34

INITIAL LIGHTING

1. Check that the system has been lled and the boiler is

not air locked - air in the boiler could damage the heat

exchanger. For this reason if an automatic air vent has

been tted it must never be off.

2. Check that all the drain cocks are closed and any valves in

the ow and return are open.

3. Check that the GAS SERVICE COCKS ARE OPEN.

4. Check the indication on the pressure gauge. If the pressure

is less than 0.8 bar the installation should be lled up rst

(sealed system only).

5. Switch the electricity supply ON to all modules and check

that all the external controls are calling for heat. Check that

the boiler is in On Mode (see Frame 28).

6. The header pump switches on and the rst module fan

switches on. After 2 mins the rst module will ignite and

then the burner will modulate to satisfy the heat demand.

Additional modules will be switched on at regular intervals.

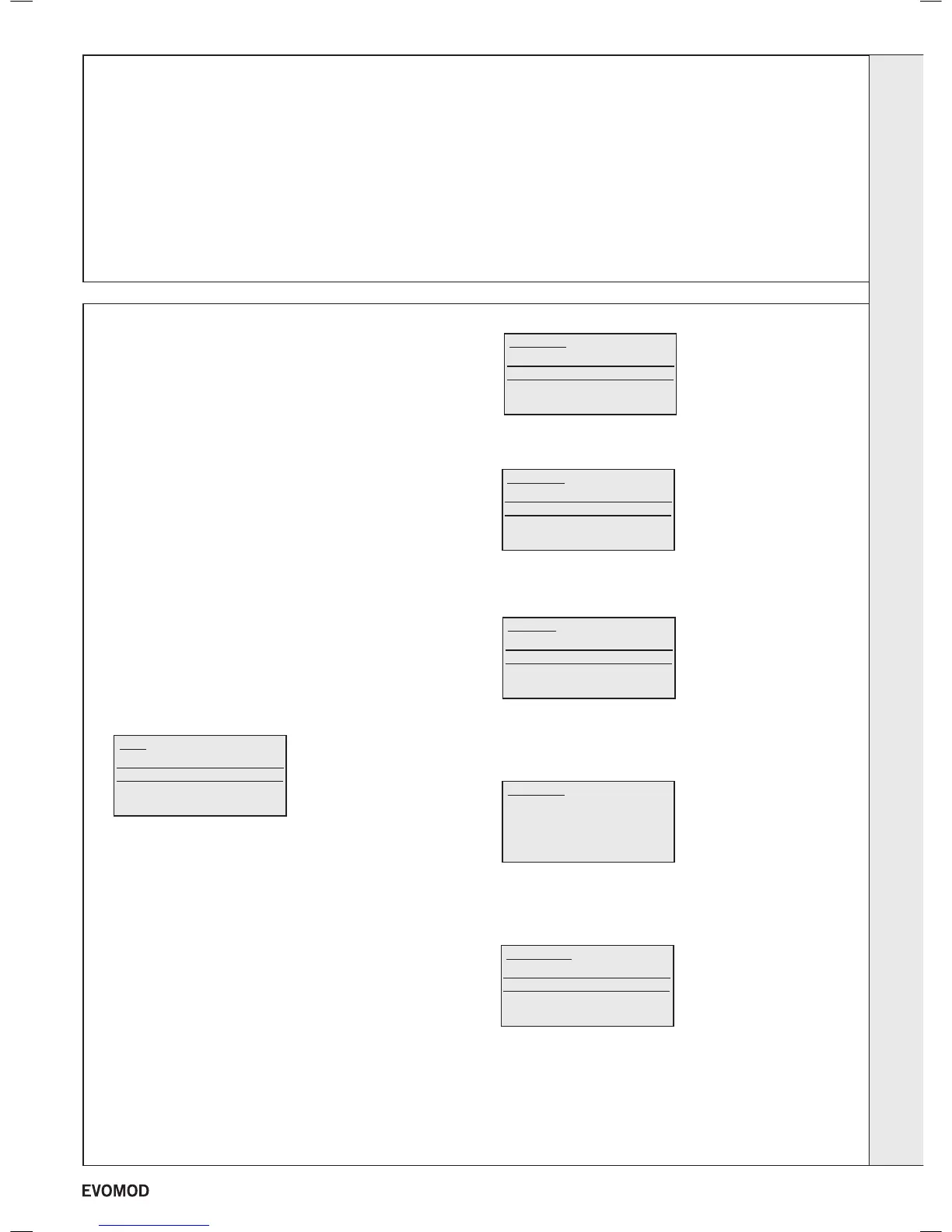

If after 5 attempts the module has failed to light then it

will lock out. To restart the Ignition sequence press the

reset button and a screen similar to the following will be

displayed.

Rotate the knob until the module you wish to reset is

highlighted and then press reset again.

7. The gas valves are preset at the factory to nominal values.

Dependant on site installation conditions (e.g. ue length)

the module performance can vary slightly. To check the

performance, measure the CO/CO

2

values at maximum and

minimum rates whilst adjusting the gas valves if necessary.

To set a module to run at either maximum or minimum rate

for 5 minutes press SELECT and the following screen will

appear.

Rotate the knob clockwise until a screen similar to the

following is displayed.

Press SELECT and a screen similar to the following will be

displayed.

Rotate the knob until Service is highlighted and press

ENTER and a screen similar to the following will be

displayed.

Rotate the knob until service for the appropriate module is

highlighted and press ENTER and a screen similar to the

following is displayed.

Rotate the knob until Minimum or Maximum is highlighted

as required and press ENTER.

8. Operate the boiler for 5 minutes and check the gas rate

(Table 1). You should obtain a value at least 90% of the

nominal.

9. Ret the module cover. See Frame 14.

33

COMMISSIONING AND TESTING

A. ELECTRICAL INSTALLATION

1. Checks to ensure electrical safety should be carried out

by a competent person.

2. ALWAYS carry out the preliminary electrical system

checks, i.e. earth continuity, polarity, resistance to earth

using a suitable meter.

WARNING. Whilst effecting the required gas soundness test and purging air from the gas

installation, open all windows and doors, extinguish naked lights and DO NOT SMOKE.

B. GAS INSTALLATION

1. The whole of the gas installation, including the meter,

should be inspected and tested for soundness and then

purged in accordance with the recommendations of the

relevant standards listed on page 4.

In IE refer to I.S.820:2000.

Reset

Normal Operation

Reset Module 1 01

Ideal 750kW

Normal Operation

Set Flow Temp

Set ON/OFF

Ideal 750kW

Set Flow Temp

Set Off/On

State of Inputs

State of outputs

Set Off/On

Off Mode

On Mode

Service

Service Mod 1

Off

Minimum

Maximum

Service Mod

Normal Operation

Service Mod 1

Service Mod 2

Service Mod 3

INSTALLATION

31

- Installation & Servicing

Loading...

Loading...