OPERATION

0

powermax1250 Operator Manual 4-19

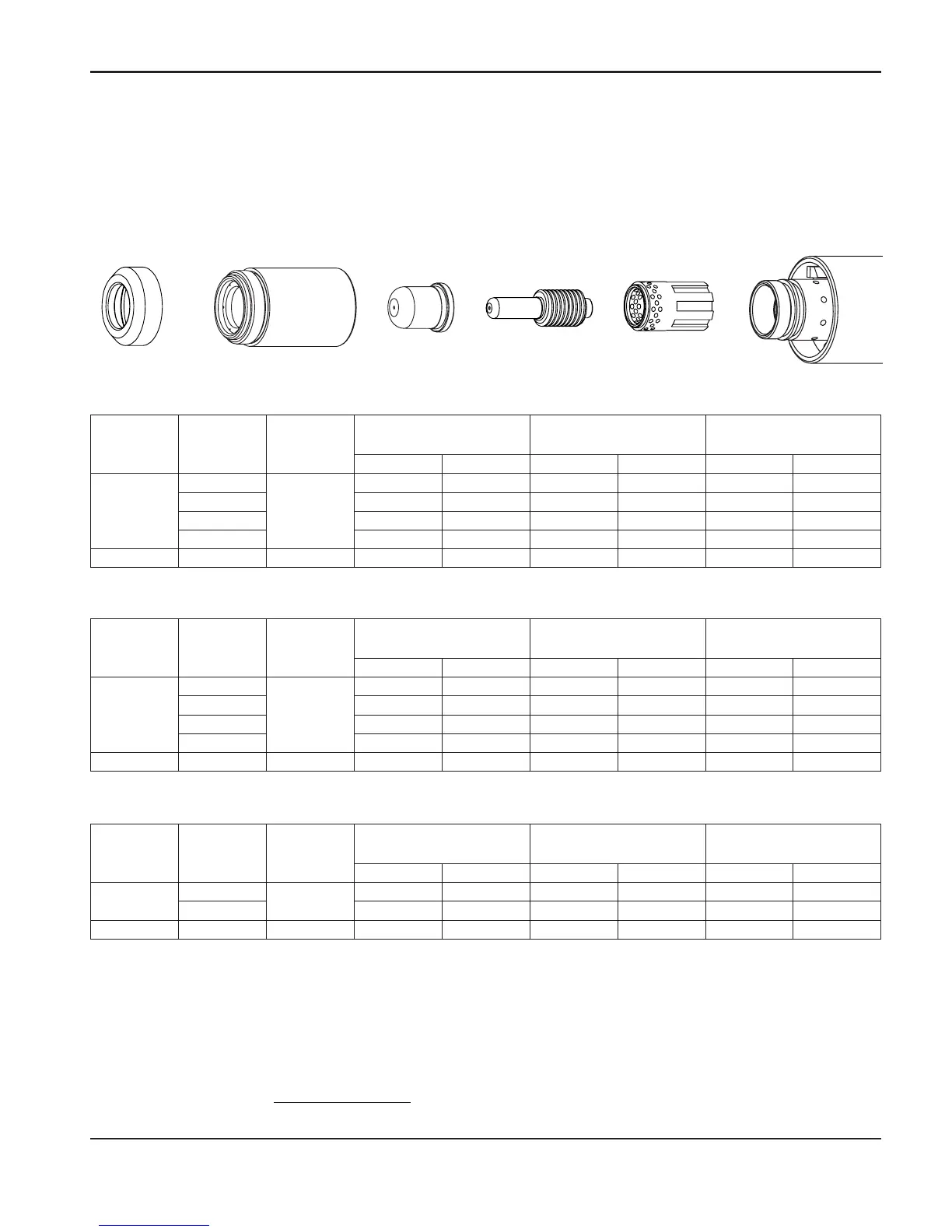

40 amp mechanized unshielded consumables

• Torch-to-work distance for the following cut chart is 1/16 inch (1.5 mm) for all cuts.

