Page 30

venting system).

If the existing venting system is a horizontal run, the

slope of that system will need to be changed. As

installed, that system required a downward slope of

¼” per foot toward the outside wall. The venting

system for FT boiler requires a slope of 3/8” per foot

back toward the boiler so that condensate will drain

back to the boiler and be eliminated. To change the

slope, the vent pipe hangers will need to be adjusted

or replaced.

The centerline of the ue on the FT boiler is 3.9” (99

mm) from the back of the boiler cabinet. The centerline

of the ue on the existing boiler is 9” (229 mm) from

the back of the boiler cabinet. If the FT boiler can be

installed so that its cabinet back is 5” (127 mm) further

forward from the back wall than the existing boiler,

then the FT boiler vent and the venting system will be

in alignment. If, however, the boiler location for the FT

boiler, with respect to the back wall, cannot be

changed, 45° oset ttings will be required to bring the

centerline of the FT vent forward to align with the

existing vent assembly.

The FT boiler has separate Combustion Air and Vent

connections. Using the Parts Kits indicated in the

following instructions, it can be connected with a PP

Concentric Vent System.

If this 5" oset in the venting system is required, it can

be achieved in 2 ways.

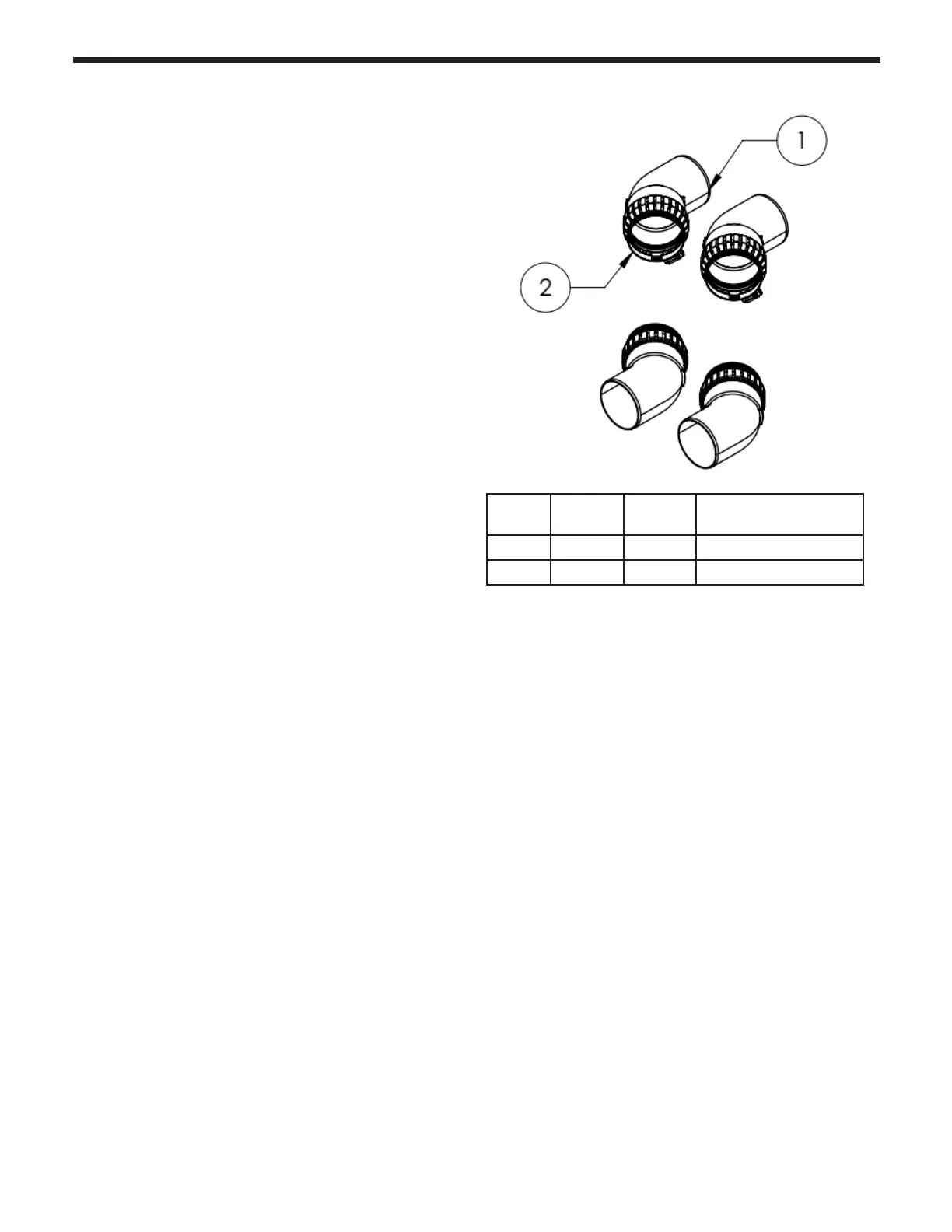

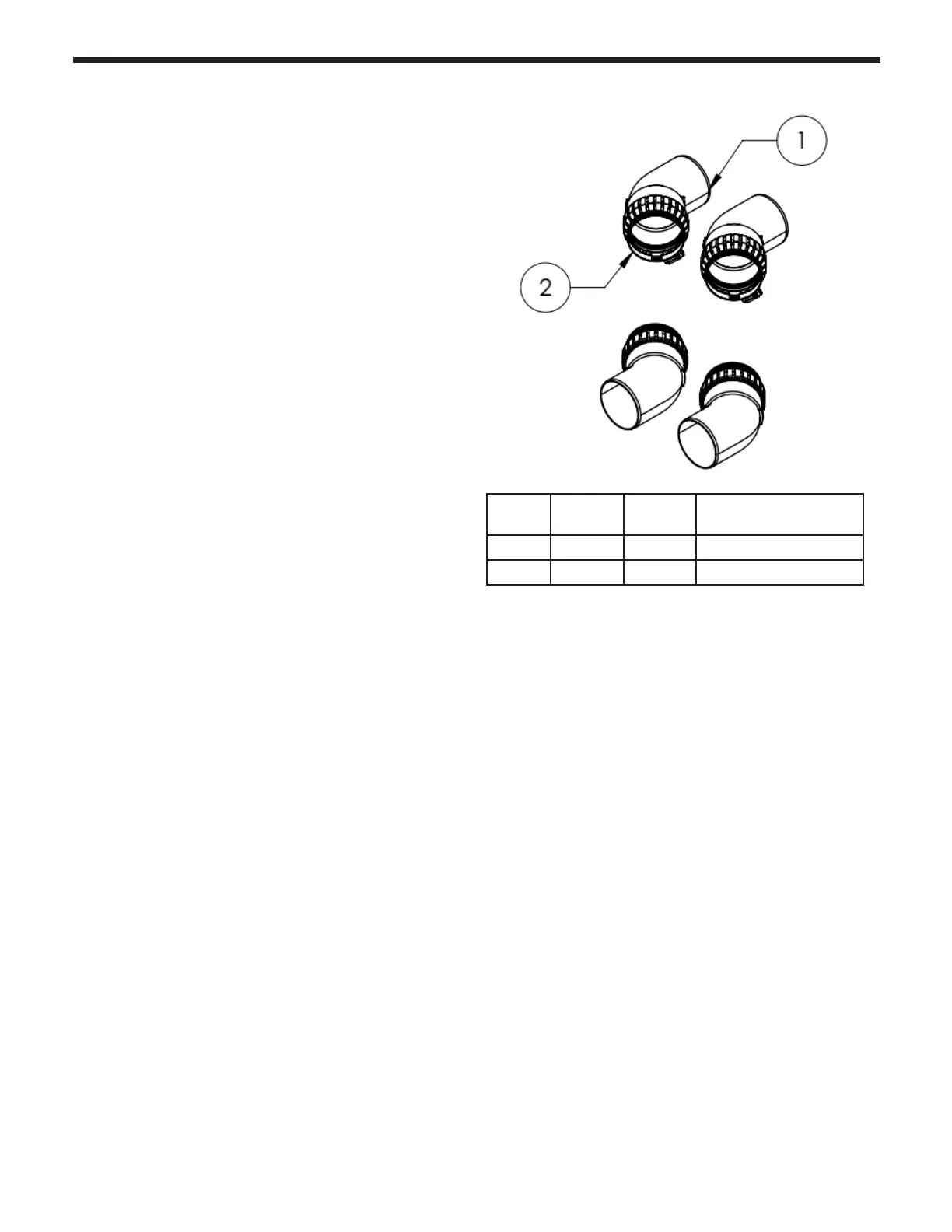

Option 1:

Assemble the elbows in an FT3001 Elbow

Kit to form two oset assemblies. Ensure that the

