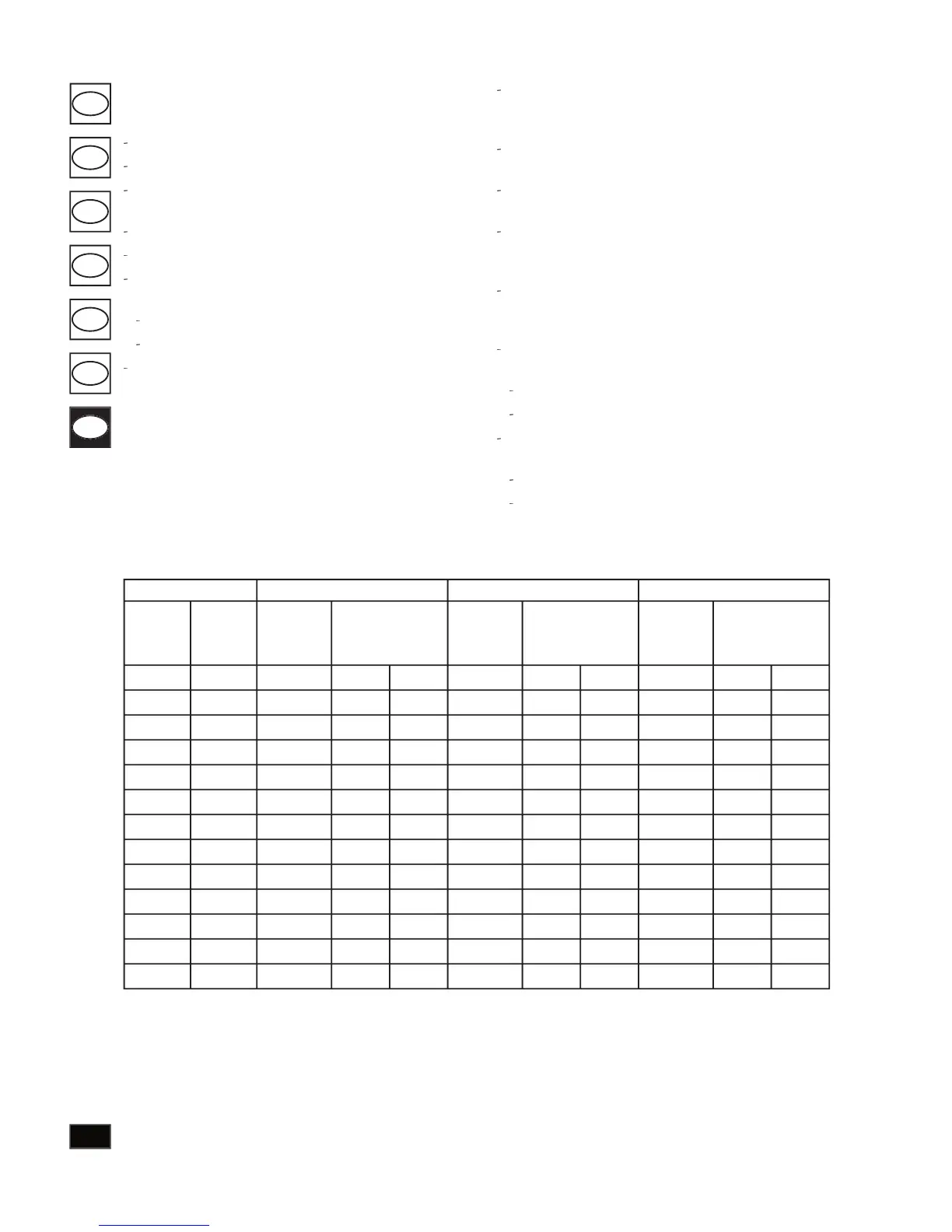

Pressure values speci ed in the table indicate the dif-

ference of pressure values between the gas valve outlet and

the combustion chamber. Ad just ments are therefore carried

out with the di erential pressure gauge ( “U” or digital type)

with the sensors inserted in the test pressure outlet of the

modulating adjustable gas valve and on the sealed chamber

pos i tive pressure test outlet . Power data speci ed in the

table refer to a 0,5 metre intake/exhaust pipe. Gas ow rates

refer to heat power below temperature of 15°C and at a

pres sure of 1013 mbar. Burner pres sure values refer to use

Annual appliance maintenance.

e following checks and maintenance should be per formed

Clean the ue side of the heat exchanger.

Make a visual inspection of the ue extraction hood for

Ensure correct ignition and operation.

Ensure correct settings of the burner.

Verify correct operation and adjustments of the ap pli ance,

activation of the electrical main switch on the boil er;

activation of the system control thermostat.

Ensure sealing e ciency of the gas intake circuit; insert a

“U” or digital type pressure gauge in the pressure socket

upstream of the gas valve and sub se quent ly closing the

boiler shuto valve (cock) and closing the gas valve, no

pressure variation must occur in the next ve minutes on

Ensure activation of the device for protection against the

ionisation ame control gas; ac ti va tion time must be less

Visually inspect to check for leakage of water or oxidation

Check visually that the water safety drain valve is not

Check that the charge of the expansion vessel af ter dischar-

ging system pressure to the zero set ting (check via boiler

pressure gauge), is at 1 bar.

Check that the system static pressure (in cold con di tions

and after system recharging via the lling valve ) is between

Check visually that the safety and control devices have not

been tampered with and/or shorted, in par tic u lar:

temperature safety thermostat;

Ensure correct maintenance and condition of the electrical

installation with particular reference to:

electrical cables must be inside the channels;

no traces of black marking or burns.

Eolo Mini S variable heating power.

Loading...

Loading...