Goodrive300-LIFT series inverter Communication protocol

-124-

P10.01 Load compensation time 0.000~5.000s 0.400

◎

Enable non-weighing

compensation

Note: P29 group is the factory parameters which cannot be read or changed. Some parameters

cannot be changed when the inverter is in the running state and some parameters cannot be changed

in any state. The setting range, unit and relative instructions should be paid attention to when

modifying the function code parameters.

Besides, EEPROM is stocked frequently, which may shorten the usage time of EEPROM. For users,

some functions are not necessary to be stocked on the communication mode. The needs can be met

on by changing the value in RAM. Changing the high bit of the function code form 0 to 1 can also

realize the function. For example, the function code P00.07 is not stocked into EEPROM. Only by

changing the value in RAM can set the address to 8007H. This address can only be used in writing

RAM other than reading. If it is used to read, it is an invalid address.

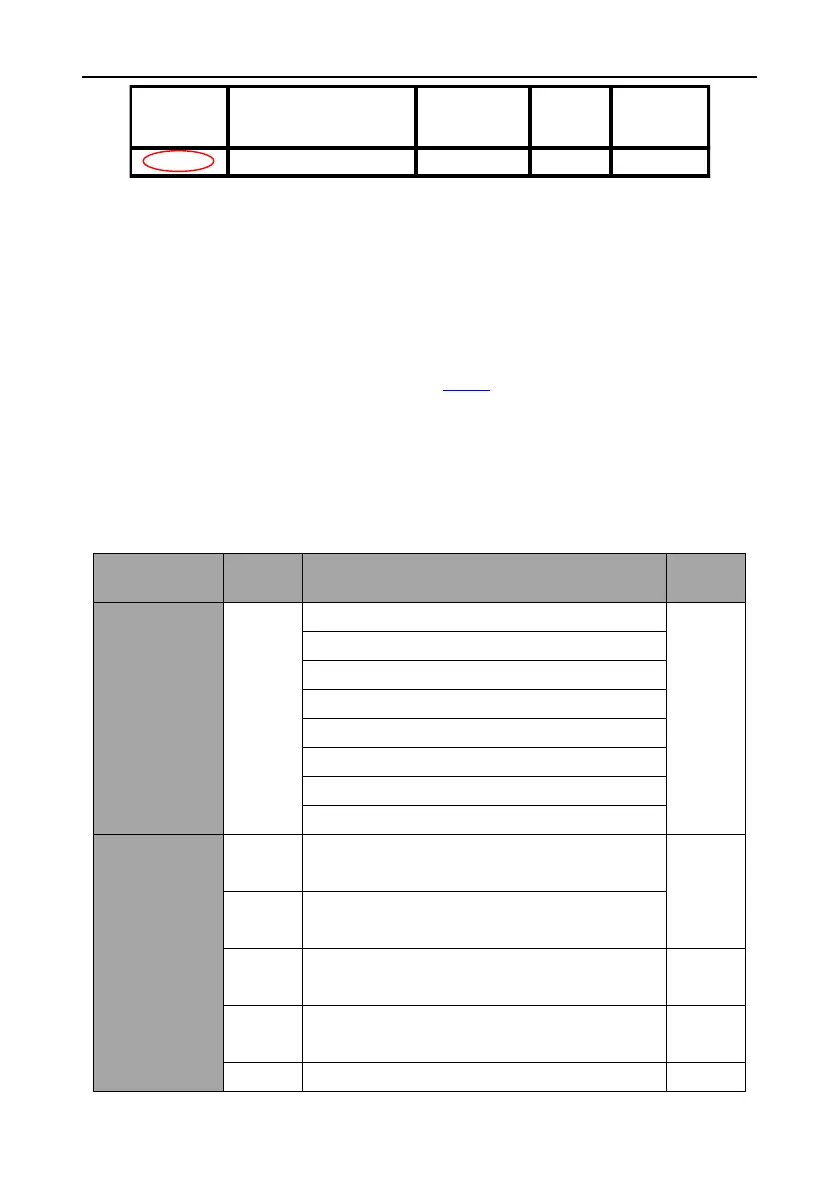

10.4.5.2 The address instruction of other function in Modbus

The master can operate on the parameters of the inverter as well as control the inverter, such as

running or stopping and monitoring the working state of the inverter.

Below is the parameter list of other functions:

Communication

control command

0006H: Coast to stop (emergency stop)

The address of

communication

setting

Communication setting frequency (0–Fmax, unit:

0.01Hz)

PID given, range (0–1000, 1000 corresponds

to100.0%)

PID feedback, range (0–1000, 1000 corresponds

to100.0%)

Torque setting value (-3000–3000, 1000 corresponds

to the 100.0% of the rated current of the motor)

The upper limit frequency setting during forward

Loading...

Loading...