IMO GmbH Gässlesweg 6 D-75334 Straubenhard t Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

27

GmbH

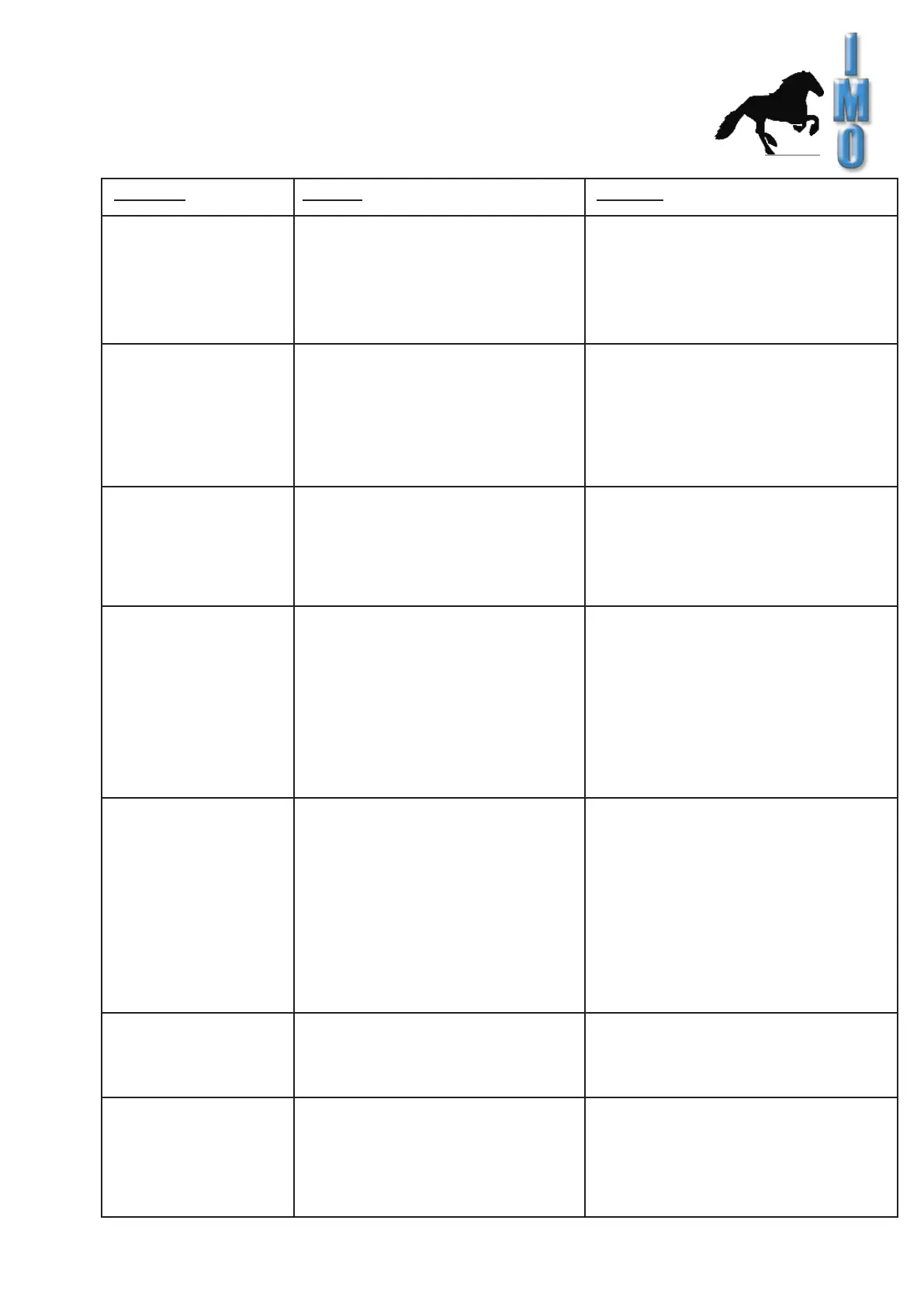

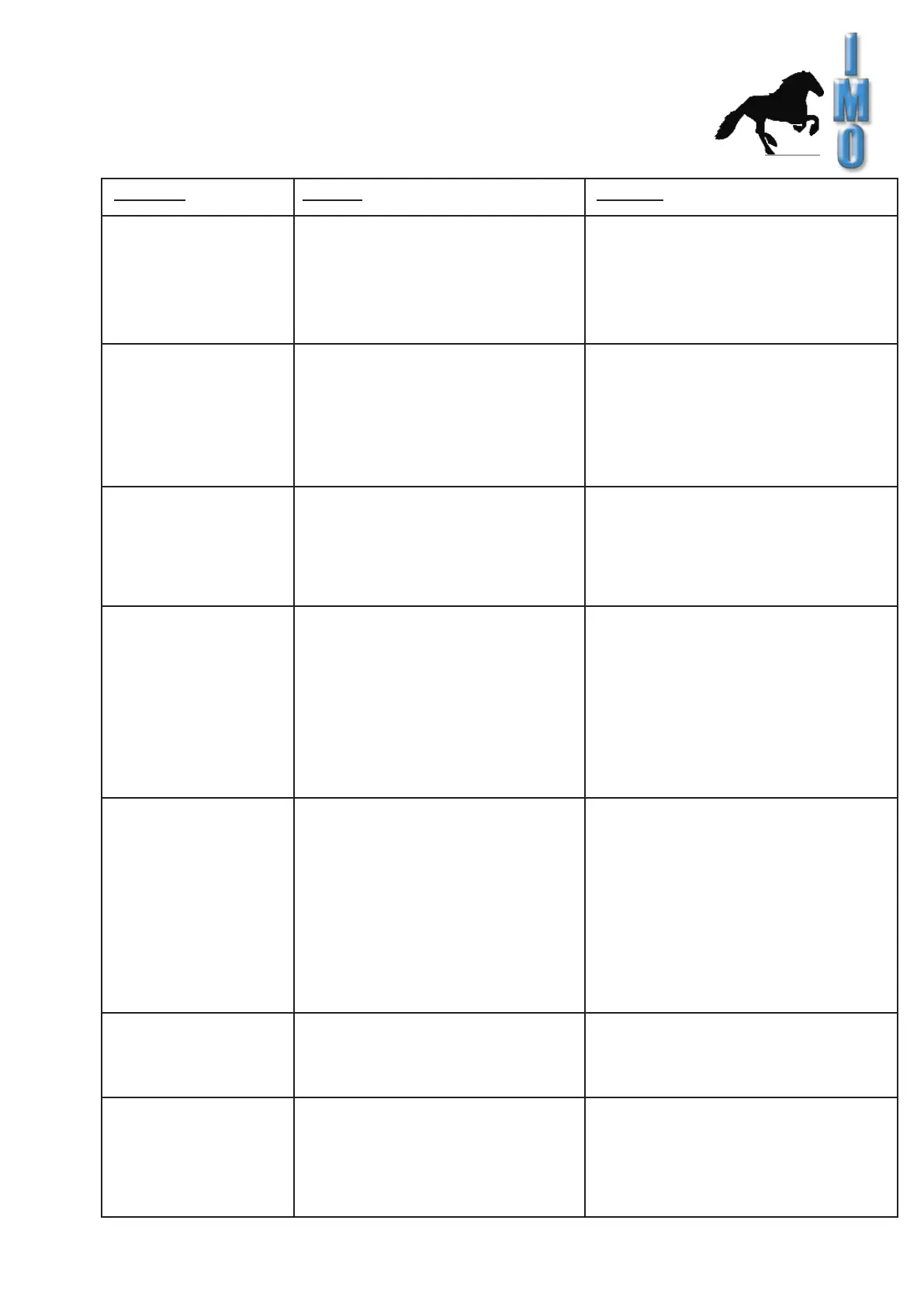

Message Causes Solution

S4/S6

NTC air break

- Defect of NTC at blowing out/sucking

in side of drying machine

- Defect of plug or rather feed cable to

one of the NTCs

- Defect of mainboard drying

- If the error repeats, please contact us

S7

Defect of water indicator

- Level sensor still switches before

water indicator

- Defect of level sensor

- Defect of water indicator

- Defect of mainboard

- Check feed cable of water indicator

and level sensor

- If the error repeats, please contact us

S9

Maximum temperature

of water exceeded

- Defect of control for heating water

- Defect of NTC water

- Defect of mainboard

- If the error repeats, please contact us

S10

Maximum temperature

of air exceeded

- Defect of control for heating air

- Defect of NTC at blowing out side of

drying machine

- Defect of plug or rather feed cable to

one of the NTCs

- Defect of mainboard drying

- If the error repeats, please contact us

S12

Sprayarm blocked

S13 - Dosaged too strongly foaming cleaner

- See also errors S12

- Use Activator

- See also errors S12

S14

Cleaner DOSx is empty

- Detergent can is empty

- Dosing hose is buckled

- Dosing hose is plugged

- Connect new detergent can

-Water circulation is obstructed

-Magnet on lower spray arm

defective (rusted / fallen off)

-Spray arm worn out;

Particles in spray arm hub

-spray arm has become caught in

cables or similar

-water loss due to waste water

hose ending to low

(see also Troubleshooting S15)

-Check if the spray arms can be turned

rotate easily

-Check the sieves for contamination

and clean if necessary

-Correct detergent dosage

ensure

-Do not stack wash ware too tightly

-Use a different flux

Too much foam in

machine

- Air bubbles in the dosing hose

- Eliminate buckle

- Eliminate blockage or replace hose

- Deaerate the dosing hose by sucking in

sufficient much cleaner to do this

(Main menu -> Setup -> Detergent

-> Suck in cleaner)

Loading...

Loading...