IMO GmbH Gässlesweg 6 D-75334 Straubenhardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

26

GmbH

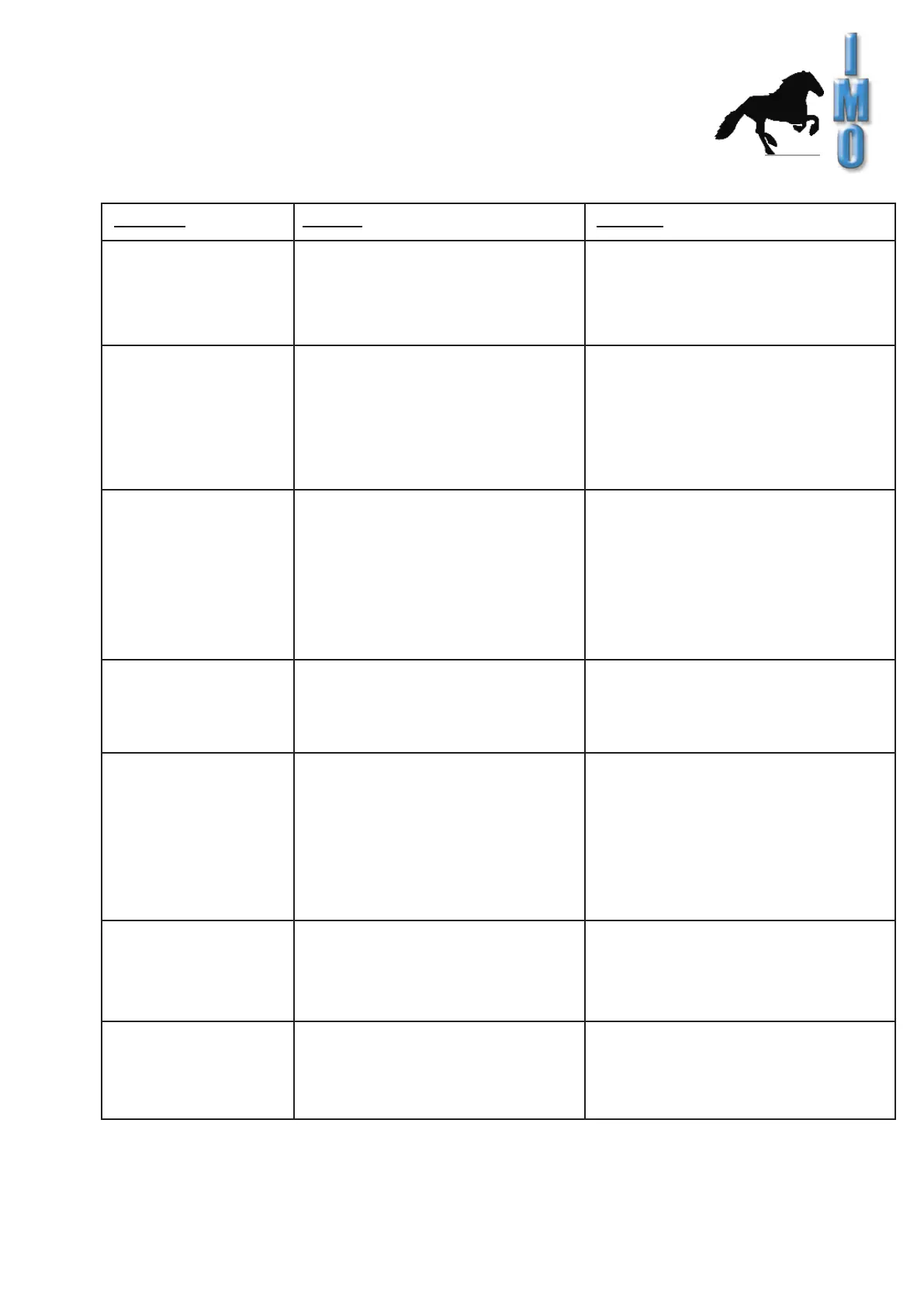

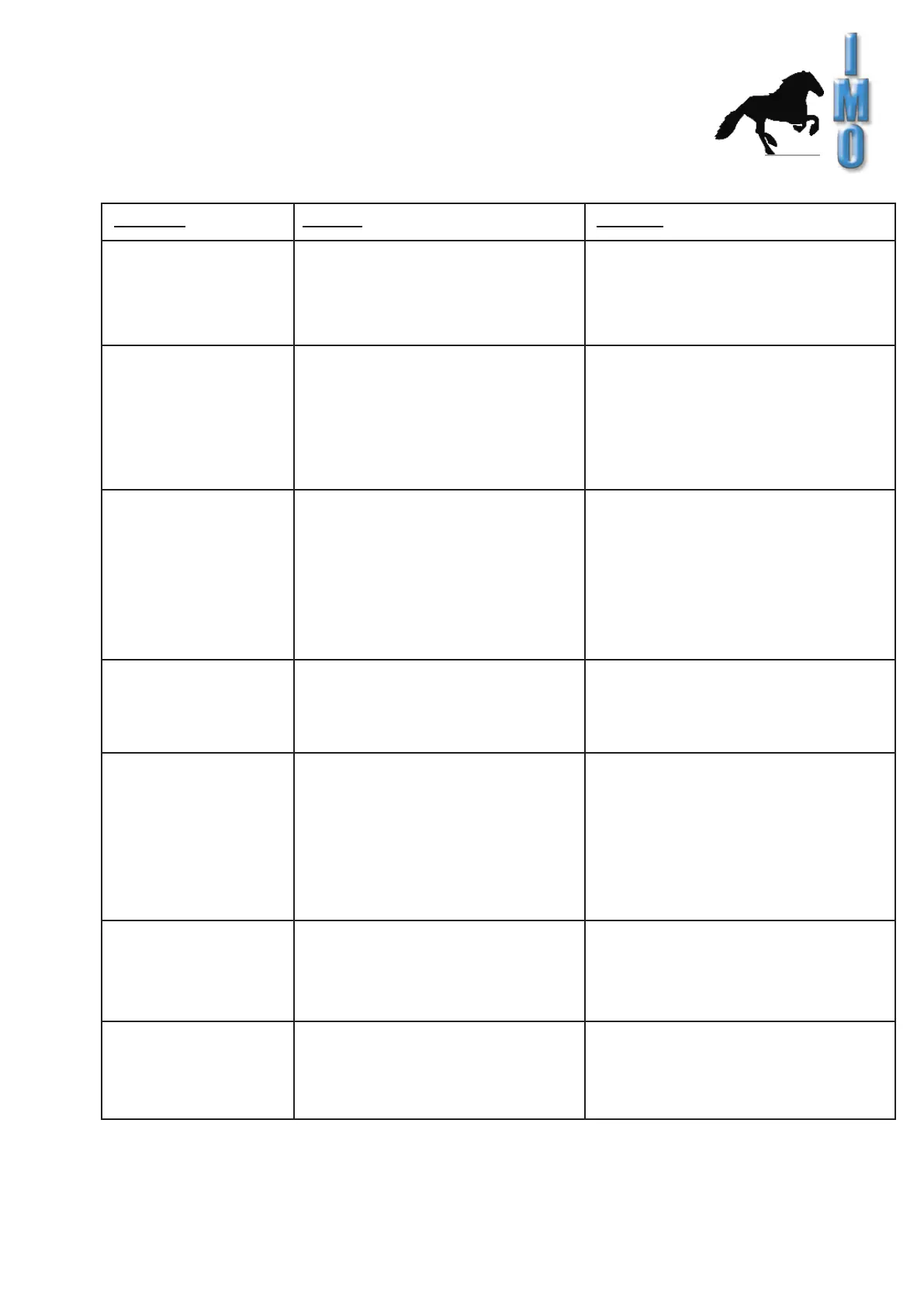

7. Error messages

Message

Causes Solution

A1

Defect of internal

lead valve

- Machine-lateral inlet valve is leaky

- Inlet hose was extended

- Valve has to be replaced

- Use inlet hose in original lenght

A2

Defect of external

lead valve

- External inlet valve is leaky

- Inlet hose was extended

- air inside of the NE-deionizer-unit

- Valve has to be replaced

- Use inlet hose in original lenght

- Remove NE-deionizer-cartridge

(page 6)

A3

Defect of inlet valve or

inlet blocked

- Defect of machine-lateral or inlet-lateral

inlet valve

- Inlet valve isn’t connected

- Water-inlet locked

- Inlet hose buckled

- Valve has to be replaced

- Connect electric cable for inlet-lateral valve

- Open water tap

- Control inlet hose and eliminate the buckle

A4

Defect of dosing

- Defect of control dosing pump

- Dosing opening is plugged

- Contact customer service

- Unscrew dosing cap and clean under

flowing water

S1

Short circuit of

NTC water

- Water below the machine

- NTC defect

- Defect of mainboard

- Look for cause for humidity and

eliminate; let machine dry

- Contact customer service

- Contact customer service

- If the error repeats, please contact us

S2

Interruption of

NTC water

- NTC defect

- Defect of inlet to NTC

- Defect of mainboard

- If the error repeats, please contact us

S3/S5

Short circuit

of NTC air

- Defect of NTC on the blowing out side/

sucking in side of drying unit

- Defect of dryness mainboard

- If the error repeats, please contact us

Loading...

Loading...