FOUNDATION / LOCATION OF BOILER

The boiler must stand on a oor which must be at, level and of a

suitable load bearing capacity to support the weight of the boiler

(when lled with water) and any ancillary equipment.

Ideally the boiler should be placed on a plinth exceeding the plan

area of the boiler by 75mm on each side and at least 100mm

high.

The boiler must not be tted outside.

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

A gas meter can only be connected by the local gas supplier or by

a Gas Safe Registered Engineer or in IE by a competent person.

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the

dynamic rate of gas supply required. A minimum working gas

pressure of 17mbar MUST be available at the boiler inlet for

Natural gas.

Do not use pipes of smaller size than the boiler inlet gas

connection.

The complete installation MUST be tested for gas soundness and

purged in accordance with the appropriate standards.

Gas Boosters

A gas booster is required if the gas pressure available at the boiler

is lower than that required by the boiler manufacturer to attain the

ow rate for maximum burner input rating.

Location of the booster requires careful consideration but

should preferably be closer to the burner rather than the gas

meter. Ventilation should also be considered to ensure ambient

temperature do not exceed designed recommendations. Further

guidance is provided in IGE/UP/2.

FLUE INSTALLATION

The ue header for 500-1000 boilers is supplied.

IMPORTANT. It is the responsibility of the installer to ensure,

in practice, that products of combustion discharging from the

terminal cannot re-enter the building or any other adjacent

building through ventilators, windows, doors, other sources of

natural air inltration, or forced ventilation / air conditioning.

If this should occur the appliance MUST be isolated from the

gas supply and labelled as 'unsafe' until corrective action can be

taken.

Terminal Position

Due to the high efciency of the boilers pluming will occur.

Particular care should be taken in the case of large output boiler

installations, and complying with the requirements of the Clean Air

Act.

The ue must be installed in accordance with the appropriate

Building Regulations and standards listed on page 4 and in

compliance with BS6644. In IE refer to I.S.820:2000.

FLUE SYSTEM DESIGN

Due to the high efciency of these boilers, the ue gas

temperatures are low and the buoyancy in the stack will be

relatively small. The boiler is supplied with an integral fan which

is fully matched to the boiler in each case to provide correct

combustion air ow and overcome the ue resistance.

The power of this fan is such that there is a large reserve of

pressure available to overcome a signicant length of ue without

affecting the combustion performance of the boiler.

The maximum pressure available at the base of the ue to

overcome ue resistance is 105Pa. This includes the resistance

of any air ducts used to connect the air inlet direct to outside air.

Care should be taken with tall ue systems to ensure excess

buoyancy is not created. A negative pressure must not be created

at the boiler ue outlet.

