40

SERVICING SCHEDULE

To ensure the continued safe and efcient operation of the

appliance it is recommended that it is checked at regular

intervals and serviced as necessary. The frequency of

servicing will depend upon the installation condition and usage

but should be carried out at least annually.

Ideal Boilers does not accept any liability resulting from

the use of unauthorised parts or the repair and servicing of

appliances not carried out in accordance with the Company's

recommendations and specications.

Note.

Some build-up within the heat exchanger assembly is quite

usual with this type of condensing boiler. Though removal

and cleaning is recommended annually, the heat exchanger

and condensate trap must be inspected and cleaned after a

maximum of 2 years operation.

1. Light the boiler and carry out function checks, noting any

operational faults.

2. Run the boiler for 5 minutes and then check the gas

consumption rate. Refer to Frame 34 for reference on how

to force the burner to maximum and minimum rates.

3. For correct boiler operation the CO/CO

2

ratio of the ue gas

on each module should not be greater than 0.004 ratio and

the CO

2

values should be correct to the gures in Table 1

on Page 2.

4. If the combustion reading is greater than the acceptable

value AND the integrity of the combustion circuit seals and

ue system have been veried, and the gas inlet pressure

has been checked.

5. Remove and inspect the fan/venturi assembly. Refer to

Frame 45.

6. Remove the burner assembly and inspect the electrodes

and sightglass. Refer to Frame 46.

7. Remove and clean the burner. Refer to Frame 46.

8. Inspect the heat exchanger through the burner opening.

If there are signs of oxide build up, clean the exposed heat

exchanger surface with a suitable brush. Refer to Frame

47.

9. Clean the condensate traps. Refer to Frame 48 & 49.

10. Check that the ue terminal and air inlet are unobstructed

and that the uing and ducting are correctly sealed.

REPEAT PROCEDURE FOR BOTH SLAVE AND MASTER

MODULES.

11. After servicing refer to Frame 39 for nal safety checks.

41

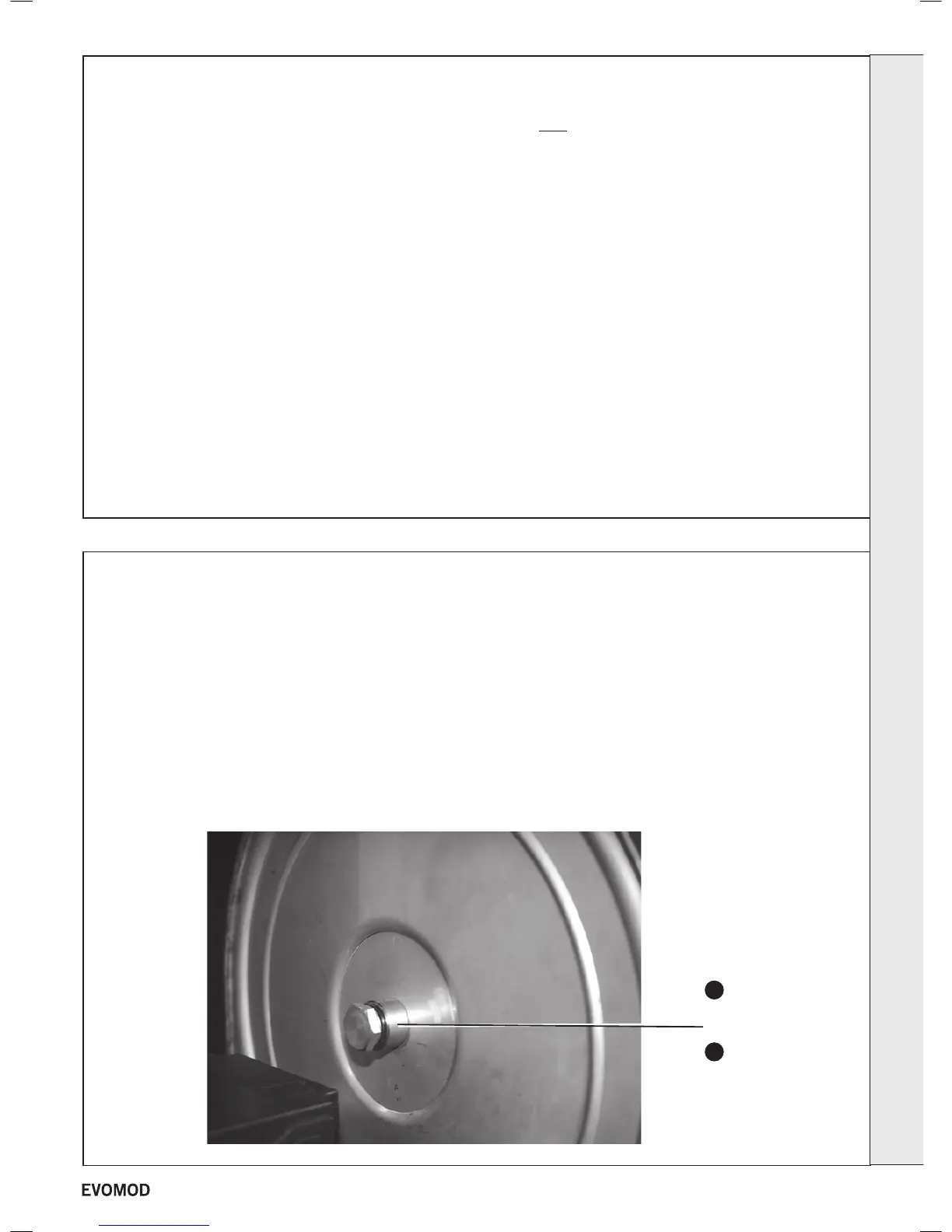

GAS VALVE ADJUSTMENT

Maximum rate adjustment

1. Switch the boiler on and operate for 5 minutes.

2. See Table 1, Page 2 for minimum and maximum gas rate

setting.

3. Set the module to maximum output (see Frame 34).

4. Connect a suitable ue analyser to the ue sampling point of

the Master Module.

5. Using the maximum rate adjustment screw, adjust the

master module gas valve, if necessary, until the CO

2

measures 9.1% ± 0.2 (nb. clockwise reduces CO

2

).

6. Connect a suitable ue analyser to the ue sampling point of

the Slave Module.

7. Using the maximum rate adjustment screw, adjust the

Slave Module gas valve until the CO

2

measures 9.1% ± 0.2

(nb. clockwise reduces CO

2

).

8. Repeat until all modules are set at max.

Flue sampling

point

4

11

If the boiler contains more than 1 Module tted with individual gas valves. All gas valves must be adjusted independently.

continued ..........

SERVICING

35

- Installation & Servicing

Loading...

Loading...