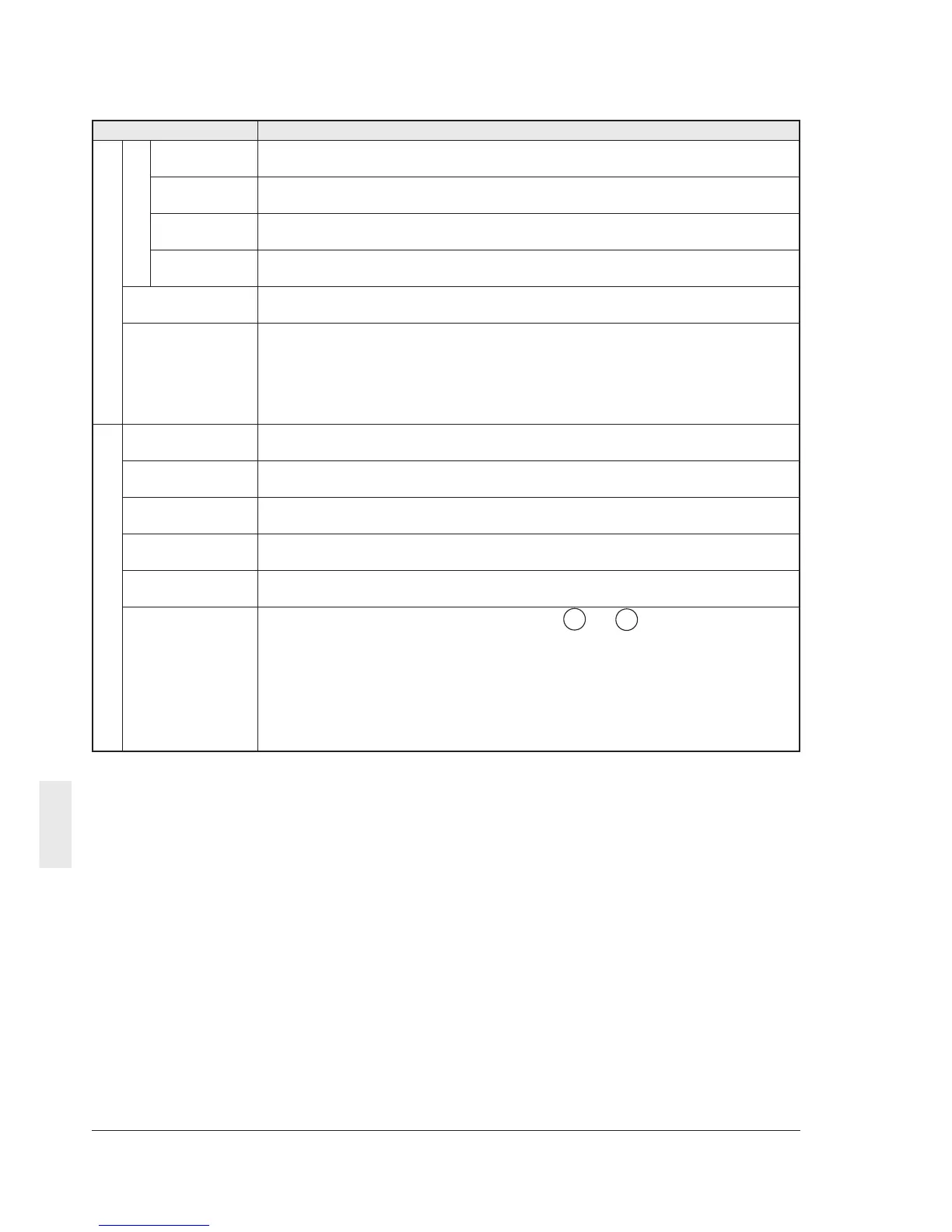

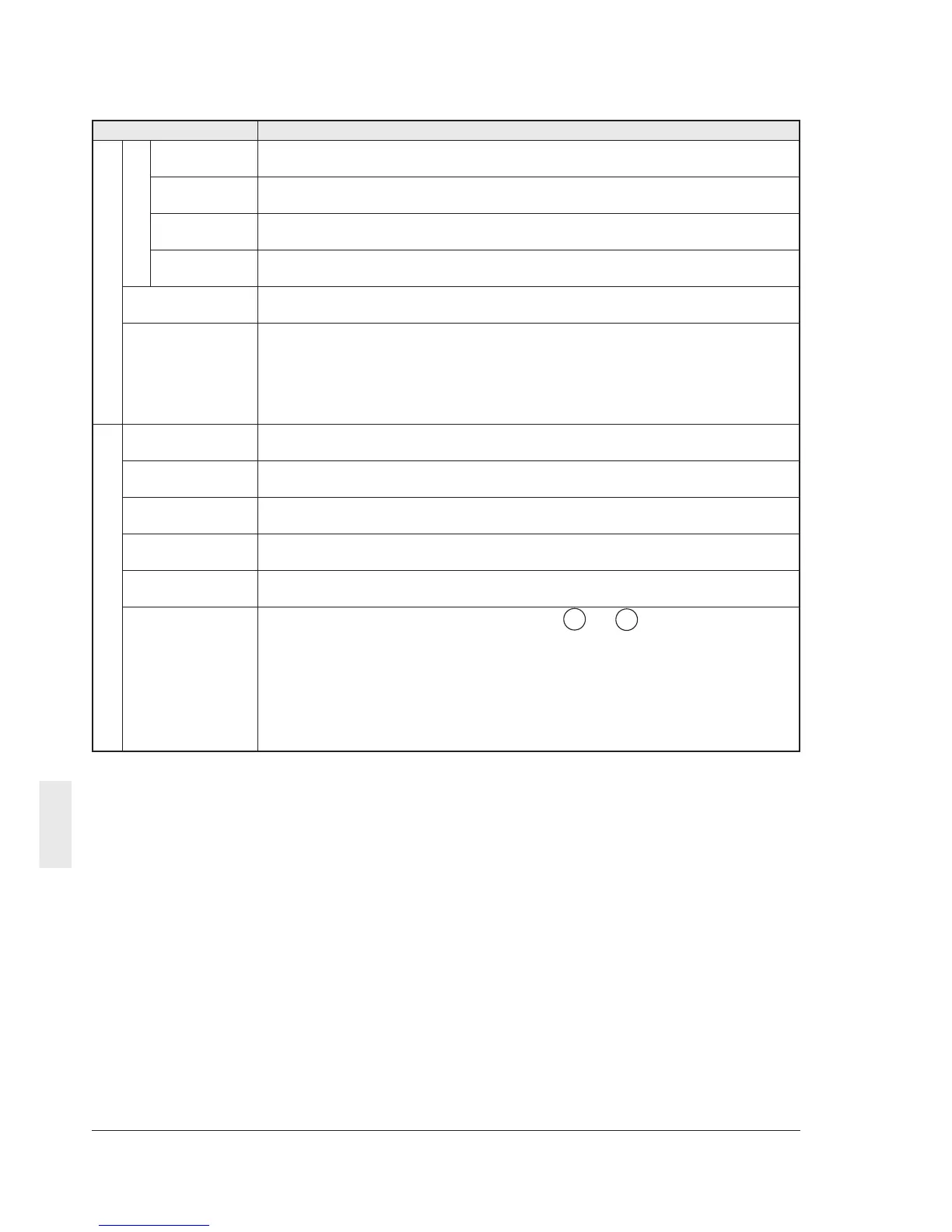

9-3 Specifications

9

Item Detail specifications

Maximum 50 to 400 Hz variable

frequency

Base 25 to 400 Hz variable

frequency

Starting

frequency 0.1 to 60.0 Hz variable, Holding time : 0.0 to 10.0s.

Carrier 0.75 to 15 kHz (The carrier frequency may automatically drop to 0.75 kHz to

frequency protect the inverter. )

Accuracy Analog setting: Within ± 0.2 % (25 ± 10 °C)

Digital setting: Within 0.01% (-10 to +50 °C)

Setting

resolution Analog setting: 1/3000 of maximum output frequency

Keypad panel setting: 0.01 Hz (99.99 Hz or lower), 0.1 Hz (100.0 to 400.0 Hz)

Link setting : «1/20000 of Maximum frequency

(0.003Hz at 60Hz,0.006Hz at 120Hz,0.02Hz at 400Hz)

or 0.01Hz (Fixed)

Voltage/freq. Adjustable at base and maximum frequency,

Characteristics with AVR control : 80 to 240 V(200V class),160 to 480V(400V class)

Torque boost Automatic:Automatic torque boost can be selected with code setting.

Manual: Setting by codes 1 to 31 (Boost for Variable torque available)

Starting torque Starting torque 200% or above

(with dynamic torque vector turned on, during 0.5 Hz operation)

DC braking Braking time (0.0 to 30.0 s), braking current (0 to 100%), braking starting

frequency (0.0 to 60.0 Hz) variable

Control method Sinusoidal PWM (Dynamic torque vector control) with "current vibration

suppression function" and "dead time compensation function"

Operation method Keypad operation: starting and stopping with and keys.

(Keypad panel)

Digital input signal: forward (reverse) operation, stop command (3-wire operation

possible), coast-to-stop command, external alarm, error

reset, etc.

Link operation: RS485 (Standard)

Profibus-DP,Interbus-S,DeviceNet,Modbus Plus,

CAN open (Option)

9-2 Common Specifications

Output frequency

Adjustment

Control

RUN

STOP

Loading...

Loading...