Chapter: Assemble the load string

76 M10-17410-EN

• Make sure that the load cell is verified for the range of force that you anticipate for

your testing

• If there is a choice between two different load cells because of overlapping ranges:

• select a higher capacity load cell when you require minimum deflection of the

load cell

• select a lower capacity load cell when you require maximum long term balance

or stability

If you don’t know the tensile strength of the material, refer to a Properties of Materials

handbook to obtain an approximate strength. To calculate the tensile strength in force

units for a specimen, use the following equation:

tensile strength x cross-sectional area

For example, for a standard ASTM tensile specimen (0.502 in wide, 0.125 in thick)

made with a material of tensile strength 5200 psi (from Materials Handbook) perform

the following calculation:

5200 x 0.502 x 0.125 = 328 lbf

This produces a recommendation of the 5 kN (1000 lb, 500kg) capacity load cell.

If you cannot determine an approximate value of tensile strength, use the highest

capacity load cell rated for the frame. Perform a preliminary test at a very slow speed to

obtain the load range required. You can then determine if a lower capacity load cell can

provide improved resolution.

Table 8 on page 76 and Table 9 on page 77 list the load cells that are recommended

for use with these frames.

If you have a load cell that is not listed, contact Instron for advice on compatibility and

adapters that may be available for your load cell.

