IMO GmbH Gässlesweg 6 D-75334 Straubenhardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

28

GmbH

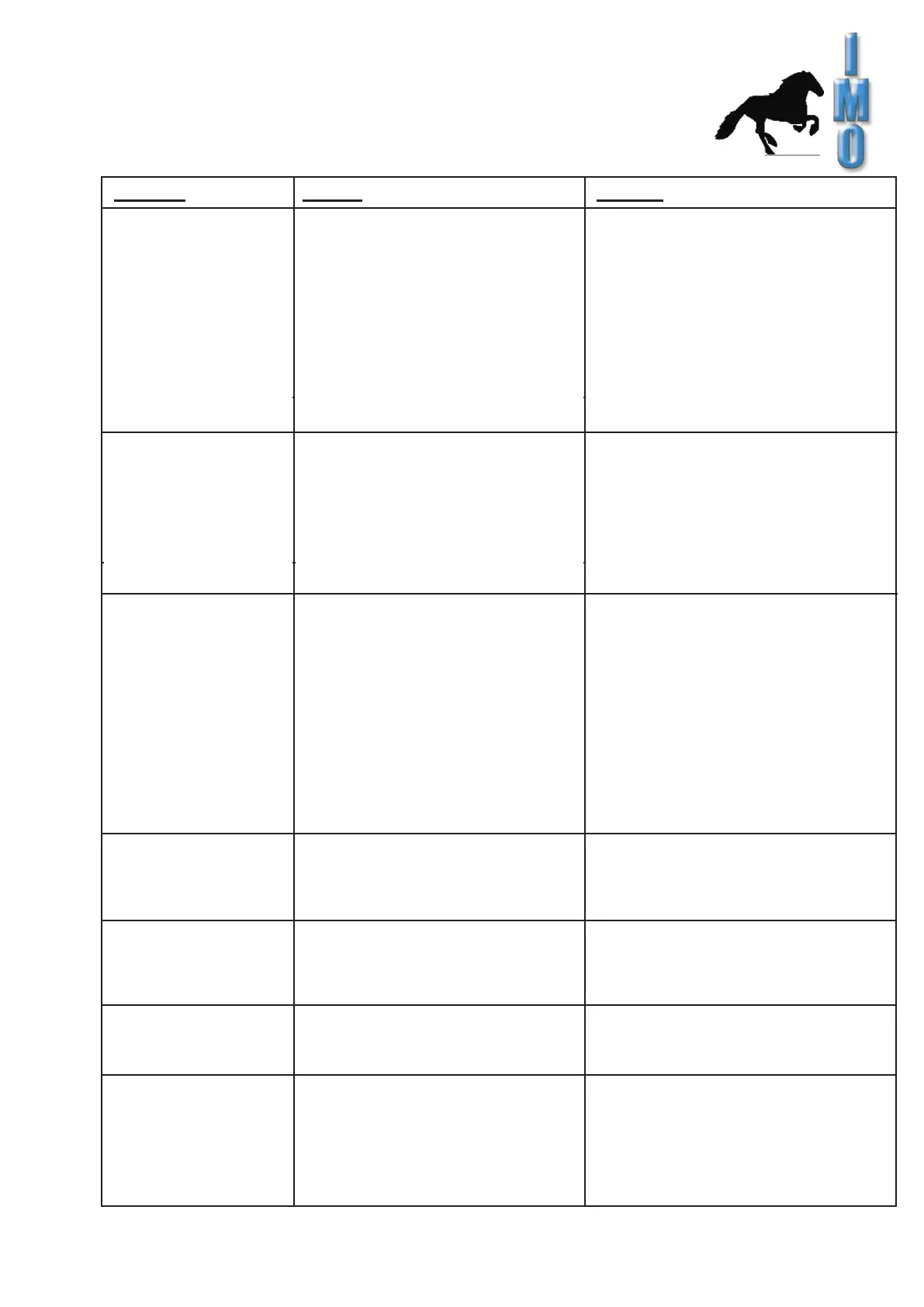

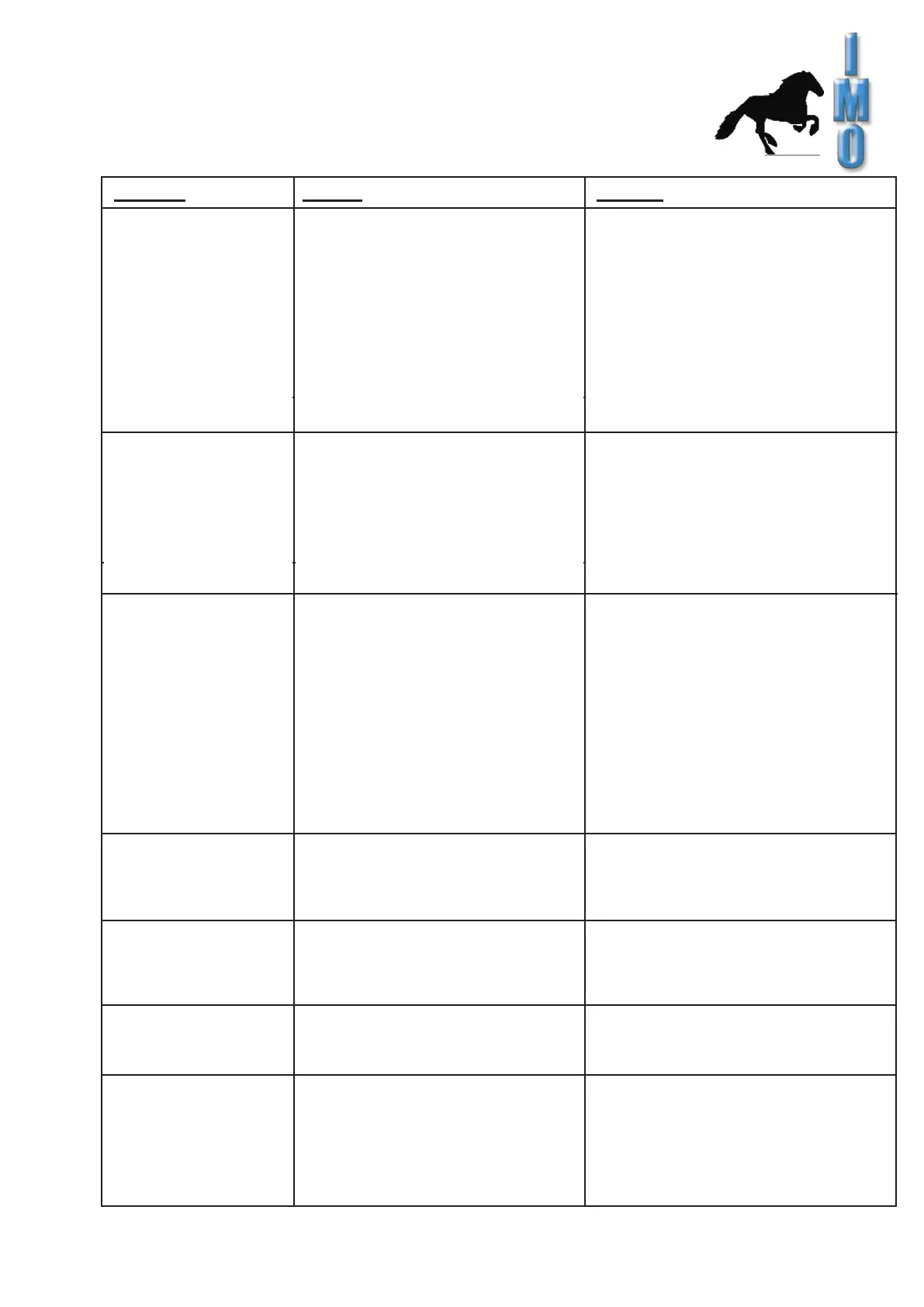

Message Causes Solution

S15

Loose of water

S17

Released safty of

heating for air

- The temperature rise safty device

responded

- Defect of turbine

- Air filter messy

- Pull power plug! Remove rear sewer

cover and switch on the temperature safe

above at the heater housing

- Check, wether turbine starts

- Check air filter and possible replace

- The air openings and air blow-out ports in

machine interior may not be covered by

cleaning goods

- If error repeats, please contact us

S18

Wrong cleaner:

doesn’t foam

- Even after longer dosing no foaming

can be recognized

- Check if correct detergent is attached

according to detergent definiton or dosing

pump-allocation

S19

Wrong cleaner:

doesn’t defoam

- Even after longer dosing foaming

doesn’t decrease

- Check if correct detergent is attached

according to detergent definition or dosing

pump-allocation

S20

Ion exchanger is

exhausted

- Ion exchanger used up - Attache new or regenerized ion

exchanger patrone

T1

Fill time is overshot

- Water pressure is to less

- Water inlet hose is defect

- Possibily existing water shunt-off valve

is not completely open

- Check water inlet and water pressure

- Start program again

S16

Discharge of water

- Water circulation leaky

- Discharge of water at bottom of

machine

- Too strong foaming powe

- Switch off the machine, tear net apart

and tip it back easy, so that discharged

water can run off.

-Check machine for discharged water,

eliminate leackages, or evite

foaming power

- Arrange reset, start program new

- Waste water hose on machine side

and hose end after the

waste water filter system is mounted

too low or not ventilated

- Scooping parts in the wash ware

- Dirt trap and/or strainer insert

dirty

- Water indicator defective

- Too much foam during filling

- Hose end must end above the

above the machine installation surface

in order to avoid a suction effect.

Ventilate the waste water system to

to prevent negative pressure.

- Place the items to be washed in such a

way that the water can drain off well from

the parts

- Clean dirt trap and strainer insert

- If the error occurs repeatedly, contact

contact us

- Dose less cleaner or use activator AT

Loading...

Loading...