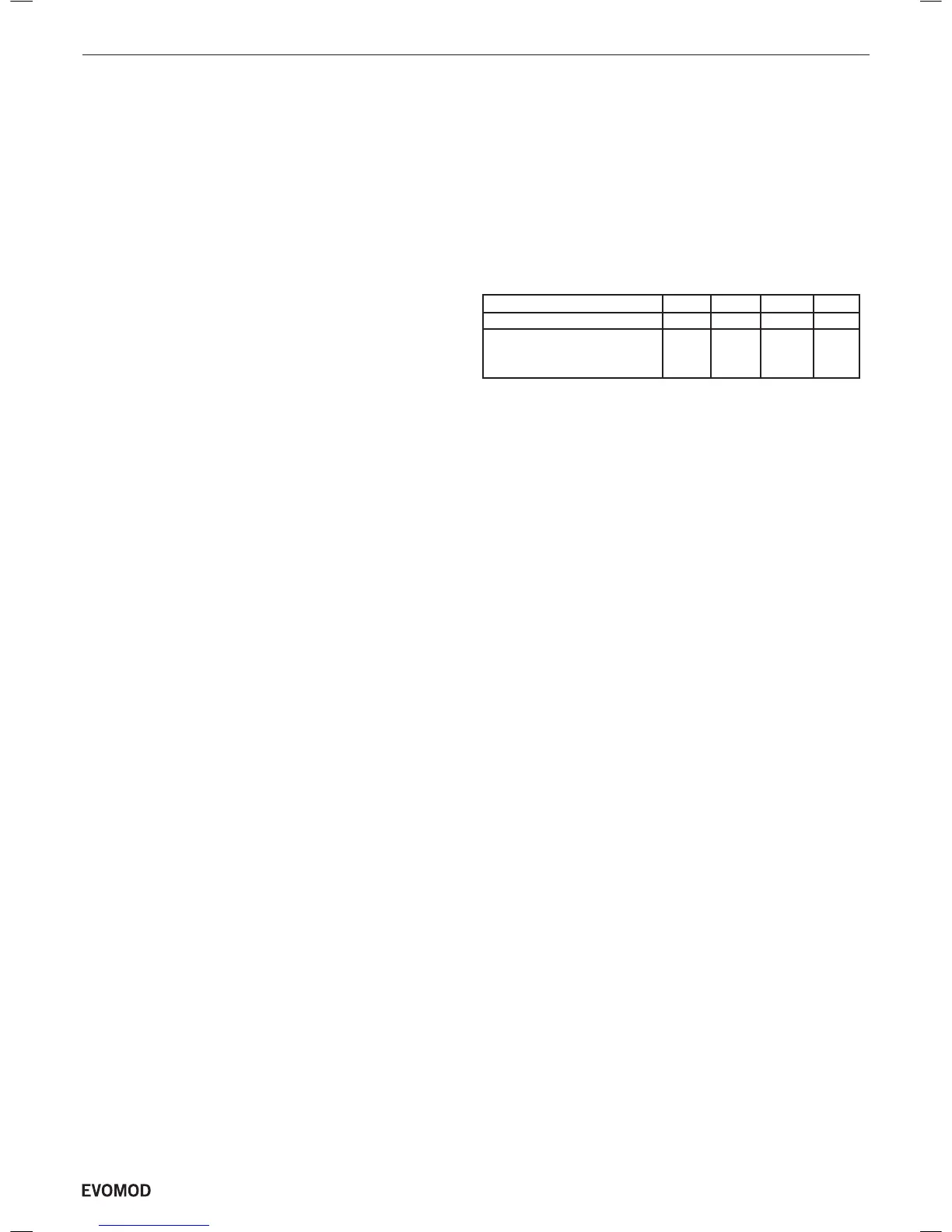

See table below for approximate maximum straight ue length.

Boiler 250 500 750 1000

Flue Size (mm) Ø150 Ø250 Ø250 Ø300

Approx. max.

Straight Flue 28 80 32 56

Length (m)

The addition of elbows and their positions in the ue will have

a signicant effect on the maximum allowable ue and air duct

lengths. Consult with your ue supplier for detailed design work.

IMPORTANT NOTE.

If combustion air is drawn from within the boiler room,

ensure no dust or airborne debris can be ingested into the

appliance. Dusty concrete ooring should be sealed to

reduce the presence of dust. Ideally where possible duct the

air supply into the boiler room from a clean source outside

the boiler room / building.

Material

With no requirement for buoyancy to discharge ue products

and with low ue gas temperatures, single wall ues are suitable

for most installations. Care should still be taken to maintain

compliance with building regulations and relevant standards.

The ue used should be a suitably approved ue for use on a

pressurised condensing ue system. The boiler is not suitable for

use on plastic ue systems.

Condensate produced in the ue should be drained

seperately before entering the boiler. A Drain point at the

bottom of the ue header (500, 750 and 1,000) is provided for this

purpose.

Advice regarding the availability of proprietary types of ue

system can be obtained by contacting Ideal Boilers.

All joints or connections in the ue system must be impervious

to condensate leakage. Low points in the ue system should be

drained using pipe of material resistant to condensate corrosion.

All drains in the ue should incorporate a water trap.

Care should also be taken in the selection of ue terminals as

these tend to accentuate the formation of a plume and could

freeze in cold weather conditions.

Care should be taken to ensure the specication of the chimney

is suitable for the application by reference to the manufacturers

literature.

NOTE:- Long Flues

It is recommended that a support bracket is tted at least every

1m of ue length and a bracket must be tted at every ue joint to

ensure ue seal and alignment of ue.

5

- Installation & Servicing

Loading...

Loading...