To start up the boiler, proceed as follows:

ensure that the declaration of conformity of in stal la tion is

supplied with the appliance;

ensure sealing e ciency of the gas intake circuit with the

shuto valves closed and then with the valves open and

the gas valve deactivated (closed); the meter must not

indicate gas transfer for at least ten minutes;

ensure that the gas used corresponds to spec i ca tions for

ensure connection to a 230V-50Hz power mains, correct

L-N polarity and the earthing connection;

switch on the boiler and ensure correct ignition;

ensure that the maximum, intermediate and min i mum gas

ow rate and relative pressure val ues conform to speci ca-

tions in the booklet on page 122;

ensure activation of the safety device in the event of gas

supply failure, as well as the relative ac ti va tion time;

ensure activation of the main switch downstream of the

boiler and inside the boiler;

check that the intake and/or exhaust terminals are not

ensure activation of the safety pressure switch in the event

ensure activation of all regulation devices;

seal the gas ow rate regulation devices (if set tings are

ensure production of hot domestic water;

ensure sealing e ciency of water circuits;

ensure adequate ventilation and/or aeration of the boiler

If any checks/inspection give negative results, do not start

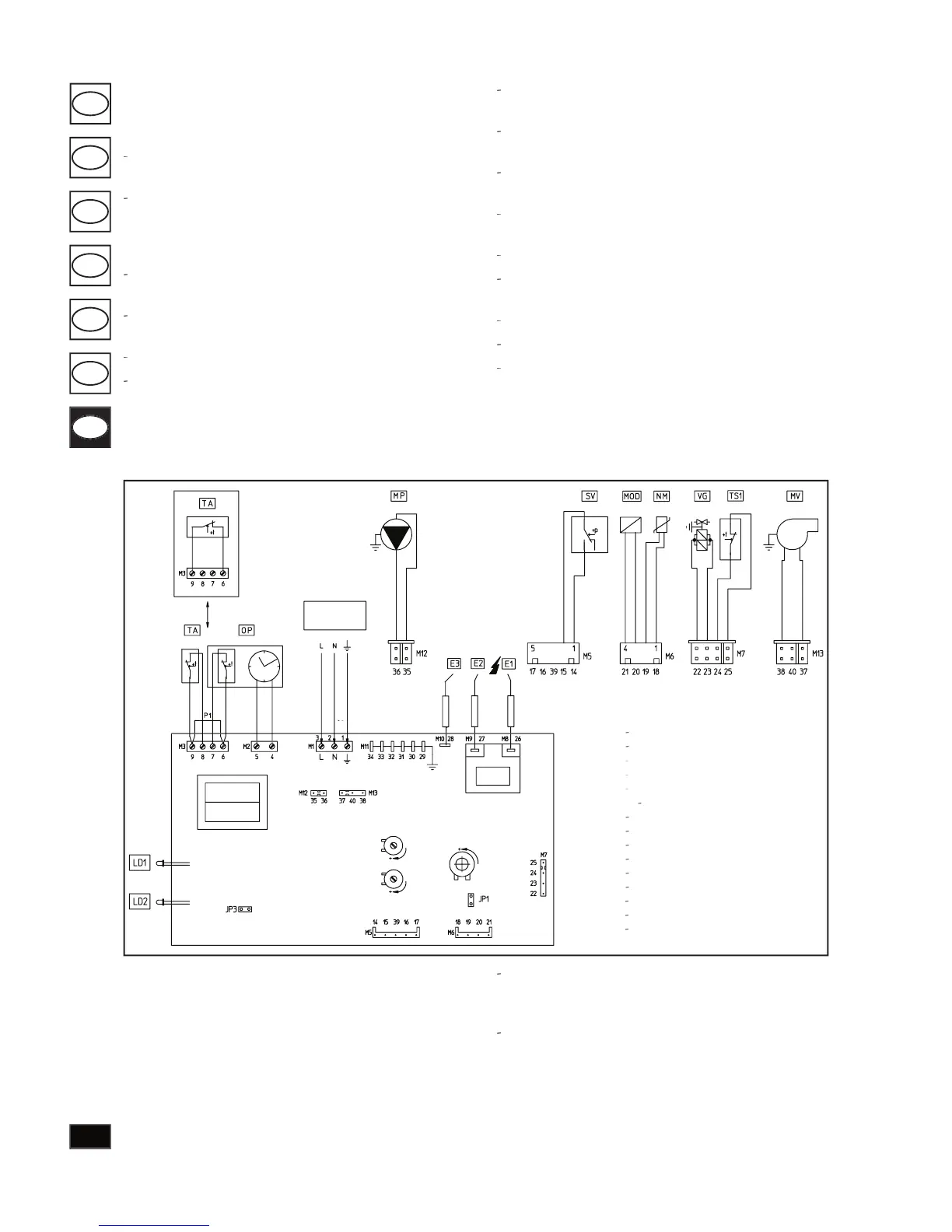

Room thermostat and clock programmer: the boiler is

designed for ap pli ca tion of an room thermostat (TA) and

of a clock programmer (CP). If you have only one of these

devices, connect to ter mi nals 6 and 9 and remove jumper P1.

Whereas if you have both, connect (TA) on terminals 8 and

9, and (CP) on terminals 6 and 7, after removing P1.

Electronic card function options.

e electronic card is equipped with jumpers de signed to

regulate boiler operation according to spe ci c in stal la tion

Eolo Mini S electrical circuit diagram.

Jumper JP1: when inserted the appliance op er ates with

LPG; when removed the appliance operates with natural

JP3 jumper; when inserted, after the heating tem per a ture

is reached the boiler only re-starts after 3 minutes; when

removed, the interval before re-start changes to 30 seconds,

useful for convection fan systems.

Room thermostat On/O (optional)

Temp. overload safety thermostat

Loading...

Loading...