Goodrive300-LIFT series inverter Commissioning guidelines

-77-

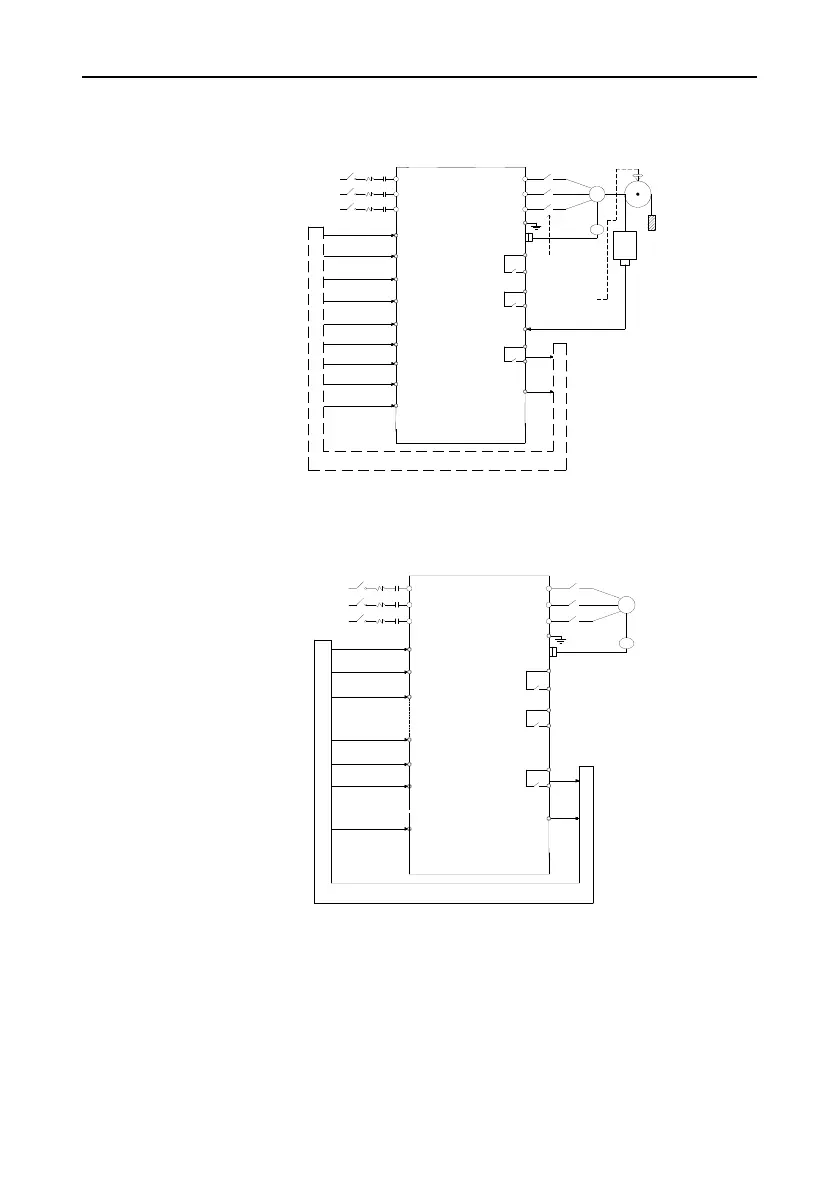

7.2 Wiring between the lift controller and inverter

7.2.1 Wiring for the multi-step speed running mode

R

S

T

S1

S2

S3

S4

S5

S6

S7

S8

HDI(S9)

W

V

U

PE

Y1

LR

EO

KM1

Maintenance

Brake feedback

Contactor feedback

Multi-step speed 3

Multi-step speed 2

Multi-step speed 1

Enable

Down

Up

Fault output

RO1

RO2

RO3

Weigh AI1 input

FC(brake

control)

TC(contactor

control)

