Chapter 5 General Reference 111

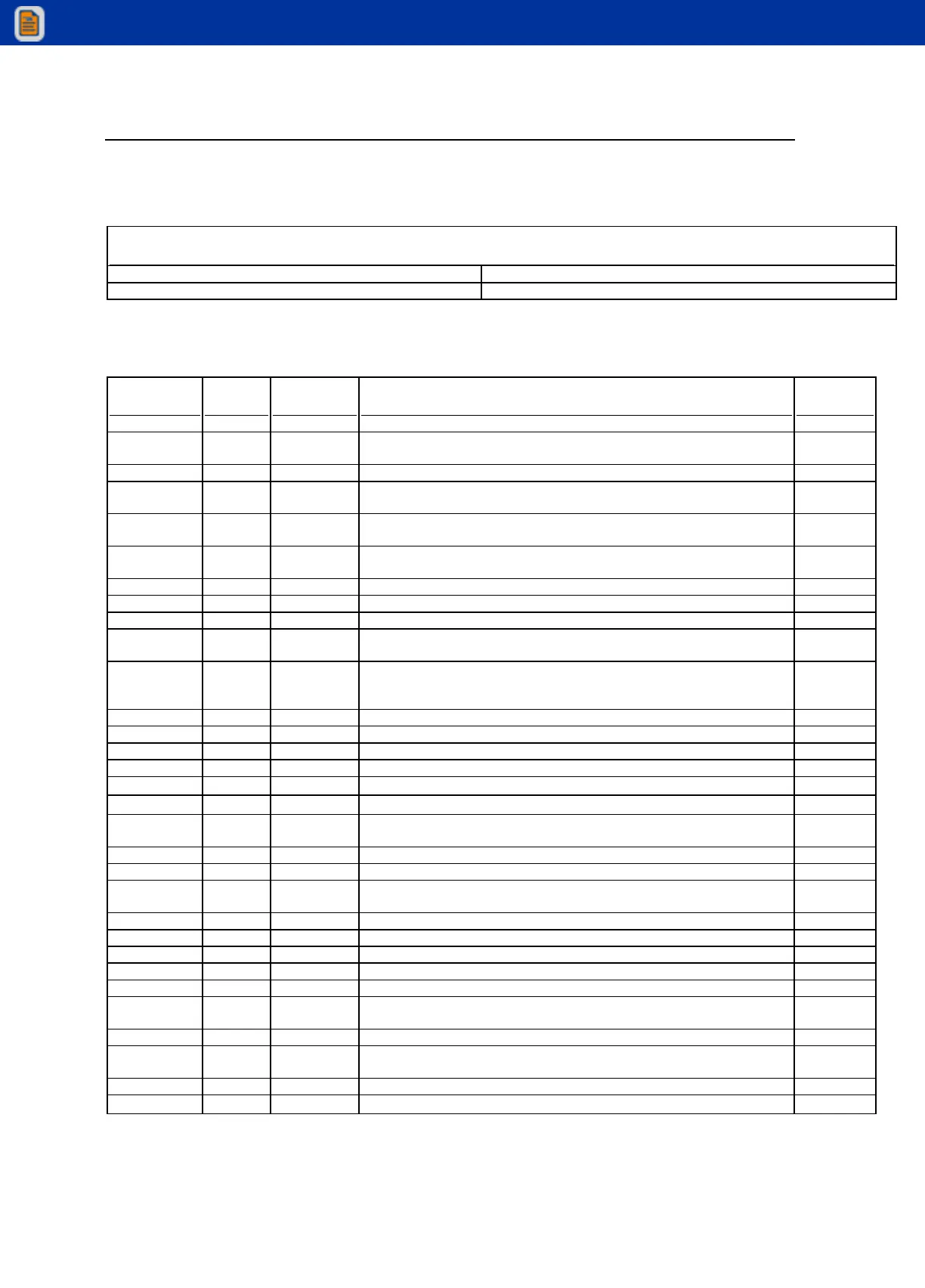

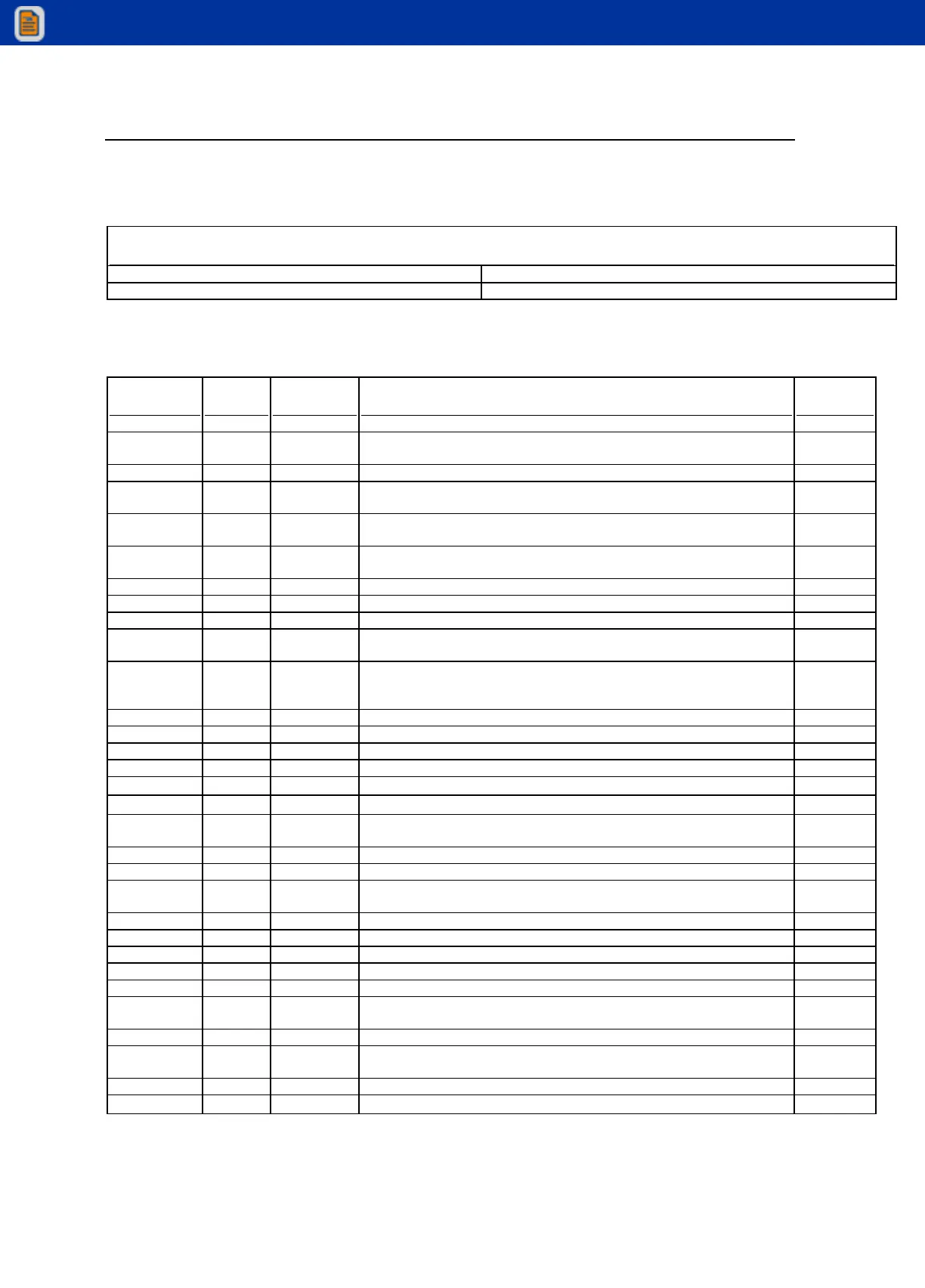

INSPECTION CHECKLIST STATUS KEY:

S = Satisfactory R = Recommendation (should be considered for corrective action)

X = Deficient (must be corrected prior to operation) NA = Not Applicable

FREQUENCY ITEM KEY INSPECTION DESCRIPTION STATUS

(S,R,X,NA)

D 1 Labels All load charts, safety & warning labels, and control labels are present

and legible.

D 2 Crane Check all safety devices for proper operation.

D 3 Controls Control mechanisms for proper operation of all functions, leaks and

cracks.

D 4 Station Control and operator's station for dirt, contamination by lubricants, and

foreign material.

D 5 Hydraulic

System

Hydraulic system (hoses, tubes, fittings) for leakage and proper oil

level.

D 6 Hook Presence and proper operation of hook safety latches.

D 7 Rope Proper reeving of wire rope on sheaves and winch drum.

D 8 Pins Proper engagement of all connecting pins and pin retaining devices.

D 9 General Overall observation of crane for damaged or missing parts, cracked

welds, and presence of safety covers.

D 10 Operation During operation, observe crane for abnormal performance, unusual

wear (loose pins, wire rope damage, etc.). If observed, discontinue

use and determine cause and severity of hazard.

