sales@romanoff.com | www.romanoff.com

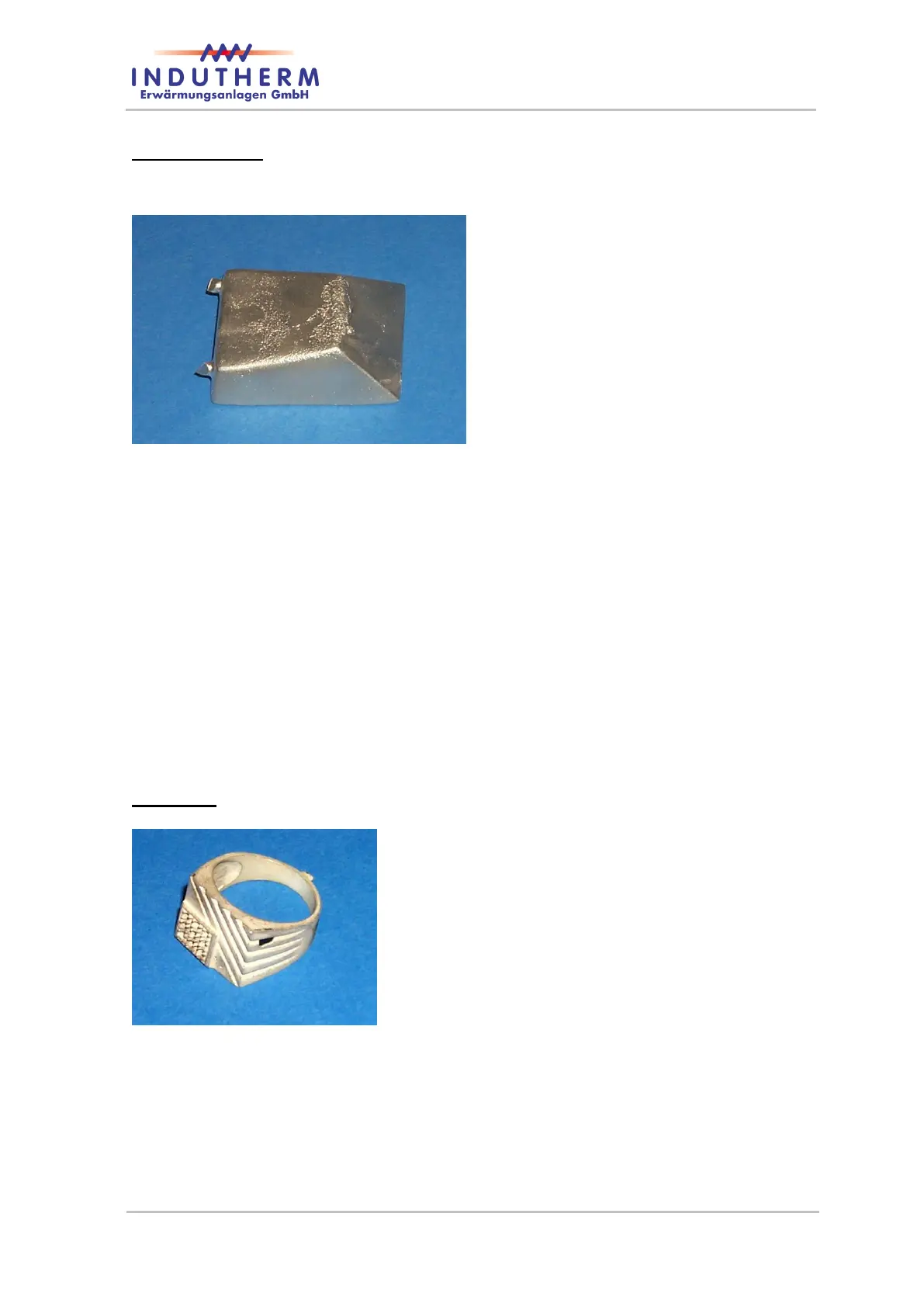

Rough Surfaces

Figure 24: rough surfaces

Use less release agent on the rubbers.

This can be caused by excess of tal-

cum. Use only a trace of talcum. Never

use silicon spray.

De-wax temperature too hot.

Do not exceed 150 ºC during de-wax.

Steam de-waxed for too long.

Steam, de-wax for a maximum of 1

hour. Steam will erode surface of the in-

vestment.

Leave flask for at least 1 hour to

achieve maximum strength before de-

waxing.