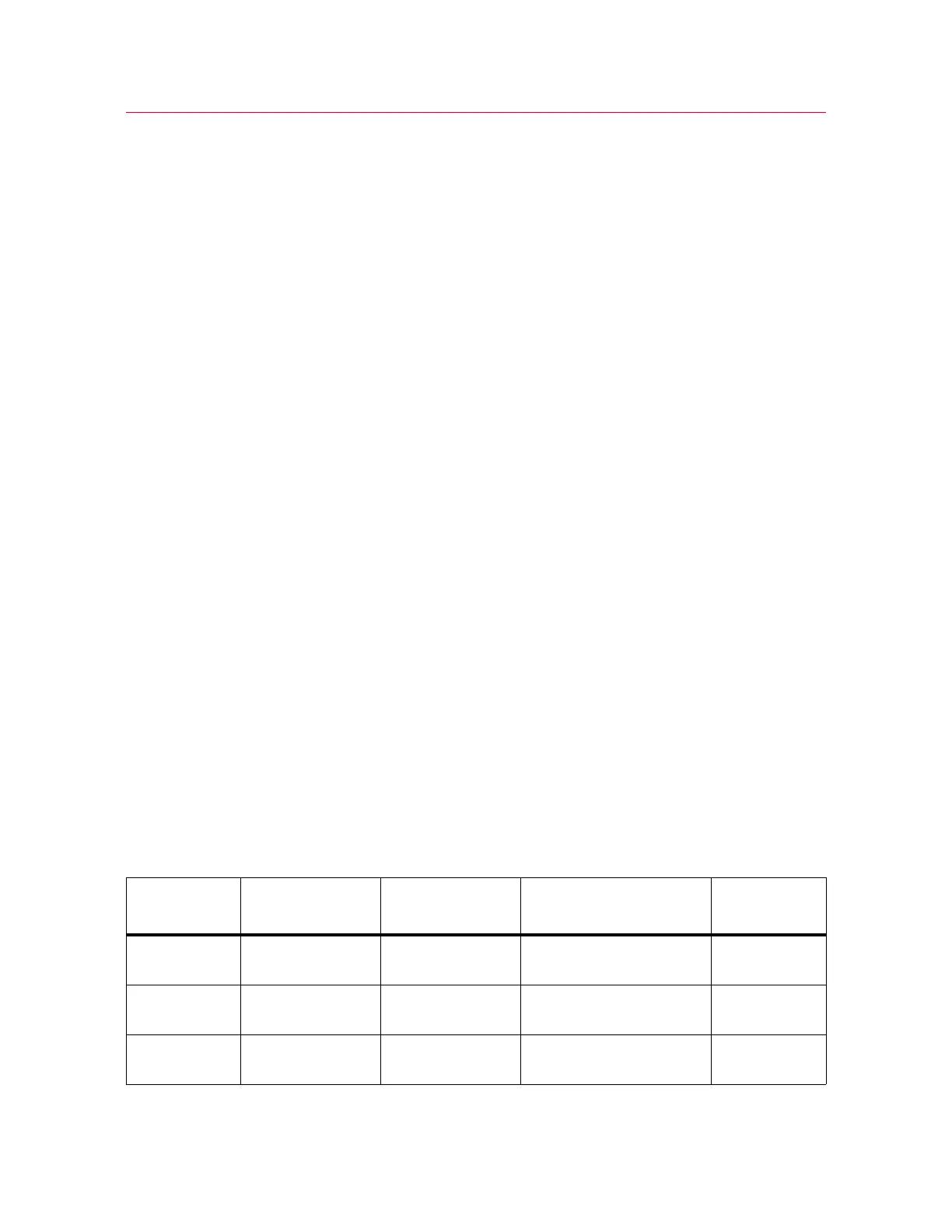

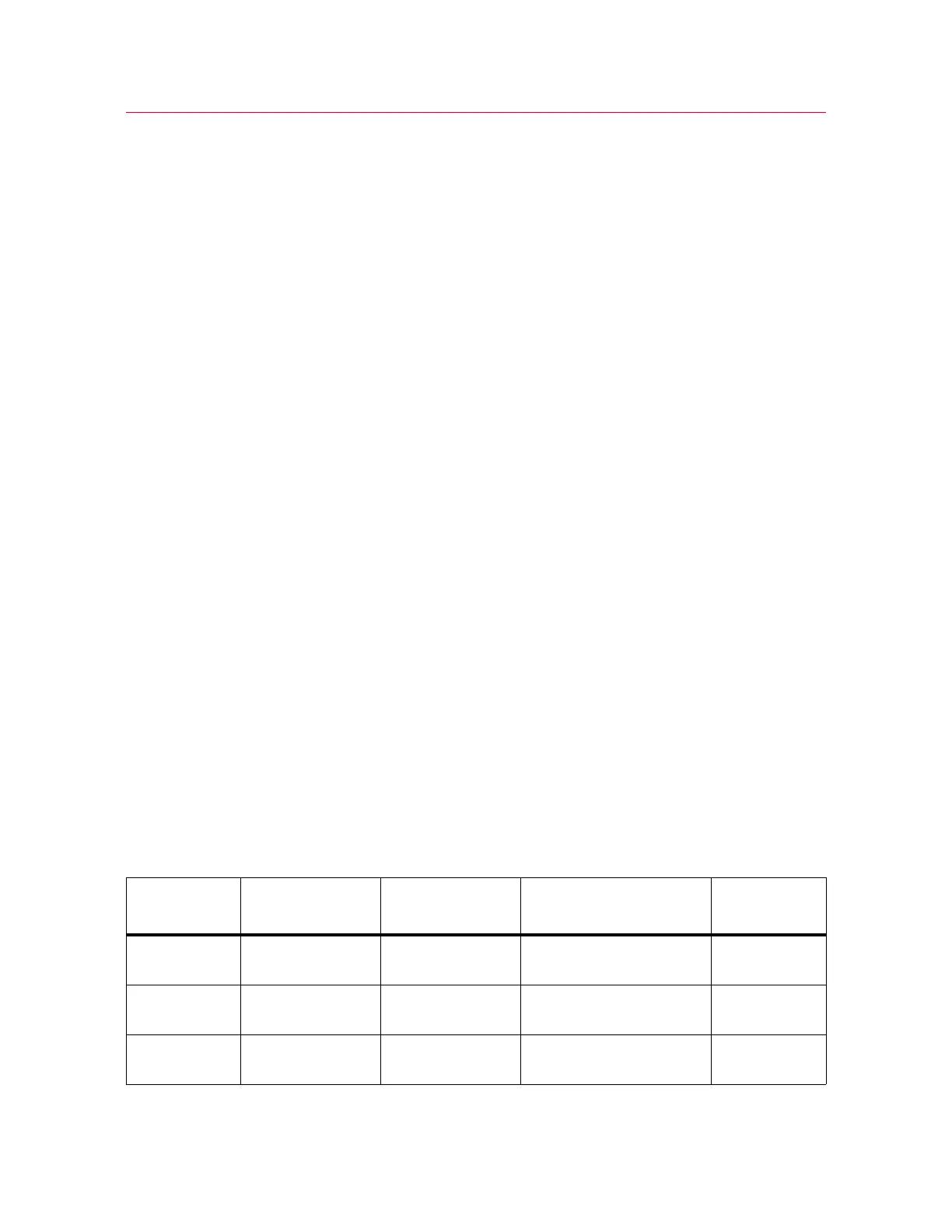

Table 8. 2530 Series

Catalog no.

Capacity

N (lbf)

Effective length

mm (in) Mechanical fitting Interface size

2530-5N 5 N (1) 48 (1.89) 2.5 mm clevis pin

and 6 mm clevis pin

OOf

Of

2530-10N 10 N (2.25) 48 (1.89) 2.5 mm clevis pin

and 6 mm clevis pin

OOf

Of

2530-50N 50 N (11) 48 (1.89) 2.5 mm clevis pin

and 6 mm clevis pin

OOf

Of

Loading...

Loading...