elbows bottom out and tighten the clamps.

Option 2:

Use 2 45° Duravent concentric elbows

(3PPC-E45) and install them in o-set fashion into the

concentric vention as described below.

Venting Assembly Process:

1)

Start the installation by installing only the 2

stainless to PP adapters of the P/N FT3002 Stub Out

Kit, directly in the FT boiler Combustion Air and Vent

sockets. Ensure that all connections bottom out and

tighten the clamps on the boiler vent connectors.

2)

If the above mentioned 5" oset is required, install

now the 2 pre-assembled o-set assemblies into each

stainless to PP adaptor. Then install the 2 PP lengths

into the Stub-out kit (FT3002)(Option 1 solution for

o-set).

Note:

Do not overtighten the connections until the

entire system is put together.

3)

If FT3001 Elbow kit is not required, the complete

Stub-out kit (FT3002) can be installed or o-set option

2 is selected, the length of the 2 PP portions can be

shortened; make sure to cut the same length from

each pipe. Do not cut more that 6-1/2" from each

pipe.

Assemble the parts in the following order:

4)

Insert the 3" stainless steel to PP adapters into the

2 3" vent connections on top of the FT Boiler until

they bottom out into the sockets.. Moisten the seals on

the sockets to make the insertion easier and to avoid

damaging the seals. Tighten the clamps on the boiler

FT3001 Oset Kit

ITEM

NUMBER

QUANTITY PART

NUMBER

DESCRIPTION

1 4 810014537 3˝ Dia 45° Elbow - Single Wall

2 4 810014538 3˝ Dia Locking Clamp

Loading...

Loading...