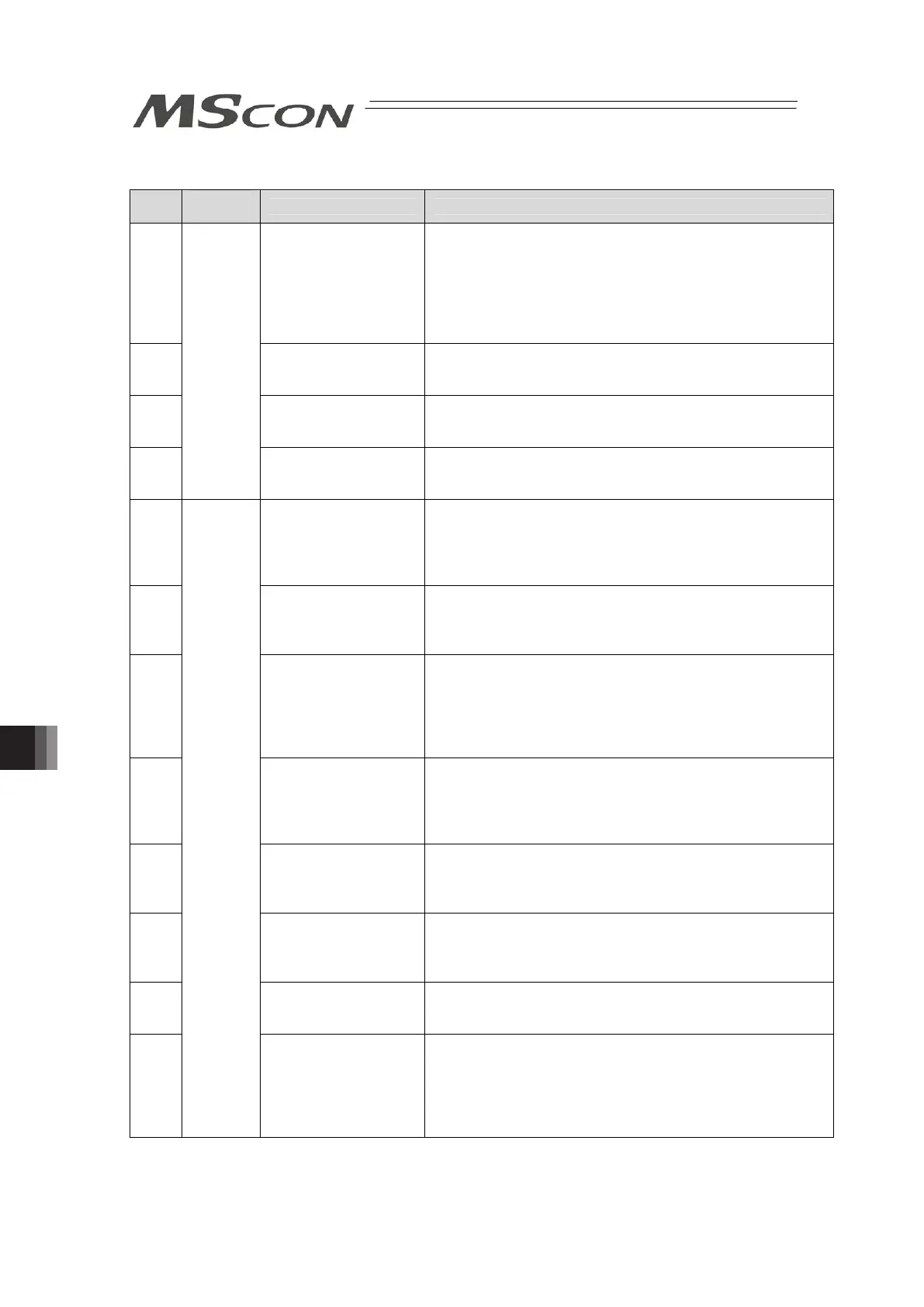

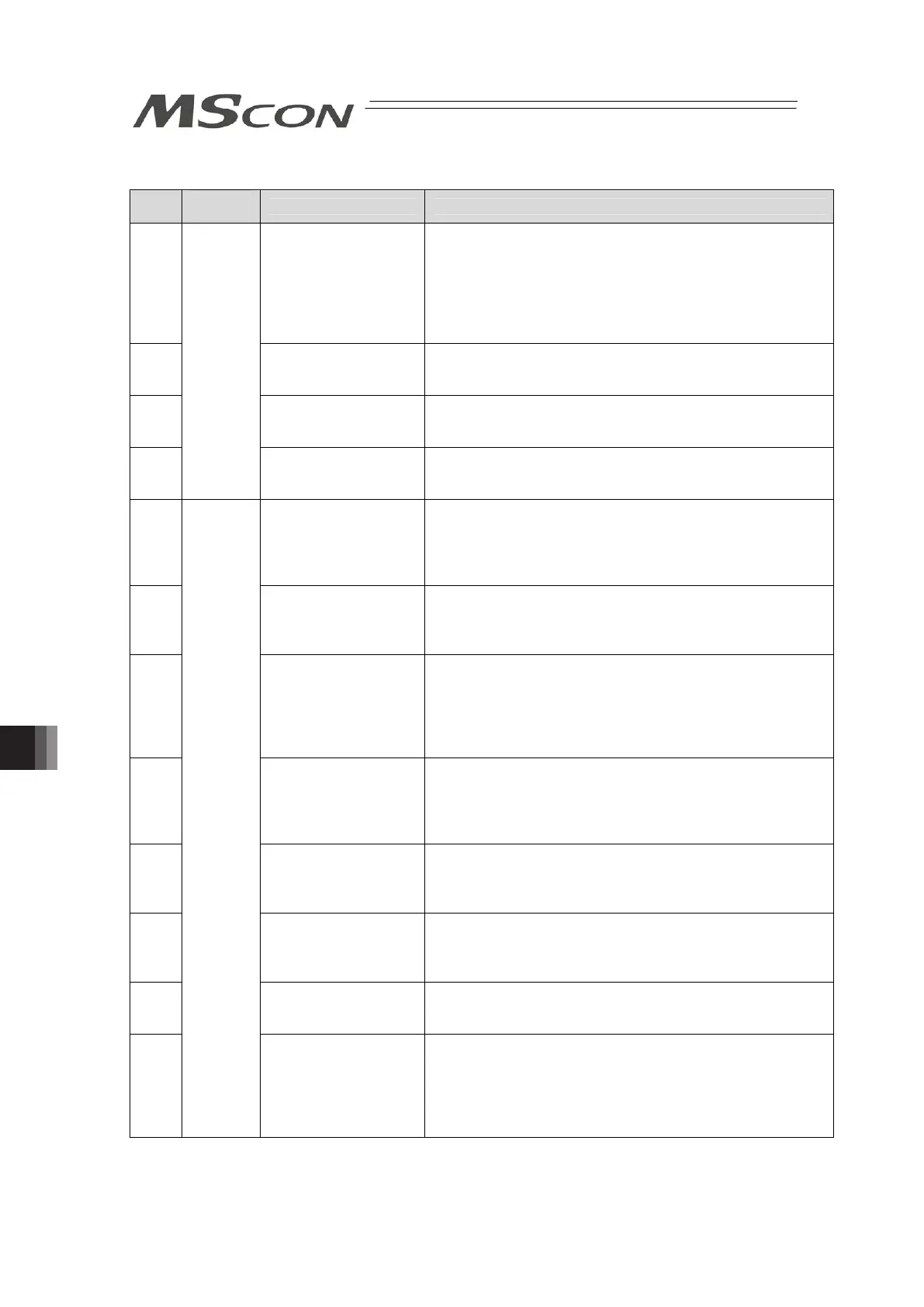

Chapter 8 Troubleshooting

292

[3] Alarm List

Alarm

Code

Alarm

Level

Alarm Name Cause/Treatment

048 Driver overload alarm

Cause : The load current exceeded the value set in

Parameter No.143 “Overload Level Ratio”.

This alarm is kept alarm condition until reset is

made. This alarm turns ON when the load current

exceeds the setting from a value below the setting.

Treatment : Lower the setting of acceleration/deceleration.

Also, increase the frequency of pause.

04E Exceeded movement

count threshold

Cause : The total number of the operation times exceeded

the value set in Parameter No.147 “Total

Movement Count Threshold”.

04F Exceeded operated

distance threshold

Cause : The total number of the operation distance

exceeded the value set in Parameter No.148 “Total

Operated Distance Threshold”.

06B

Message

Maintenance

information data error

Cause : The maintenance information (total movement

count, total operated distance) is lost.

Treatment : Please contact IAI.

080 Move command in

servo OFF

Cause : A move command was issued when the servo is

OFF.

Treatment : Issue a movement command after confirming the

servo is ON (servo ON signal SV or position

complete signal PEND is ON).

082 Position Command in

incomplete home return

Cause : A position move command was issued before

home return was completed.

Treatment : Issue a command after confirming that home

return has been completed HEND is ON.

083 Numerical command in

incomplete home return

Cause : An absolute position command was issued by

numerical specification before home return was

completed (direct command from Field Network).

Treatment : Issue a numeric specification after performing

home return operation and confirming the

complete signal HEND.

084 Movement command

during home return

operation

Cause : A move command was issued when home return

was still in progress.

Treatment : Issue a movement command after performing

home return operation and confirming the

complete signal HEND.

085 Position No. error

during movement

Cause : A non-existing (invalid) position number was

specified in the positioner mode.

Treatment : Check the position table again and indicate an

effective position number.

090 Software reset during

servo ON

Cause : A software reset command was issued when the

servo was ON.

Treatment : Issue a software reset command after confirming

that the servo is OFF (SV signal is 0).

091 Position No. error in

teaching

Cause : The position number out of the available range

was selected in the teaching.

Treatment : Select the position number from 63 or smaller.

092

Operation

release

PWRT signal detection

during movement

Cause : The current position write signal PWRT was input

in the teaching mode of PIO pattern 1 while the

actuator was jogging.

Treatment : Input the PWRT signal after confirming that the job

button is not pressed and the actuator is stopped

(MOVE output signal is OFF).

Loading...

Loading...