Chapter: Lifting and handling

54 M10-17416-EN

Unpack dual column frames

Before moving the load frame, review the following sections:

• “Site requirements” on page 25.

• “Transport dual column frames” on page 55.

1. Move the load frame, still in the shipping material, to its final location within your

building. Use a forklift (or crane) to transport the frame from the shipping dock to the

final location. Unpack the load frame after it has been moved to its final location.

After unpacking the load frame, it may be necessary to position the frame into its

operating location. Do not remove the wooden skid until you decide which method

will be used to move the frame to its operating location. The skid is required if you

choose to lift the frame from under the base.

2. Remove the shipping material, leaving the load frame fastened to the shipping skid.

3. Remove the shrink wrap vapor barrier encasing the load frame.

4. Use the packing list to inventory all the boxed items. Some accessories may be in the

container with the load frame or may be packaged separately.

a Do not open any of the packing boxes until the Instron service engineer arrives to

install your testing system. The packing list indicates the total number of boxes

that are included in the shipment. Count the number of boxes you received to

make sure you have the correct number of boxes. This ensures that no parts are

lost prior to installation.

b Do not disassemble or remove any components or parts from any Instron frame

or accessory.

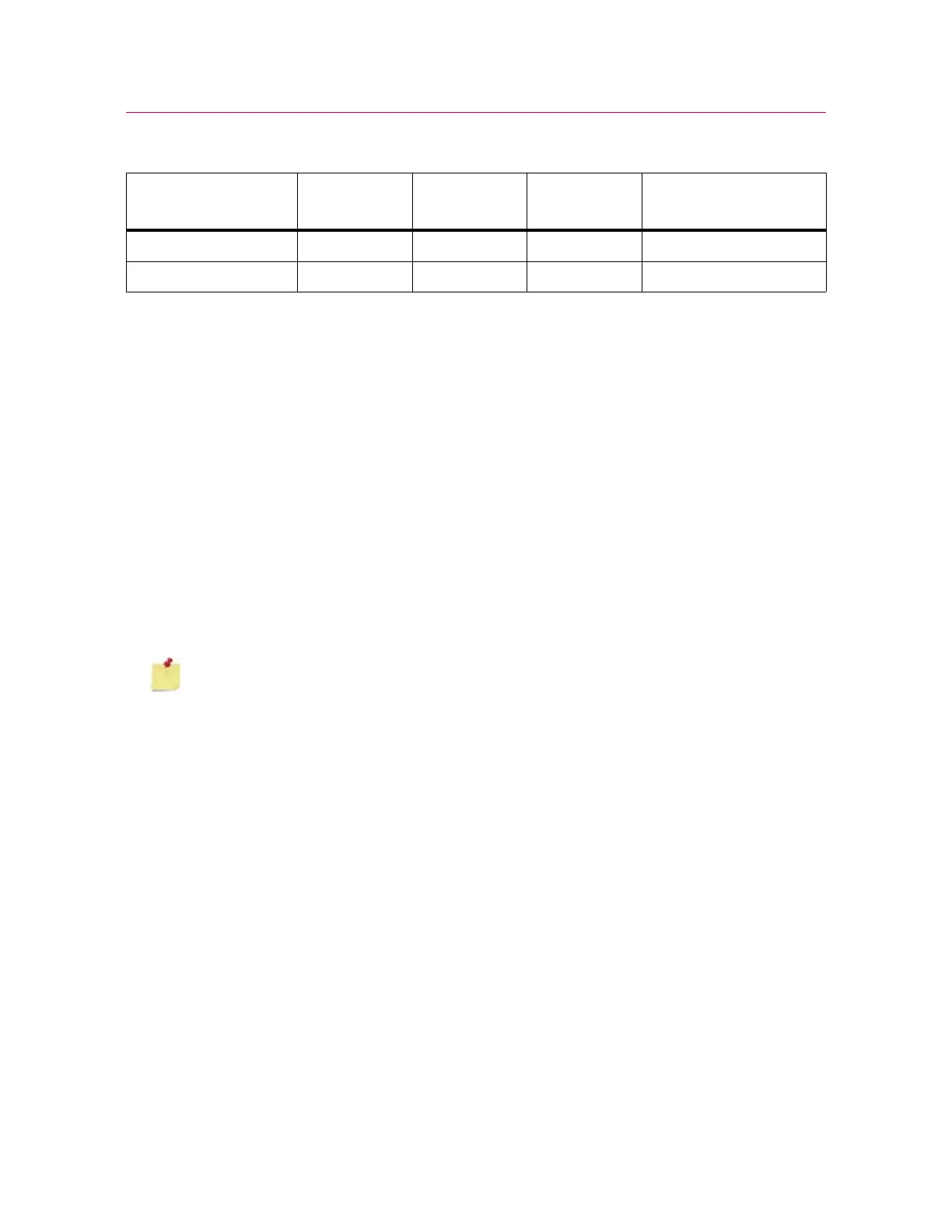

Table 13. Packaged dimensions and weights

Configuration

Length mm

(in) Width mm (in)

Height

1

mm

(in) Packaged weight

2

kg (lb)

Standard height 864 (34) 1168 (46) 1905 (75) 140 - 455 (308 - 1000)

Extra height 864 (34) 1168 (46) 2337 (92) 155 - 455 (341 - 1000)

1. This dimension is the maximum height possible. Depending on the contents, the packaging height may

be reduced.

2. This value is a range and varies with the number of accessories purchased and shipped with the

system.

Loading...

Loading...