2. ACON, PCON

38

2.6.5 Full Direct Value Mode (Number of Occupied Bytes: 32)

This is the operation mode with all the values (target position, speed, etc.) set up directly using values from

PLC. Set each value in the I/O area.

The robot cylinder's effective main functions that can be controlled using this mode, are as shown in the

following table.

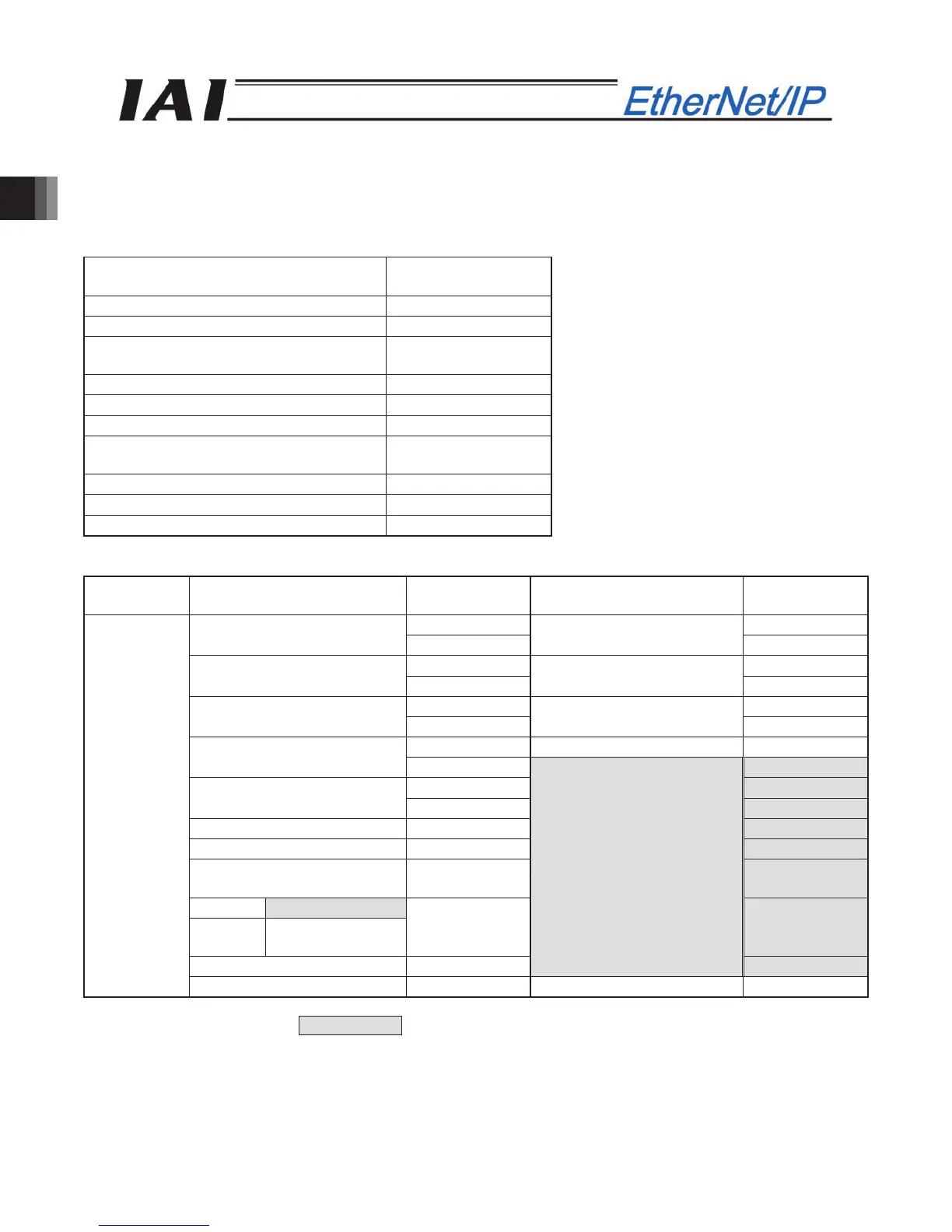

ROBO cylinder function

{: Direct control

x: Disable

Home-return operation

{

Positioning operation

{

Speed and acceleration / deceleration

setting

{

Pitch feed (inching)