Retaining cap

120928

Nozzle

220006

Electrode

120926

Swirl ring

120925

T80M

torch

Deflector

120979

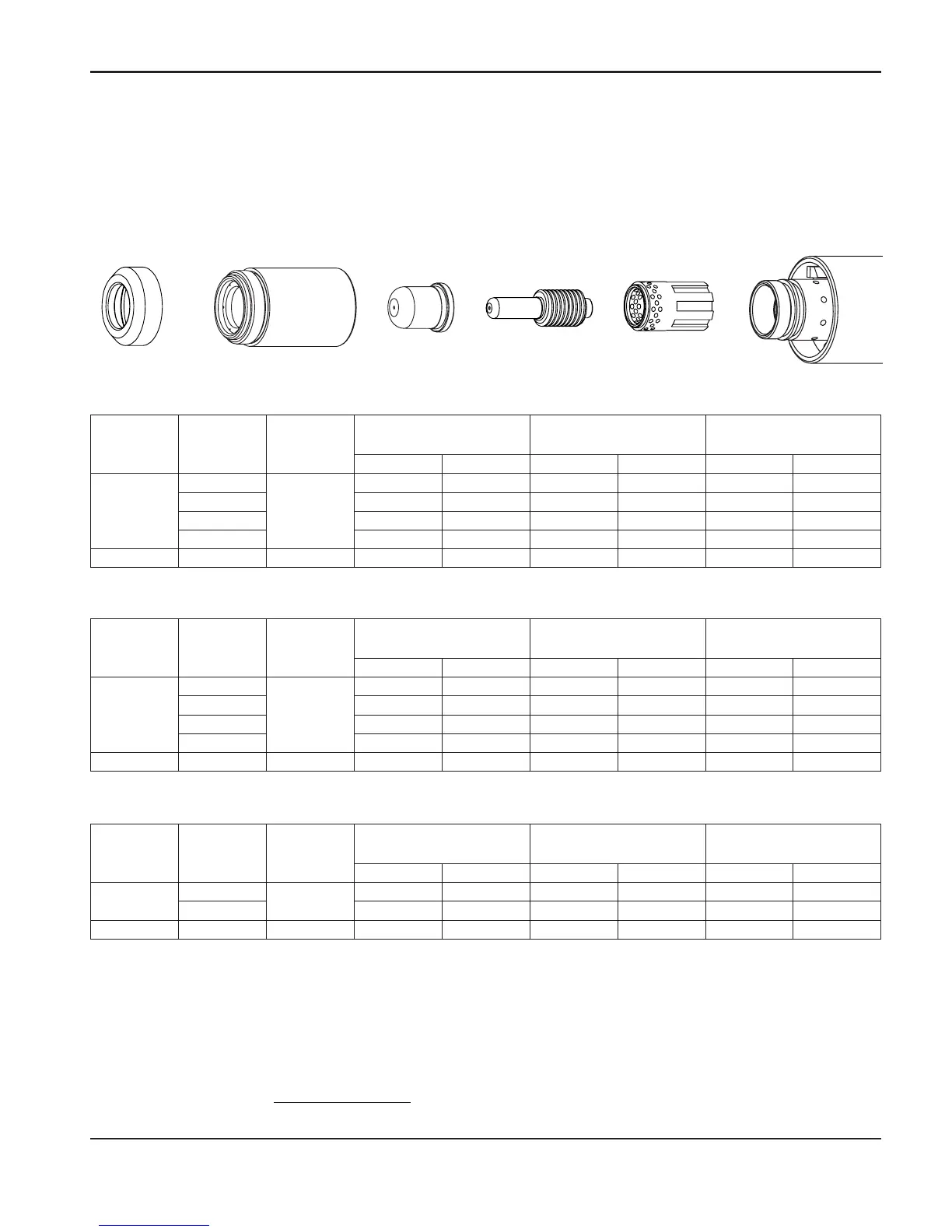

Maximum travel speeds are the fastest travel speeds possible to cut the material without regard to cut quality.

Optimum travel speeds provide the best cut angle, least dross and best cut surface finish. Remember that cut charts

are intended to provide a good starting point for each different cut assignment. Every cutting system requires

“fine tuning” for each cutting application in order to obtain the desired cut quality.

Mild steel

Stainless steel

Aluminum

Arc

current

Arc

voltage

Pierce

delay

Material thickness

Maximum travel speeds Optimum travel speeds

inches mm

ipm mm/min ipm mm/min

25

125

0

26 ga 0.5

550 13970 353 8966

128

22 ga 0.8

484 12294 315 8001

130

18 ga 1.3

238 6045 155 3937

131

16 ga 1.5

167 4242 109 2769

40 129 0.25

14 ga 1.9

326 8280 212 5385

Arc

current

Arc

voltage

Pierce

delay

Material thickness

Maximum travel speeds Optimum travel speeds

inches mm

ipm mm/min ipm mm/min

25

127

0

26 ga 0.5

561 14249 365 9271

127

22 ga 0.8

453 11506 295 7493

123

18 ga 1.3

500 12700 325 8255

127

16 ga 1.5

367 9322 239 6071

40 128 0.25

14 ga 1.9

220 5588 143 3632

Arc

current

Arc

voltage

Pierce

delay

Material thickness

Maximum travel speeds Optimum travel speeds

inches mm

ipm mm/min ipm mm/min

25

125

0

1/32 0.8

564 14326 366 9296

127

1/16 1.5

236 5994 153 3886

40 127 0.25

3/32 2.4

261 6629 170 4318

Loading...

Loading...