44

Appendix I

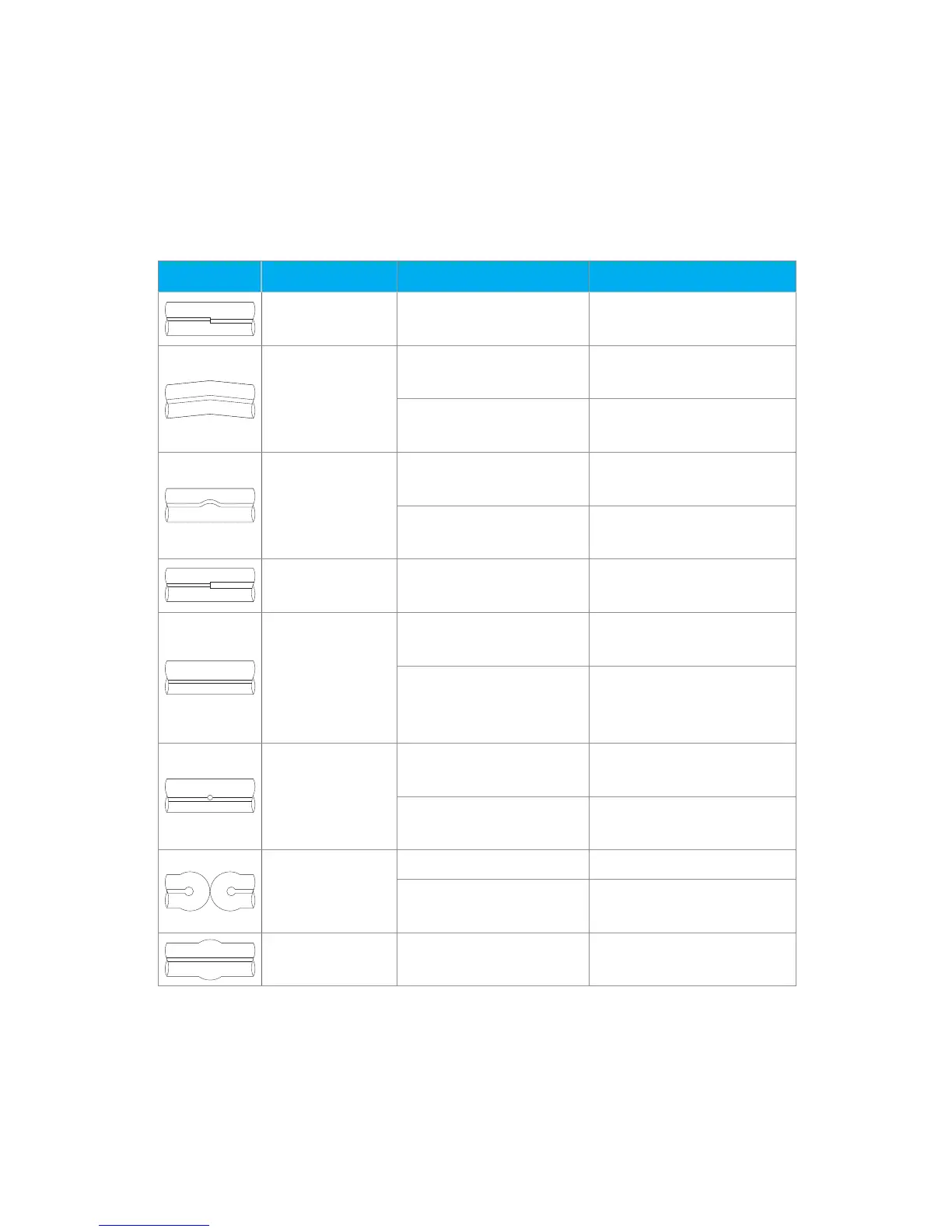

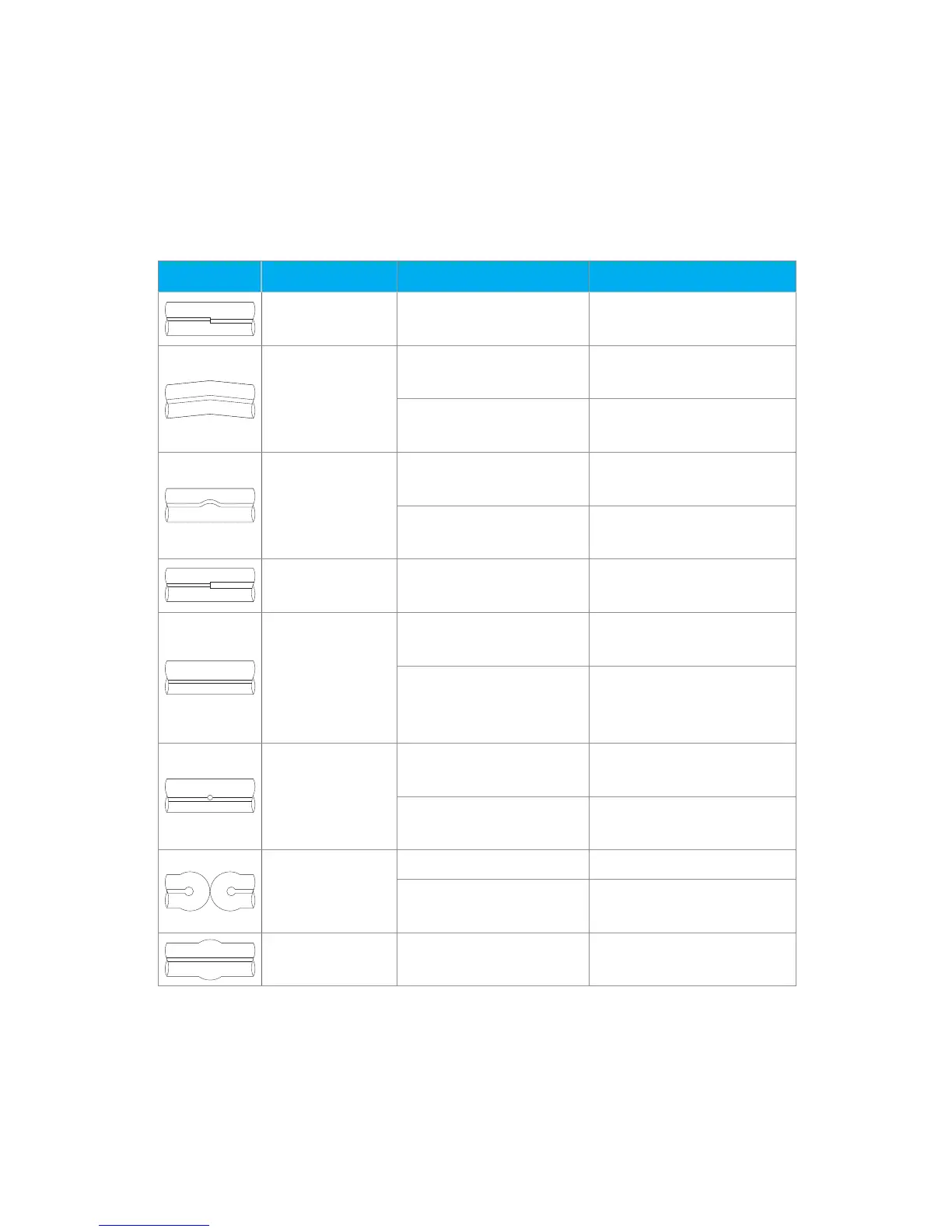

Reasons for high splice loss and solutions

Symptom Name Reason Solution

Core Axial Offset

Dust on V-groove or ber

holder.

Clean V-groove and ber

holder.

Core Angle Error

Dust on V-groove or ber

holder.

Clean V-groove and ber

holder.

Bad ber end-face quality. Check if ber cleaver is

well-conditioned.

Core Curve

Bad ber end-face quality. Check if ber cleaver is

well-conditioned.

Prefuse power is too low or

prefuse time is too short.

Increase [Preheat Arc Value]

and/or [Preheat Arc Time].

MFD Mismatch

Arc power is too low. Increase [Arc Power] and/or

[Arc Time].

Combustion

Bad ber end-face quality. Check if ber cleaver is

well-conditioned.

Dust still presents after

cleaning ber or cleaning

arc.

Clean ber thoroughly or

increase [Clean Arc Time].

Bubbles

Bad ber end-face quality. Check if ber cleaver is

well-conditioned.

Prefuse power is too low or

prefuse time is too short.

Increase [Preheat Arc Value]

and/or [Preheat Arc Time].

Separation

Fiber propelling is too less. Perform [Motor Calibration].

Prefuse power is too high

or prefuse time is too long.

Decrease [Preheat Arc Value]

and/or [Preheat Arc Time].

Fat

Fiber propelling is too

much.

Decrease [Overlap] and

perform [Motor Calibration].

Loading...

Loading...