MAINTENANCE

HPR260 Manual Gas Instruction Manual 5-45

Automatic chopper and current sensor tests during power-up

Turn ON the system. When the preflow starts, the contactor will close and the system will

automatically test the choppers and current sensors. The system closes the contactor and turns

on chopper 1 at 90% duty cycle. The chopper will charge the surge capacitor on the I/O board

(PCB 6). The current that charges the capacitor should be between 10 amps and 35 amps.

Error code 105 will appear in the LED display if the current is < 10 amps or there is no

feedback on current sensor 1 (CS1). Error code 103 will appear in the LED display if the

current is > 35 amps.

If chopper 1 passes the test, the system will repeat the test for chopper 2, and current sensor 2

(CS2). Error code 106 will appear in the LED display if the current is < 10 amps. Error code

104 will appear in the LED display if the current is > 35 amps.

Place the toggle switch in the ERROR position if the system completes the power up

sequence. If the system shows error code 003 the test passed. The choppers and current

sensors are OK.

If error code number 103, 104, 105, or 106 are displayed, continue with the tests below.

Troubleshooting low-current error codes 105 and 106

1. Verify that the current sensors (CS1 and CS2) and

cables are not damaged.

2. Exchange CS1 and CS2. Replace the faulty sensor if

the error code is not displayed again.

3. Measure the resistance between wire 38 and wire 39

on PCB6 with a meter. The value should be increasing

as the capacitor charges. Replace PCB6 if a constant

value is seen.

4. Check for loose wires or shorts from the chopper to

PCB6.

5. Check for 220 VAC to 1A, 1B, and 1C on the chopper

when the contactor closes.

6. Verify that the fuses (F3 and F4) are in good working

condition.

Chopper tests

WARNING

SHOCK HAZARD: Use extreme care when working near the chopper modules. Each large electrolytic

capacitor (blue-cased cylinder) stores large amounts of energy in the form of electric voltage. Even if

the power is off, dangerous voltages exist at the capacitor terminals, on the chopper, and the diode

heatsinks. Never discharge any capacitor with a screwdriver or other implement … explosion,

property damage and/or personal injury will result.

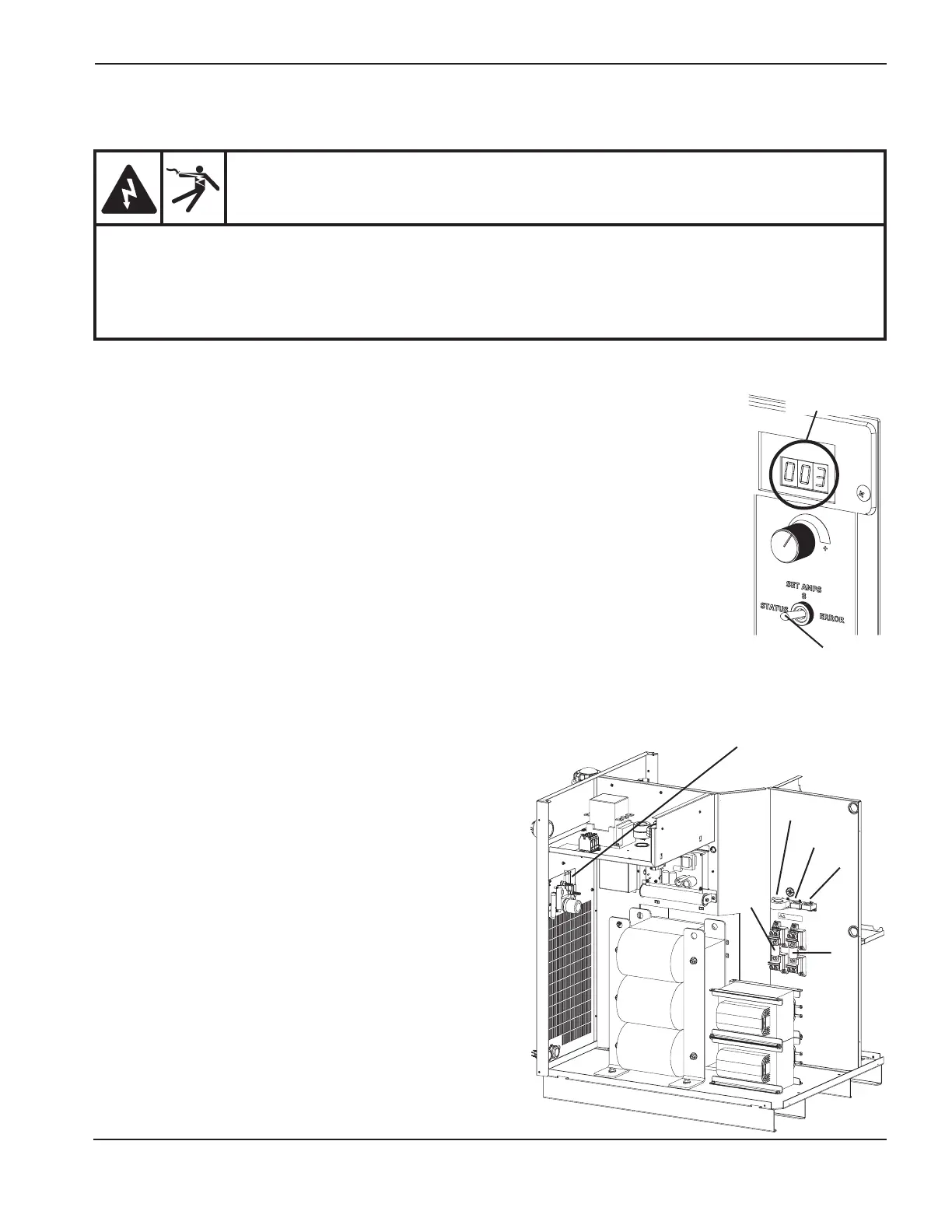

CS1

CS3

F3

I/O board

(PCB6)

CS2

F4

Toggle

switch

LED display

4

Loading...

Loading...