Chapter 3 Crane Reference 27

Control Valve Troubleshooting Chart

Theory of Operation – The control valve for this crane family consists of an electro-hydraulic

proportional valve with integral bypass which feeds four series on/off solenoid valves. The

proportional valve controls function speed. The on/off solenoid valves control which functions are

operated and the direction of operation. The valve manifold also includes a relief valve to limit

system pressure, a winch brake vent solenoid to apply the brake of a planetary winch, and a

high speed lower solenoid valve for the lift circuit. The proportional valve and the on/off valves

incorporate manual overrides for troubleshooting and emergency operation. The swing valve

uses a counterbalance valve in each work port to block flow in neutral. The swing brake shuttle

valve is not used for this application.

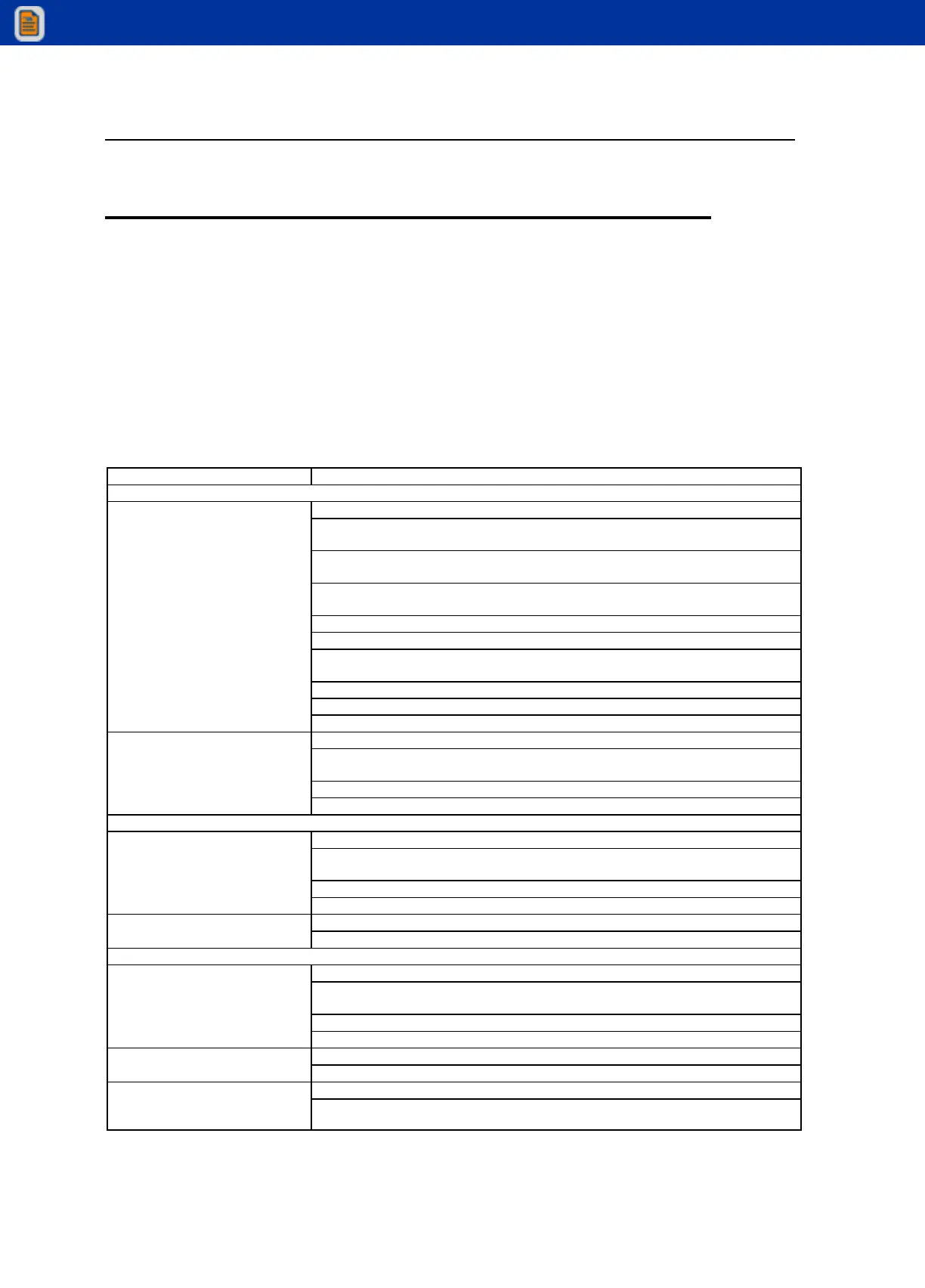

FUNCTION / ISSUE ACTION

WINCH

Check operating pressure at valve inlet, Port G.

1. Check and/or adjust main relief valve, Valve G. (Pressure setting - 3000 psi

-0/+100 psi)

2. Check and/or adjust outrigger relief valve, if unit is equipped with outriggers.

(Pressure setting - 3500 psi)

3. Engage proportional valve (Valve A) manual override while operating

function. If winch operates,

a. Verify power to Valve A.

b. Check Valve A for contamination.

4. Engage winch on/off control valve (Valve B) manual override while

operating function. If winch operates,

a. Verify power to Valve B.

b. Check Valve B for contamination.

Winch will not operate in either

direction.

5. Check winch counterbalance valve and PO check valve for contamination.

1. Check items 1 through 5 for "Winch will not operate in either direction."

2. Disconnect brake line and cap both ends to winch brake vent solenoid valve

(Valve F). If winch begins to lower:

a. Verify power to Valve F.

Winch will not lower.

b. Check Valve F for contamination.

EXTEND

1. Check items 1 through 3 in "Winch will not operate in either direction."

2. Engage extend on/off control valve (Valve C) manual override while

operating function. If extend operates:

a. Verify power to Valve C.

Extend cylinder will not extend.

b. Check Valve C for contamination.

1. Check items 1 and 2 for "Extend cylinder will not extend." Extend cylinder will not retract.

2. Check extend counterbalance valve for contamination.

LOWER

1. Check items 1 through 3 for "Winch will not operate in either direction."

2. Engage lower on/off control valve (Valve D) manual override operating

function. If lower operates:

a. Verify power to Valve D.

Lower cylinder will not extend.

b. Check Valve D for contamination.

1. Check items 1 and 2 for "Lift cylinder will not extend." Lower cylinder will not retract.

2. Check lower counterbalance valve for contamination.

1. Verify power to high speed lower valve (Valve H). Premature kick out of overload

system during rapid lowering of

a heavy load.

2. Check high speed lower valve for contamination.

Loading...

Loading...