11

SEALED SYSTEM REQUIREMENTS

Working pressure 6 bar maximum.

Particular reference should be made to BS. 6644 and Guidance

note PM5 "Automatically controlled steam and hot water boilers"

published by the Health and Safety Executive.

The information and guidance given below is not intended to

override any requirements of either of the above publications or

the requirements of the local authority, gas or water undertakings

.

In general commercial closed pressurised systems are provided

with either manual or automatic water make up.

In both instances it will be necessary to t automatic controls

intended to protect the boiler, circulating system and ancillary

equipment by shutting down the boiler plant if a potentially

hazardous situation should arise.

Examples of such situations are low water level and operating pressure

or excessive pressure within the system. Depending on circumstances,

controls will need to be either manual or automatic reset. In the event

of a shutdown both visual and audible alarms may be necessary.

Expansion vessels used must comply with EN 13831 and must be sized

on the basis of the total system volume and initial charge pressure.

Initial minimum charge pressure should not be less than

1.0 bar (14.7psi) and must take account of the static head and

specication of the pressurising equipment. The maximum

water temperatures permissible at the point of minimum

pressure in the system are specied in Guidance Note PM5.

When make up water is not provided automatically it will be

necessary to t controls which shut down the plant in the event

of the maximum system pressure approaching to within 0.35bar

(5psi) of the safety valve setting.

Other British Standards applicable to commercial sealed

systems are:

