OPERATION

0

powermax1250 Operator Manual 4-15

Cut charts

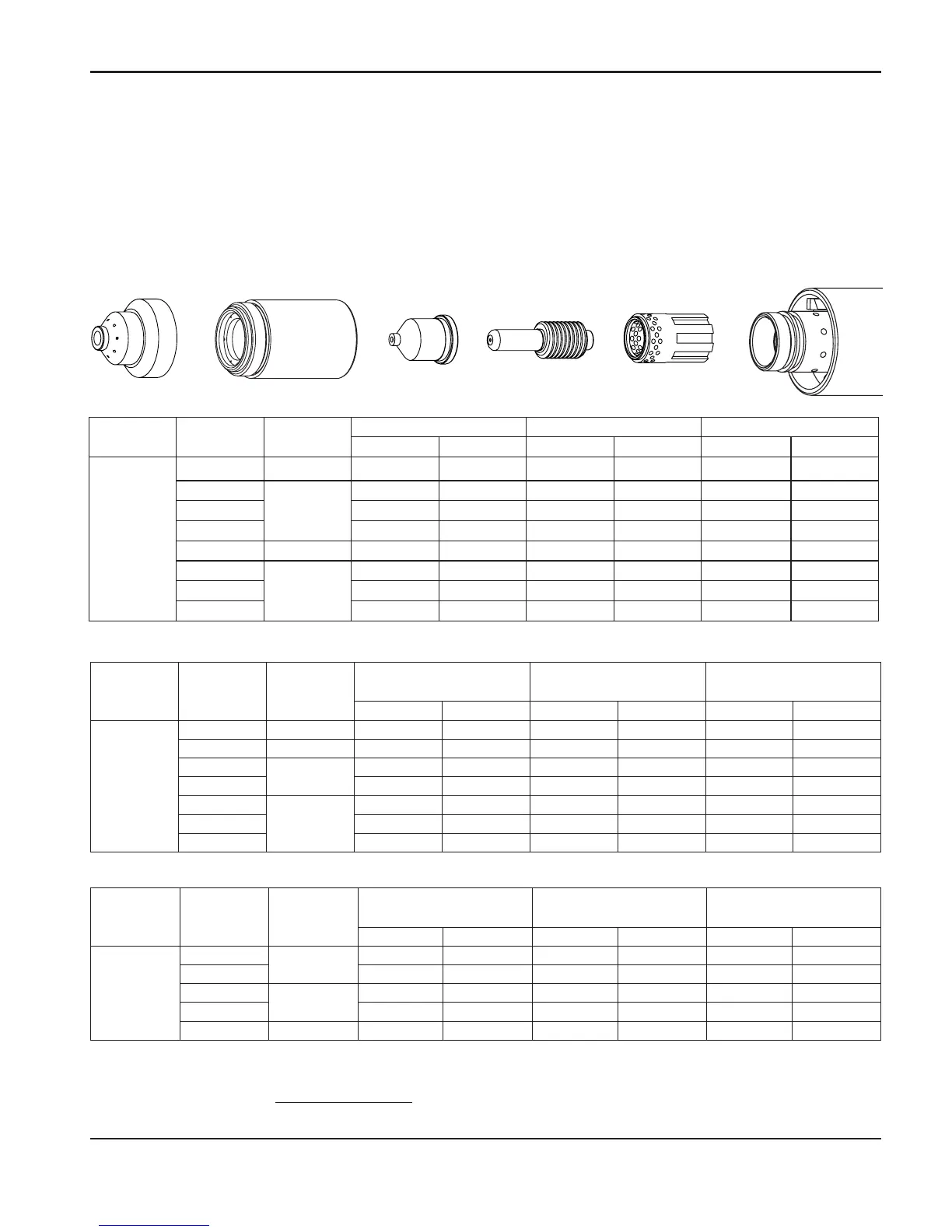

80 amp mechanized shielded consumables

• Torch-to-work distance for the following cut chart is 1/16 inch (1.5 mm) for all cuts.

