21

Version 2.1 (08/2013) en

Translation of the original instructions

RollerDrive EC310

Assembly

Inserting the idler shaft The type of axis dictates how the idler shaft is inserted in the conveyor frame.

The spring-loaded shaft is simplest to install.

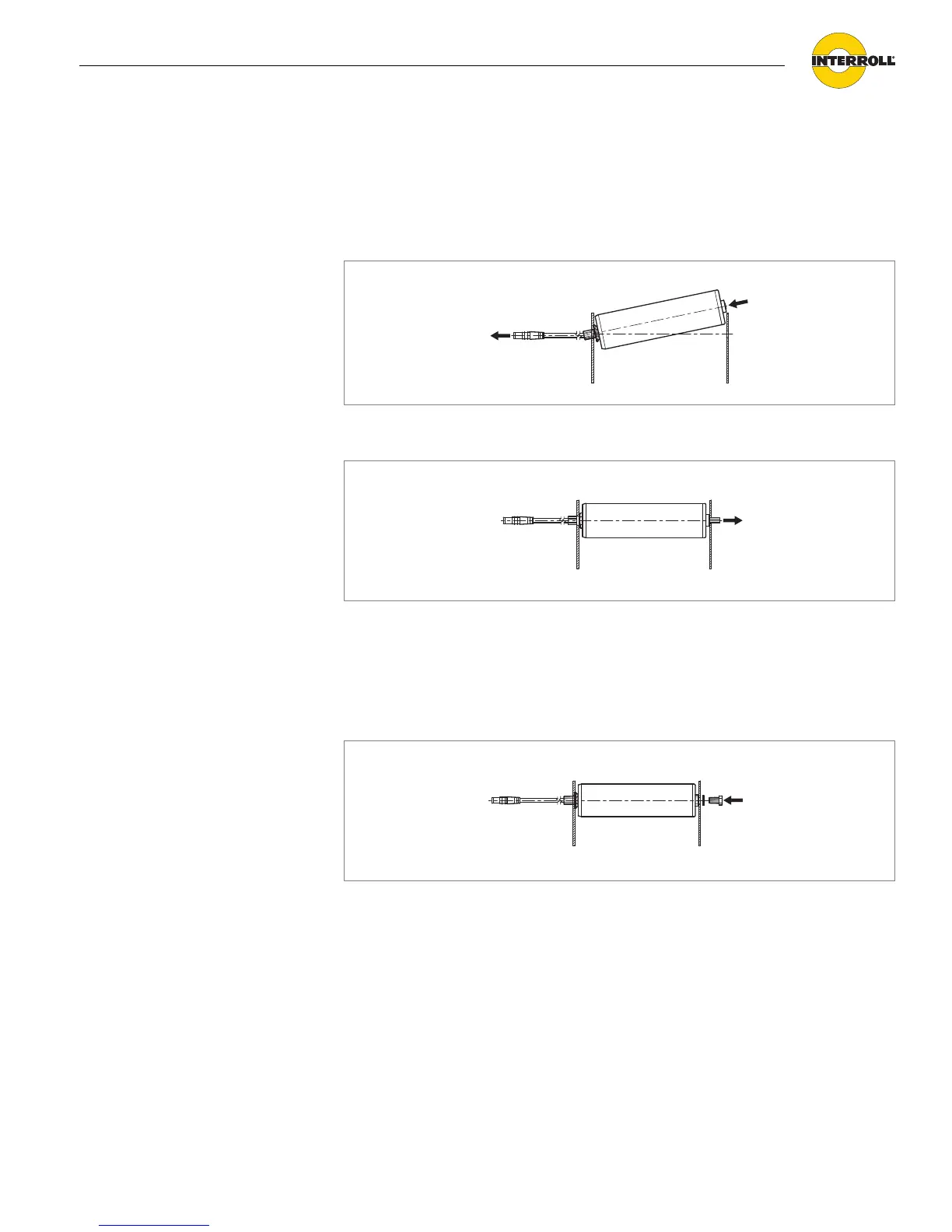

Inserting the spring-loaded hexagonal shaft

Push the spring-loaded shaft inwards and align the shaft with the hole in the

conveyor frame.

Release the spring-loaded hexagonal shaft and allow it to pop into the hole in

the frame.