BS. 6880: Part 2 BS. 1212 BS. 6281: Part 1

BS. 6282: Part 1 BS. 6283: Part 4

12

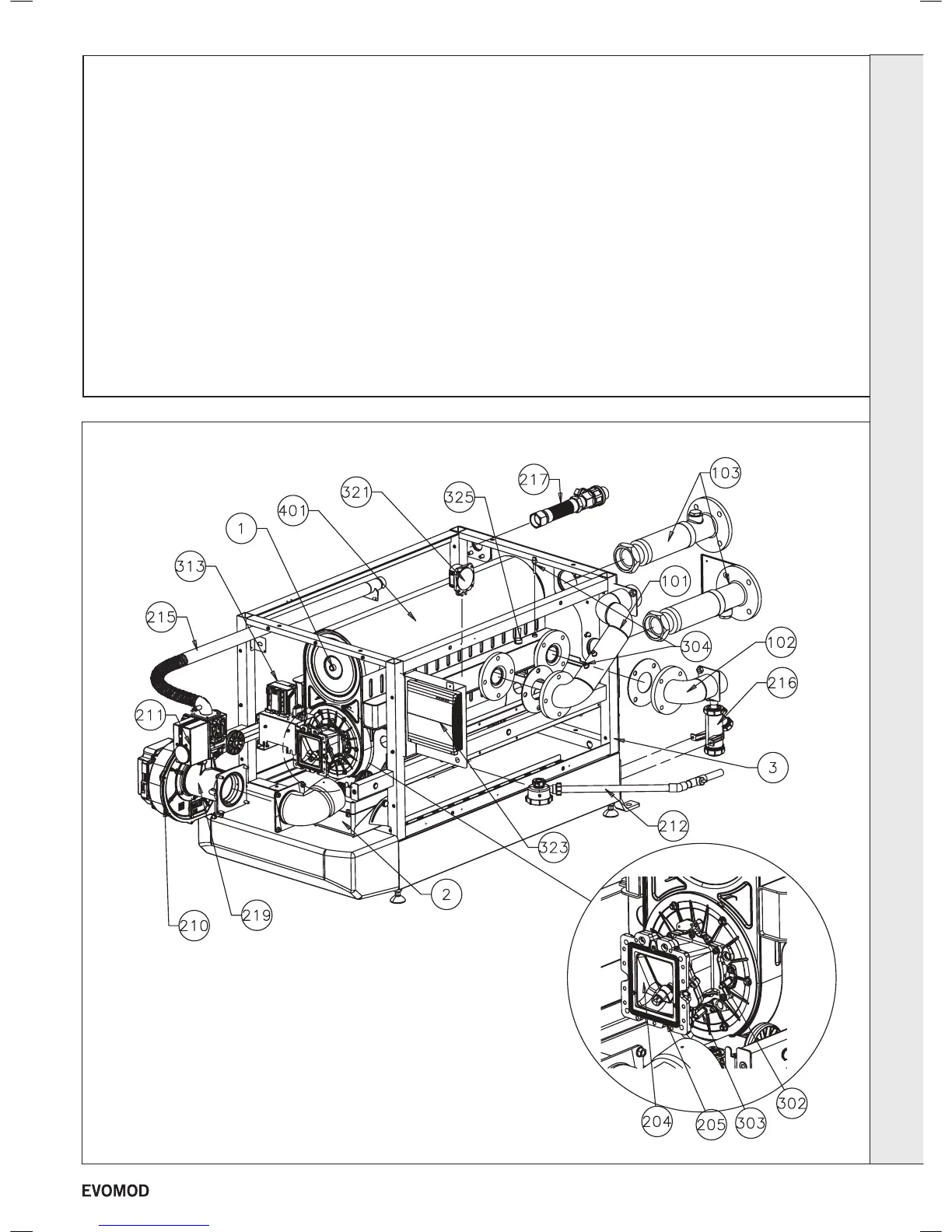

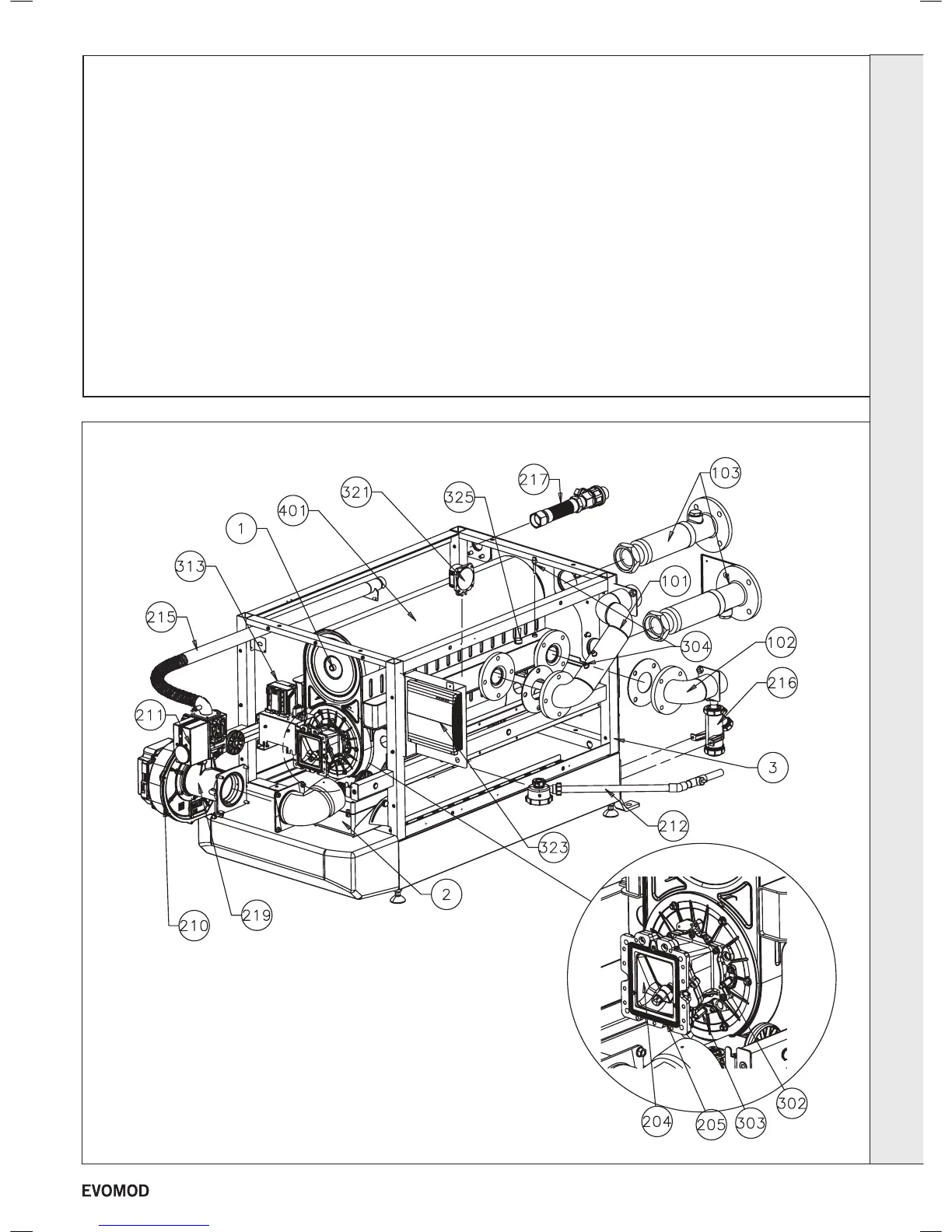

BOILER ASSEMBLY

Legend

INSTALLATION

1. Flue Sampling Point

2. Mains Connection Box

3. Earth Bonding Point

101. Flow pipe

102. Return Pipe

103. Hose Flexible 2

1

/2"

204. Flap Flange Unit

205. Flange Gasket

210. Fan

211. Gas Valve

212. Condensate Assy.

215. Gas Pipe

216. Condensate Trap

217. Gas Pipe Flexible 1

1

/4"

219. Venturi

302. Ignition Electrode

303. Detection Electrode

304. Thermistor (Flow)

304. Thermistor (Return)

313. Module PCB

321. Condensate Blockage

Pressure Switch

323. Master PCB box

325. Water Pressure Switch

401. Heat Exchanger

15

- Installation & Servicing

Loading...

Loading...