HyPrecision 50S/60S/75S Operator Manual 808690 117

5 – Preventive maintenance

Preventive maintenance

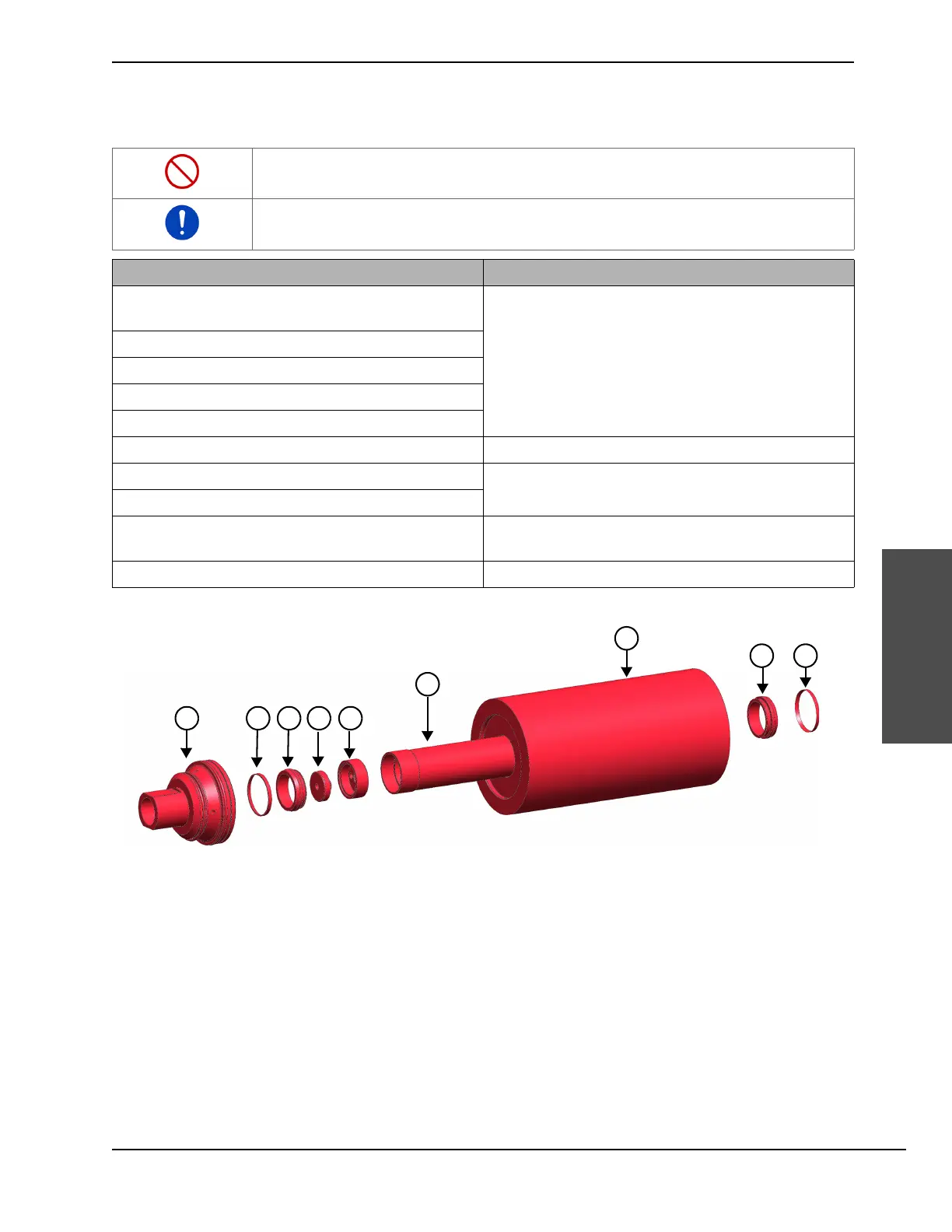

Install the high-pressure hoops, the high-pressure water seals, the high-pressure cylinders, and the

check valves

Do not put grease or lubricant on the check valve face or in the cylinder bore. These are designed

for dry contact.

Install a new plunger bearing when replacing the high-pressure cylinder.

Service Interval

Repair the check valves and the low-pressure poppets

(page 107)

After every 500 hours of operation

Repair the high-pressure cylinders (page 109)

Replace the check valve O-rings

Replace the high-pressure hoops

Replace the high-pressure water seals

Replace the low-pressure poppets After every 1,000 hours of operation

Replace the check valves

After every 2,000 hours of operation

Replace the low-pressure poppet baskets

Replace the high-pressure cylinders

After every 3,000 hours of operation or if the cylinder is

chipped or cracked

Replace the spacer tubes After every 12,000 hours of operation

1 Check valve

2 High-pressure hoops

3 High-pressure water seals

4 Low-pressure poppet

5 Low-pressure poppet basket

6 Spacer tube

7 High-pressure cylinder

Loading...

Loading...