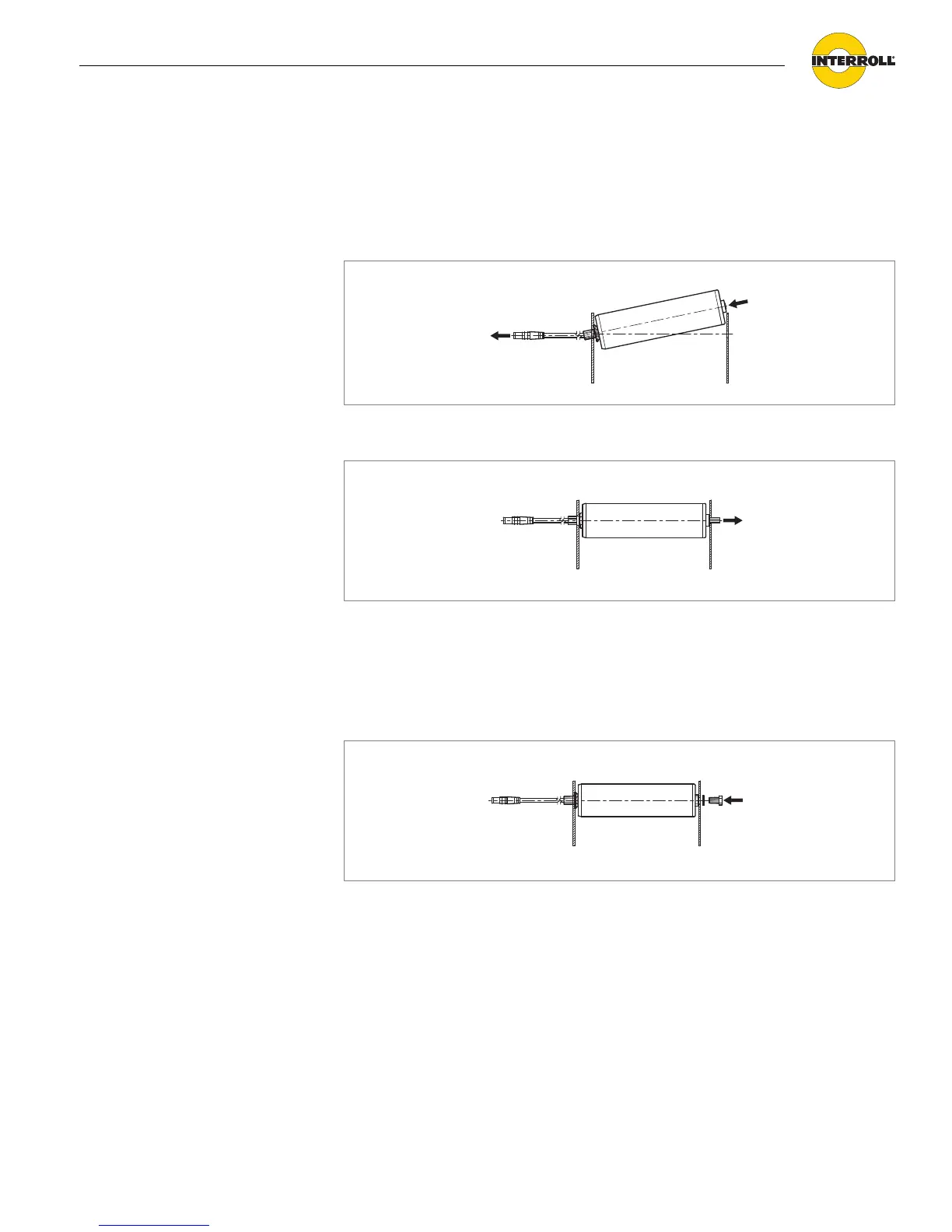

Inserting the female thread shaft pin

Place a split washer onto a M8 x 20 bolt.

Align the RollerDrive with the hole in the conveyor frame and insert the M8

bolt and split washer into the shaft. Use a wrench to prevent the shaft pin from

turning (width across flats AF 13 mm or AF 19 mm, depending on the shaft pin

type, see "Arrangement of Round Belt Grooves", page 16).

Use a torque wrench to tighten the bolt with 20 Nm (177 in/lbf) until the split

washer is completely compressed.

Loading...

Loading...