Flasks overheated during burn out.

Ensure maximum burn out temperature

does not exceed 730 ºC.

Reduce casting temperature.

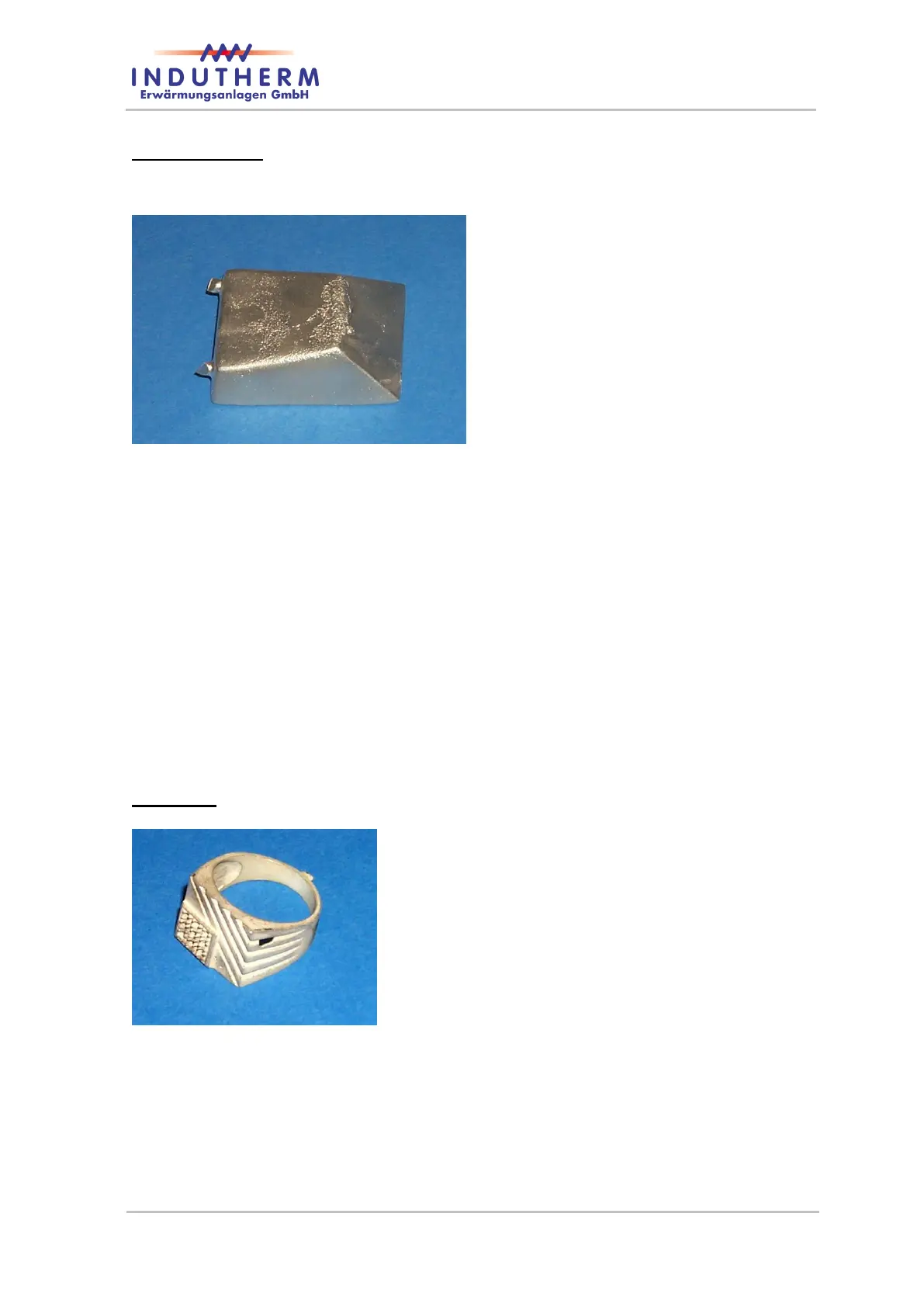

Inclusions

Figure 25: inclusions

Eliminate sharp corners in sprue system.

Replace crucible. Do not used old, disintegrating cruci-

bles.

Do not use more than 50 % recycled alloy and ensure it

is clean.

Flasks overheated dur-

ing burn out.

Ensure maximum burn out temperature does not ex-

ceed 730 ºC.

Loading...

Loading...