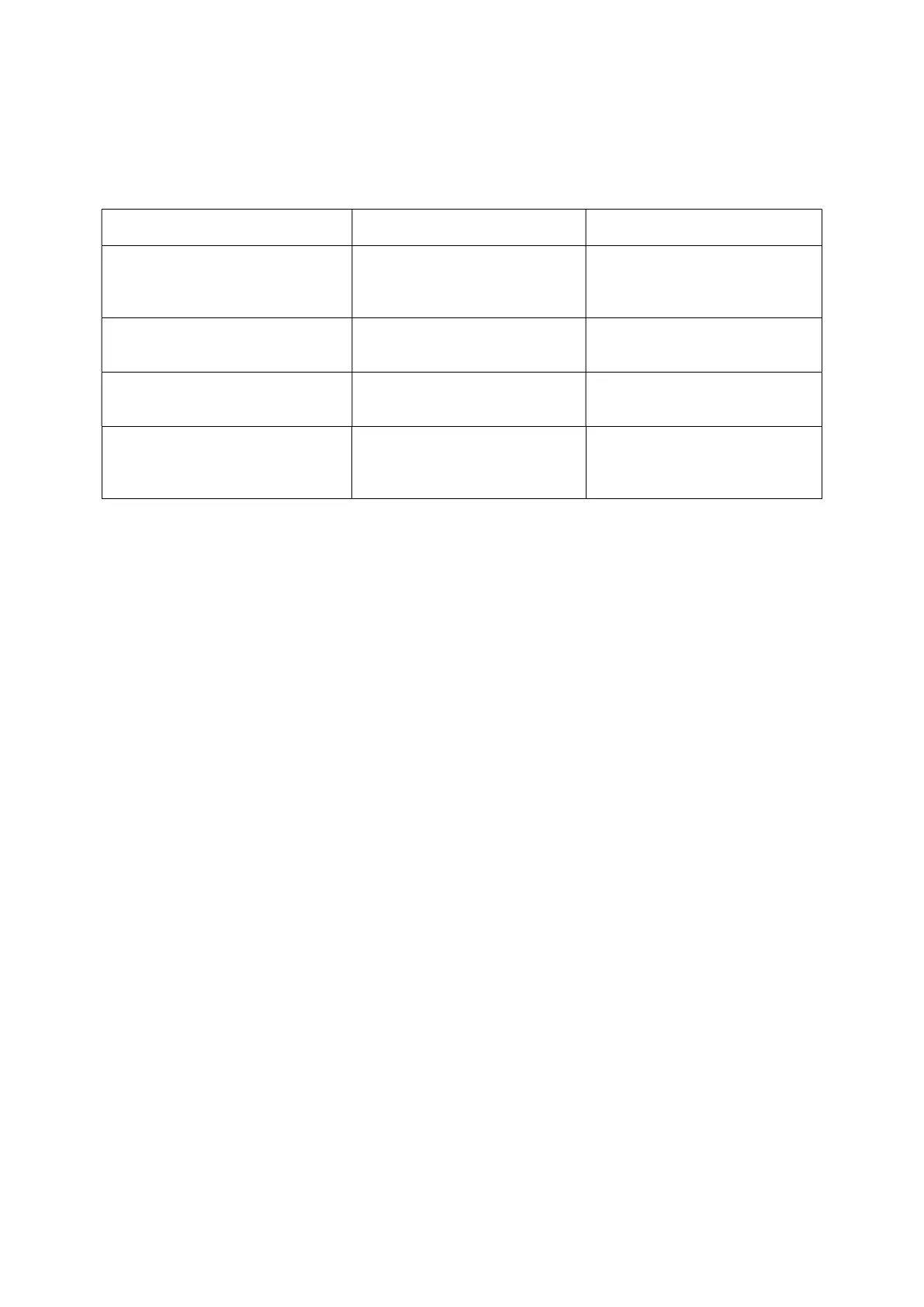

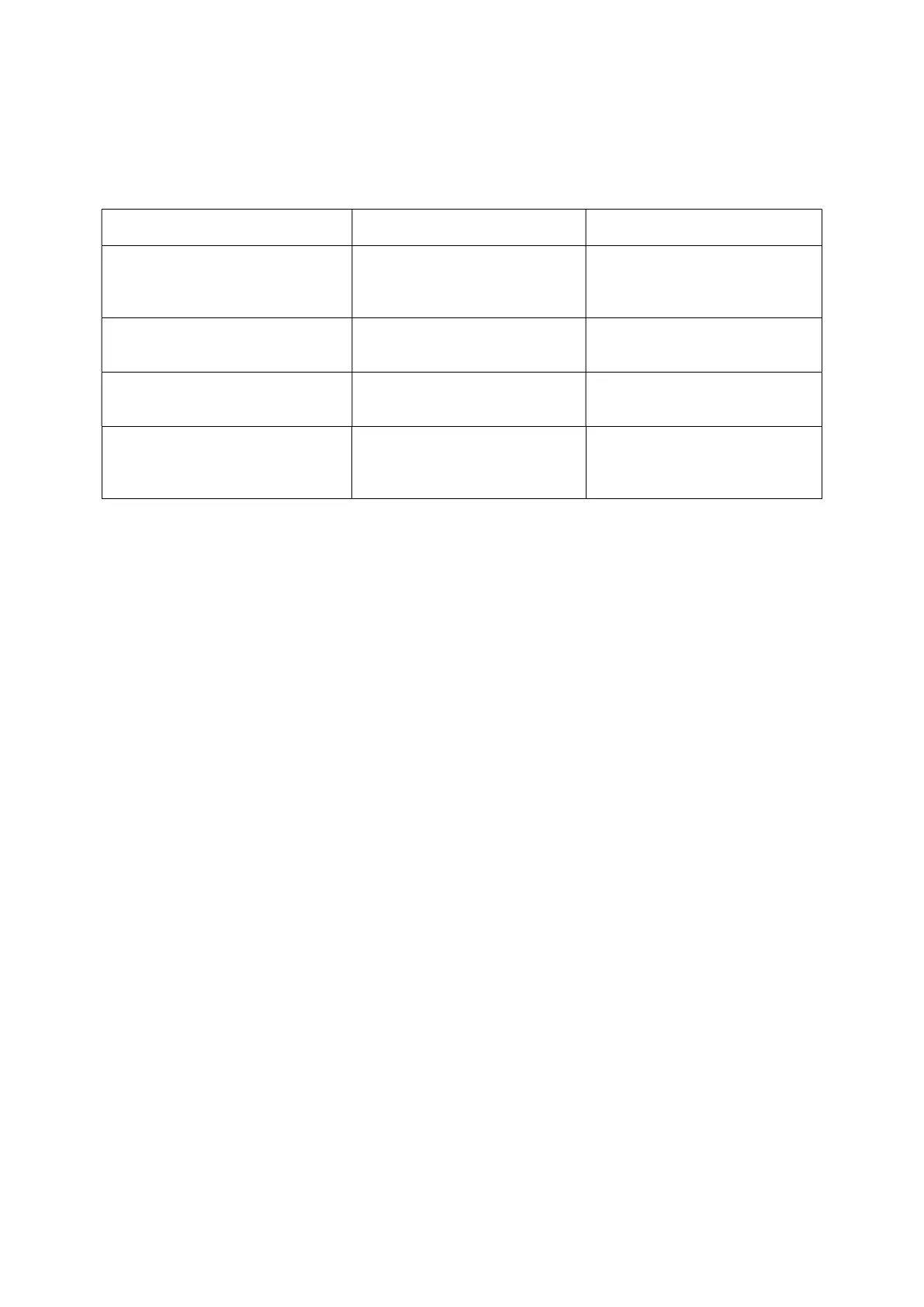

MAINTENANCE REQUIRED

HOW OFTEN & LOCATION

SYMPTOMS / COURSE OF

ACTION

Optical sensor clean

Every 2 weeks

X-tract magazine, Balluff sensor

BOS6KNU-7QC-S75-C – See

drawing page 25

If dirty optical beam detects and

incorrect readings given. Clean

both sensor and reflector.

Filter Regulator

Every 6 months

Base of barfeed side

Water trap to be unscrewed and

emptied, through air bleeder. page

33

Swarf & foreign object removal

General house keeping

Swarf can stop parts being

removed from spindle or rolling

down magazine.

Wear on push rod and push rod

bush

Once every 3 months

Oval shape of push rod bush,

out of alignment with spindle,

visual wear on steel push rod

and plastic bush, page 21

Loading...

Loading...