Car

PG

M

KM2

GD300L inverter

special for lifts

3PH

380V-15%

~440V+15%

50/60Hz

Lift controller

FWD

REV

ENA

MS1

MS2

MS3

TB

FB

EXM

Figure 7-2 Typical wiring for the multi-step speed running mode

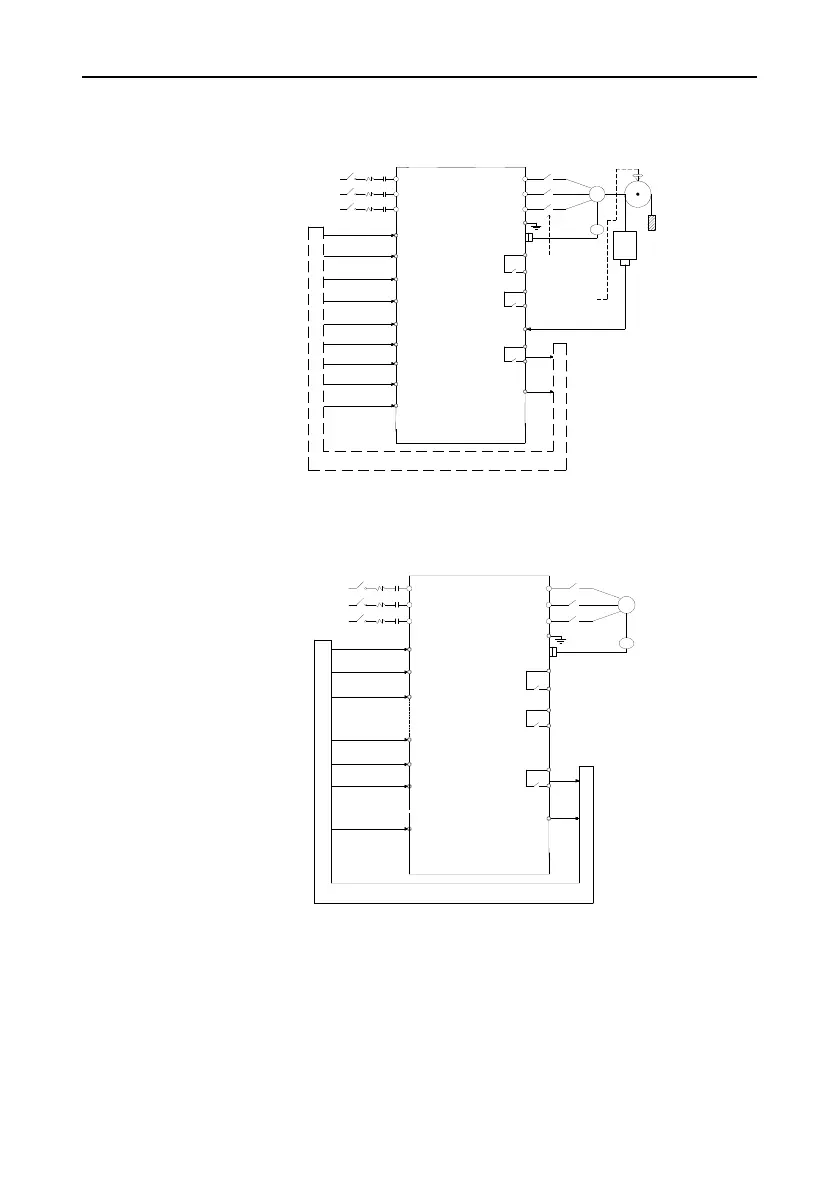

7.2.2 Wiring for the analog speed running mode

Lift controller

3PH

380V-15%

~440V+10%

50/60Hz

GD300L inverter

special for

lifts

KM2

M

PG

TC(contactor

control)

FC(brake

control)

RO3

RO2

RO1

Fault

output

Enable

Up

Down

Maintenance

Contactor feedback

Brake feedback

KM1

EO

LR

Y1

PE

U

V

W

AI1

FB

TB

EXM

REV

FWD

ENA

T

S

R

Speed command

S1

S2

S3

S7

S8

HDI(S9)

SPD

Figure 7-3 Wiring for the analog speed running mode

7.3 Setting basic parameters

After correct wiring, set application parameters as required. Pay high attention to the parameters

related to peripheral electrical wiring, such as operation mode, control mode, programmable

input/output setting, and feedback selection. Perform commissioning only after these parameters are

correctly set. The table below lists the basic parameters.

Loading...

Loading...