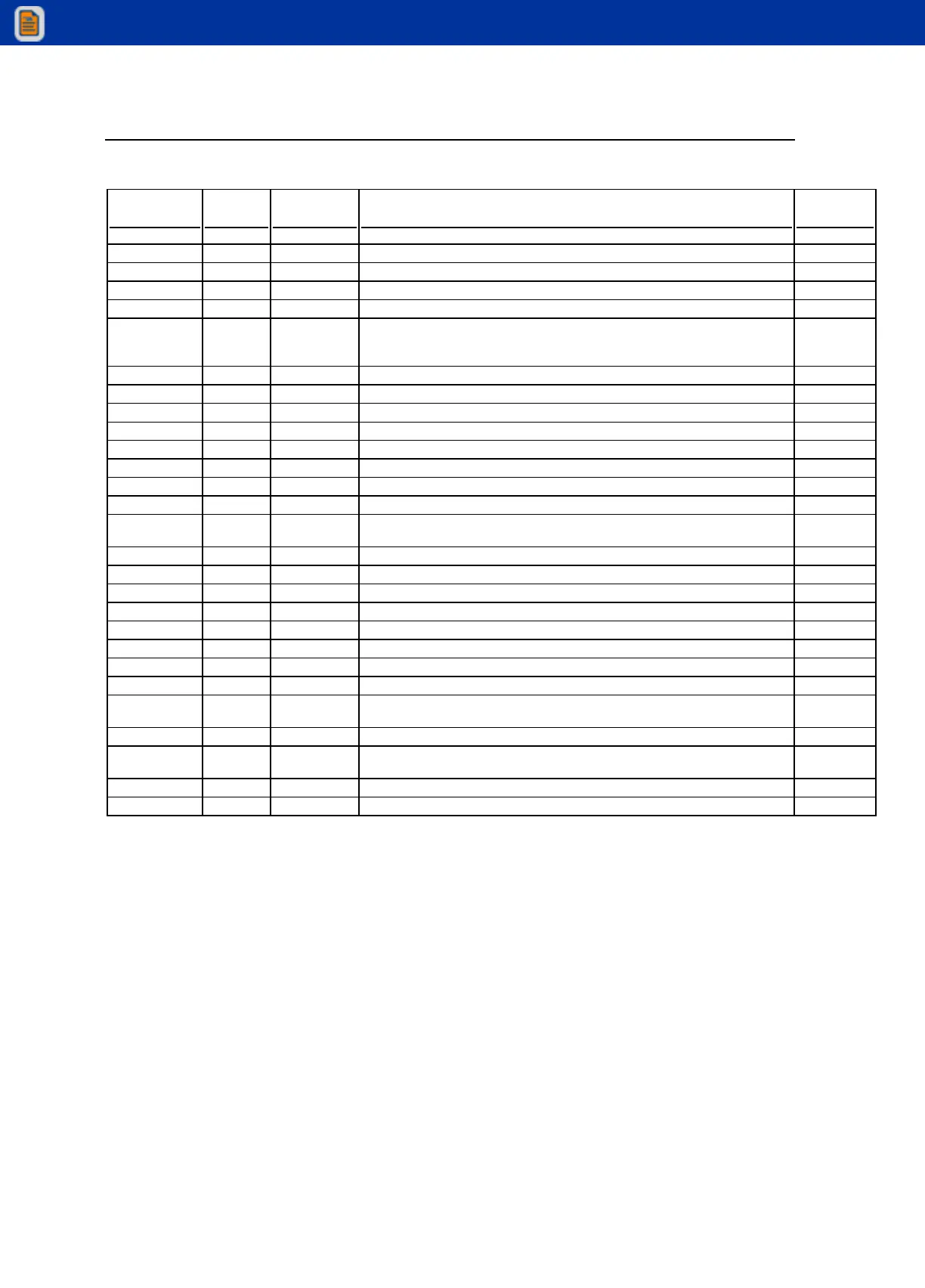

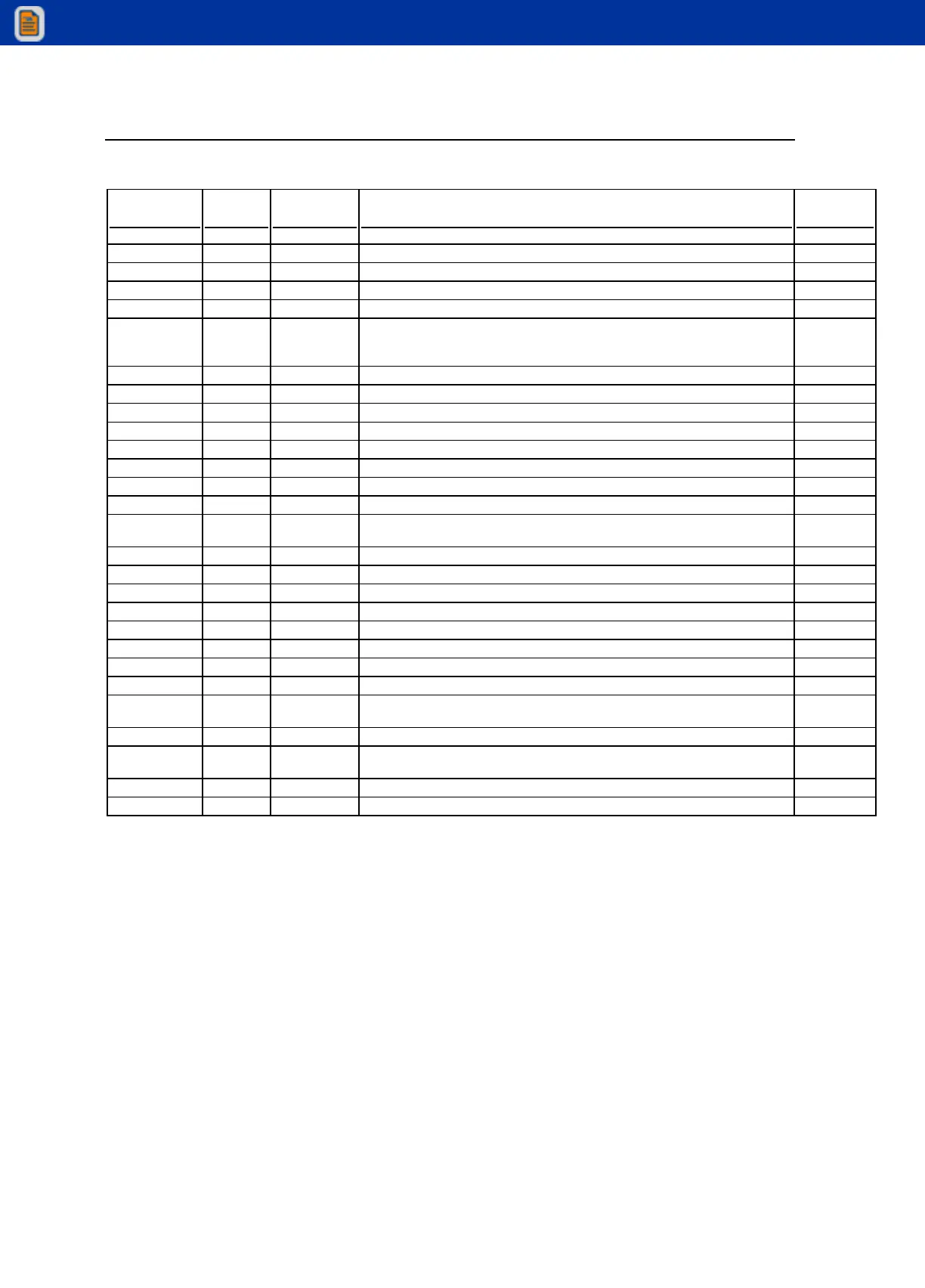

Chapter 5 General Reference 113

FREQUENCY

ITEM KEY INSPECTION DESCRIPTION STATUS

(S,R,X,NA)

76 • Load holding valve(s)

77 • Outrigger or auxiliary control valve(s)

78 • Other valves (per customer requirements)

79 • Other (per customer requirements)

Q 80 Cylinders Hydraulic cylinders for drifting, rod seal leakage and leakage at welds.

Rods for nicks, scores and dents. Case for damage. Case and rod

ends for damage and abnormal wear.

81 • Outrigger cylinder(s)

82 • Inner boom cylinder(s)

83 • Outer boom cylinder(s)

84 • Extension cylinder(s)

85 • Rotation cylinder(s)

86 • Jib lift cylinder(s)

87 • Jib extension cylinder(s)

88 • Other (per customer requirements)

Q 89 Winch Winch, sheaves and drums for damage, abnormal wear, abrasions

and other irregularities.

Q 90 Hyd Filters Hydraulic filters for replacement per maintenance schedule.

A 91 Daily All daily inspection items.

A 92 Monthly All monthly inspection items.

A 93 Quarterly All quarterly inspection items.

A 94 Hyd Sys Hydraulic fluid change per maintenance schedule.

A 95 Controls Control valve calibration for correct pressure & relief valve settings.

A 96 Valves Safety valve calibration for correct pressure & relief valve settings.

A 97 Valves Valves for failure to maintain correct settings.

A 98 Rotation Sys Rotation drive system for proper backlash clearance & abnormal wear,

deformation and cracks.

A 99 Lubrication Gear oil change in rotation drive system per maintenance schedule.

A 100 Hardware Check tightness of all fasteners and bolts, using torque specifications

on component drawings or torque chart.

A 101 Wear Pads Wear pads for excessive wear.

A 102 Loadline Loadline for proper attachment to drum.

Loading...

Loading...