D 11 Remote Ctrl Operate remote control devices to check for proper operation.

D 12 Electrical Operate all lights, alarms, etc. to check for proper operation.

D 13 Anti 2-Block Operate anti 2-block device to check for proper operation.

D 14 Other (Per customer requirements)

D 15 Other (Per customer requirements)

M 16 Daily All daily inspection items.

M 17 Cylinders Visual inspection of cylinders for leakage at rod, fittings, and welds.

Damage to rod and case.

M 18 Valves Holding valves for proper operation.

M 19 Valves Control valves for leaks at fittings and between stations.

M 20 Valves Control valve linkages for wear, smoothness of operation, and

tightness of fasteners.

M 21 General Bent, broken, or significantly rusted/corroded parts.

M 22 Electrical Electrical systems for presence of dirt, moisture, and frayed wires.

M 23 Structure All structural members for damage.

M 24 Welds All welds for breaks and cracks.

M 25 Pins All pins for proper installation and condition.

M 26 Hardware All bolts, fasteners and retaining rings for tightness, wear and

corrosion.

M 27 Wear Pads Presence of wear pads.

M 28 Pump &

Motor

Hydraulic pumps and motors for leakage at fittings, seals, and

between sections.

M 29 PTO Transmission/PTO for leakage, abnormal vibration, and noise.

M 30 Hyd Fluid Quality of hydraulic fluid and presence of water.

Loading...

Loading...