Retaining cap

120928

Nozzle

120927

Electrode

120926

Swirl ring

120925

T80M

torch

Shield

120930

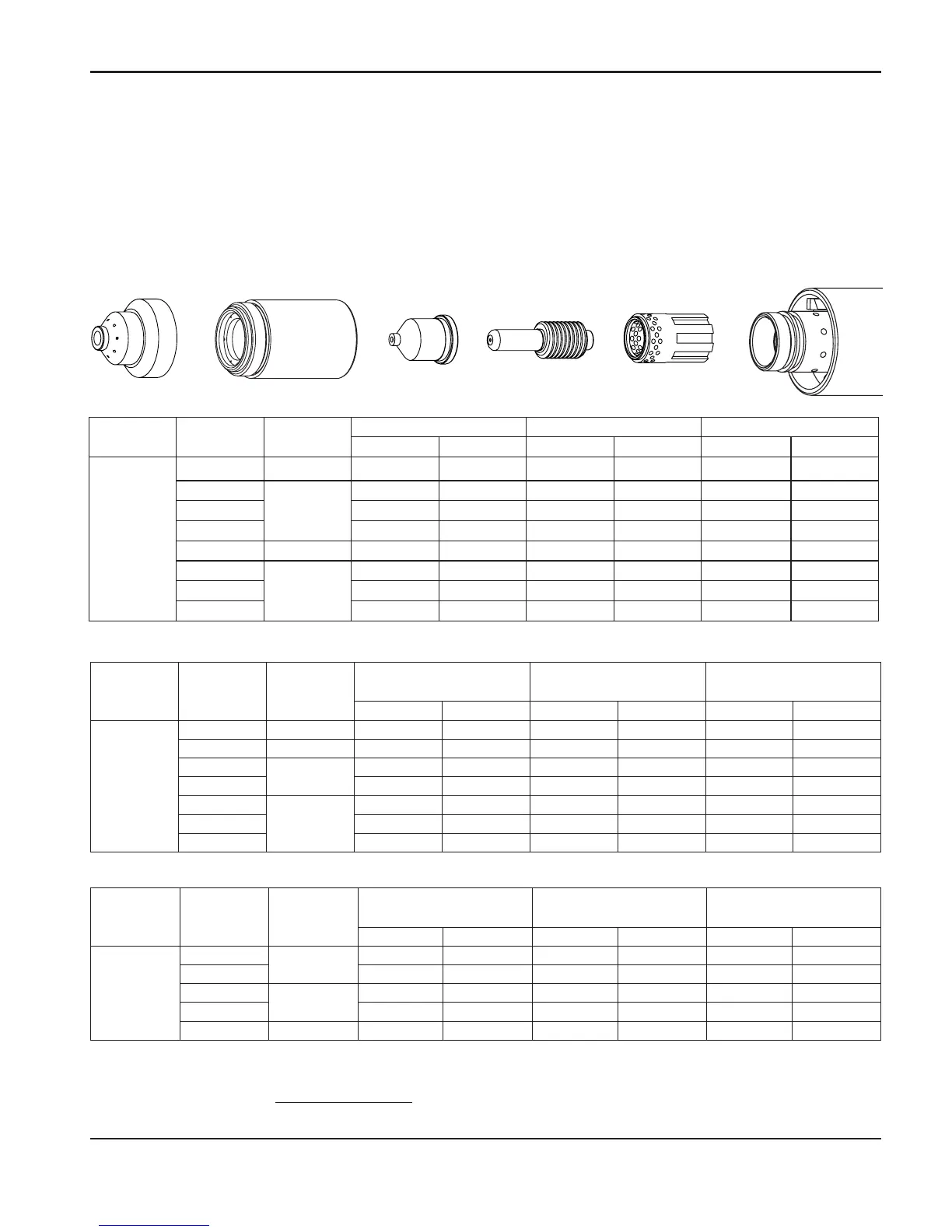

Maximum travel speeds are the fastest travel speeds possible to cut the material without regard to cut quality.

Optimum travel speeds provide the best cut angle, least dross and best cut surface finish. Remember that cut charts

are intended to provide a good starting point for each different cut assignment. Every cutting system requires

“fine tuning” for each cutting application in order to obtain the desired cut quality.

Mild steel

Stainless steel

Aluminum

Arc

current

Arc

voltage

Pierce

delay

Material thickness

Maximum travel speeds Optimum travel speeds

inches mm

ipm mm/min ipm mm/min

80

134 0.25

3/16" 4.8

216 5486 140 3556

136 0.50

1/4" 6.4

158 4013 103 2616

139

0.75

3/8" 9.5

83 2108 54 1372

142

1/2" 12.7

50 1270 33 838

145

NA

5/8" 15.9

34 864 22 559

150

3/4" 19.0

24 610 16 406

153

1" 25.4

14 356 9 229

Arc

current

Arc

voltage

Pierce

delay

Material thickness

Maximum travel speeds Optimum travel speeds

inches mm

ipm mm/min ipm mm/min

80

134

0.25

1/8" 3.2

454 11532 295 7493

139

1/4" 6.4

176 4470 114 2896

143

0.75

3/8" 9.5

121 3073 60 1524

146

1/2" 12.7

75 1905 37 940

154 NA

3/4" 19.0

37 940 19 483

Arc current

Arc

voltage

Pierce

delay

Material thickness

Maximum travel speeds Optimum travel speeds

Inches mm

ipm mm/min ipm mm/min

80

132 0.25

3/16" 4.8

216 5486 140 3556

134

0.50

1/4" 6.4

161 4089 105 2667

137

3/8" 9.5

94 2388 61 1549

140

1/2" 12.7

60 1524 39 991

145 1.00

5/8" 15.9

40 1016 26 660

148

N/A

3/4" 19.0

31 787 20 508

150

7/8" 22.2

23 584 15 381

156

1" 25.4

16 406 10 254

Loading...

Loading...