{

Pressing operation

{

Speed change during the movement

{

Operation at different acceleration and

deceleration

{

Pause

{

Zone signal output

{

PIO pattern selection x

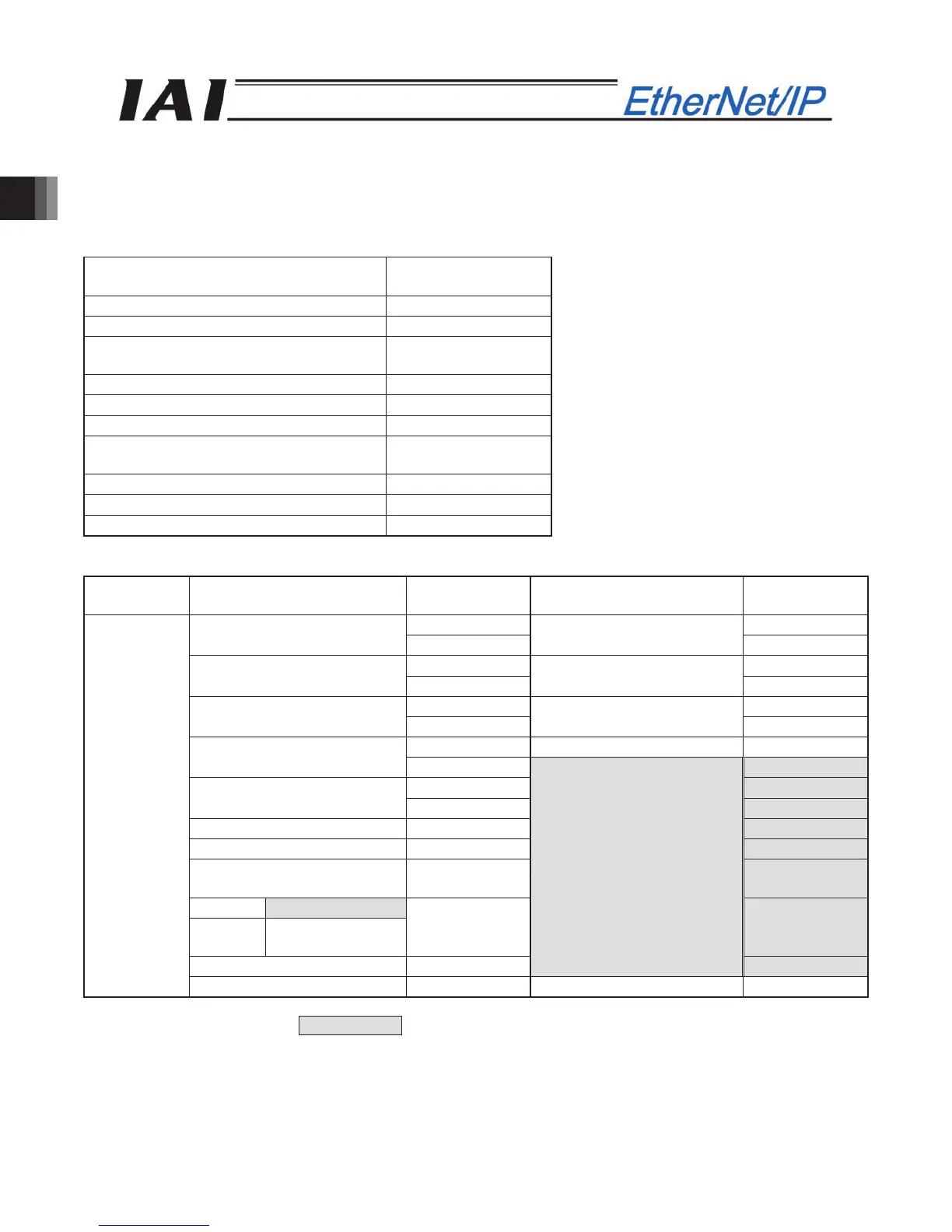

(1) PLC address configuration (* "n" indicates the first address of each axis.)

Parameter

No.84

ACON/PCON input register

PLC output

address (bytes)

ACON/PCON output register

PLC input

address (bytes)

n, n+1 n, n+1

Target position

n+2, n+3

Current position

n+2, n+3

n+4, n+5 n+4, n+5

Positioning band

n+6, n+7

Command current

n+6, n+7

n+8, n+9 n+8, n+9

Speed

n+10, n+11

Current speed

n+10, n+11

n+12, n+13 Alarm code n+12, n+13

Zone boundary +

n+14, n+15

n+14, n+15

n+16, n+17 n+16, n+17

Zone boundary -

n+18, n+19

n+18, n+19

Acceleration n+20, n+21 n+20, n+21

Deceleration n+22, n+23 n+22, n+23

Pressing current-limiting

value

n+24, n+25

n+24, n+25

ACON Occupied area

PCON

Load current

threshold

n+26, n+27

n+26, n+27

Control signal 1 n+28, n+29

Occupied area

n+28, n+29

3

Control signal 2 n+30, n+31 Status signal n+30, n+31

(Note) The areas denoted by Occupied area cannot be used for any other purpose.

Also, exercise caution to avoid node address duplication.

Loading...

Loading...