i-ALERT2 Application Guide 10 of 64

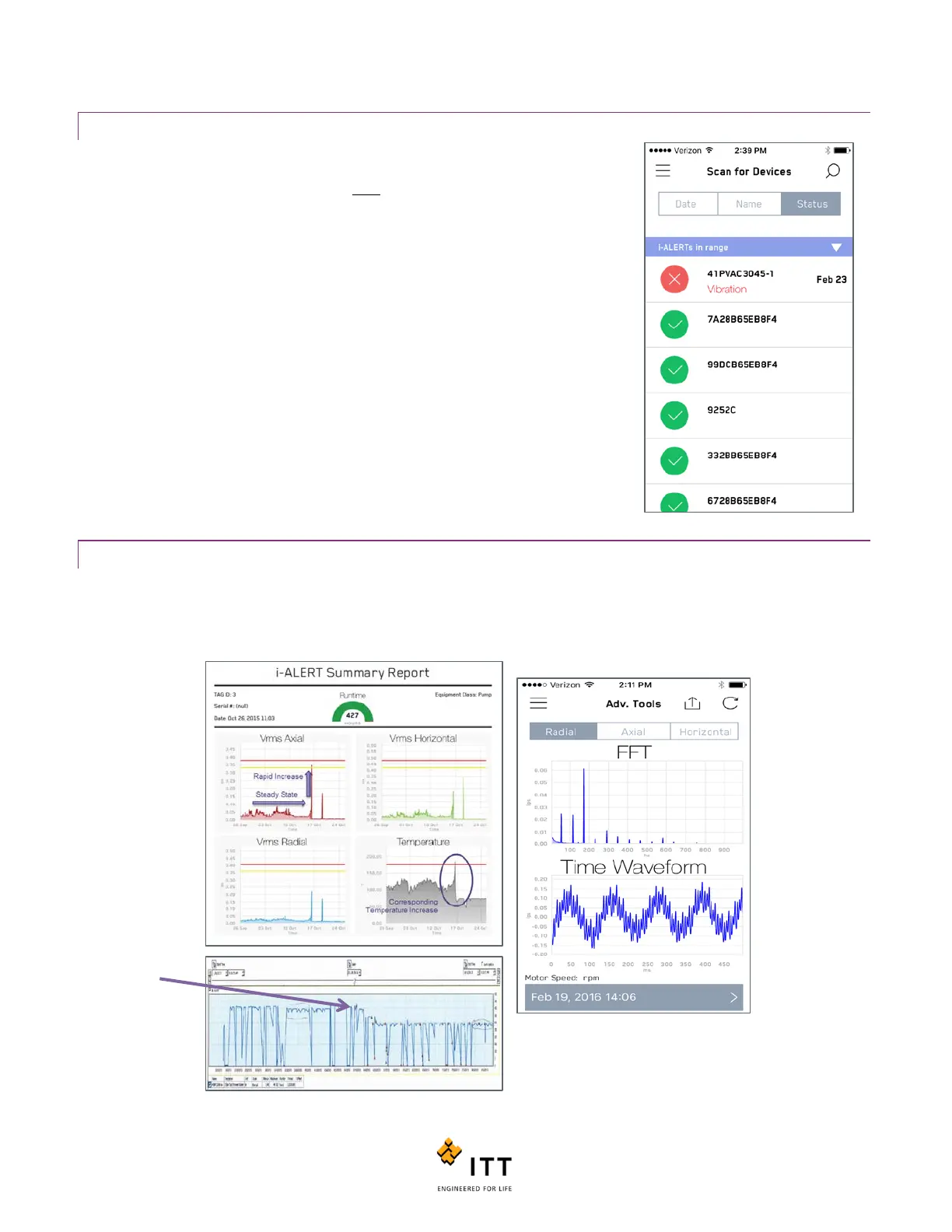

STEP 1.NOTICE: DETECTION OF PROBLEMS

Since analysis of machine problems is a time consuming process and there are many

machines in a typical plant, it is important NOT to try to analyze all machines. The

first step in an effective condition monitoring program is to identify the problem

machines. This is the purpose of the detection phase of the program. Measurements

and machines are organized into a series of logical routes and data is collected on

them in a routine manner. Route functionality is a cornerstone of the i-ALERT2

condition monitor’s value. One of the strengths of the i-ALERT2 monitor is the ability

to broadcast the machine’s condition without having to wirelessly connect to it. The

data collected is designed to indicate when a change has occurred or when a preset

limit has been exceeded. After the data has been collected, it is reviewed and

exceptions are noted and reported.

After identifying machines in need of further analysis using detection, the next step is

to determine the root cause of the problem. This is

achieved during the INVESTIGATE or ANALYSIS phase.

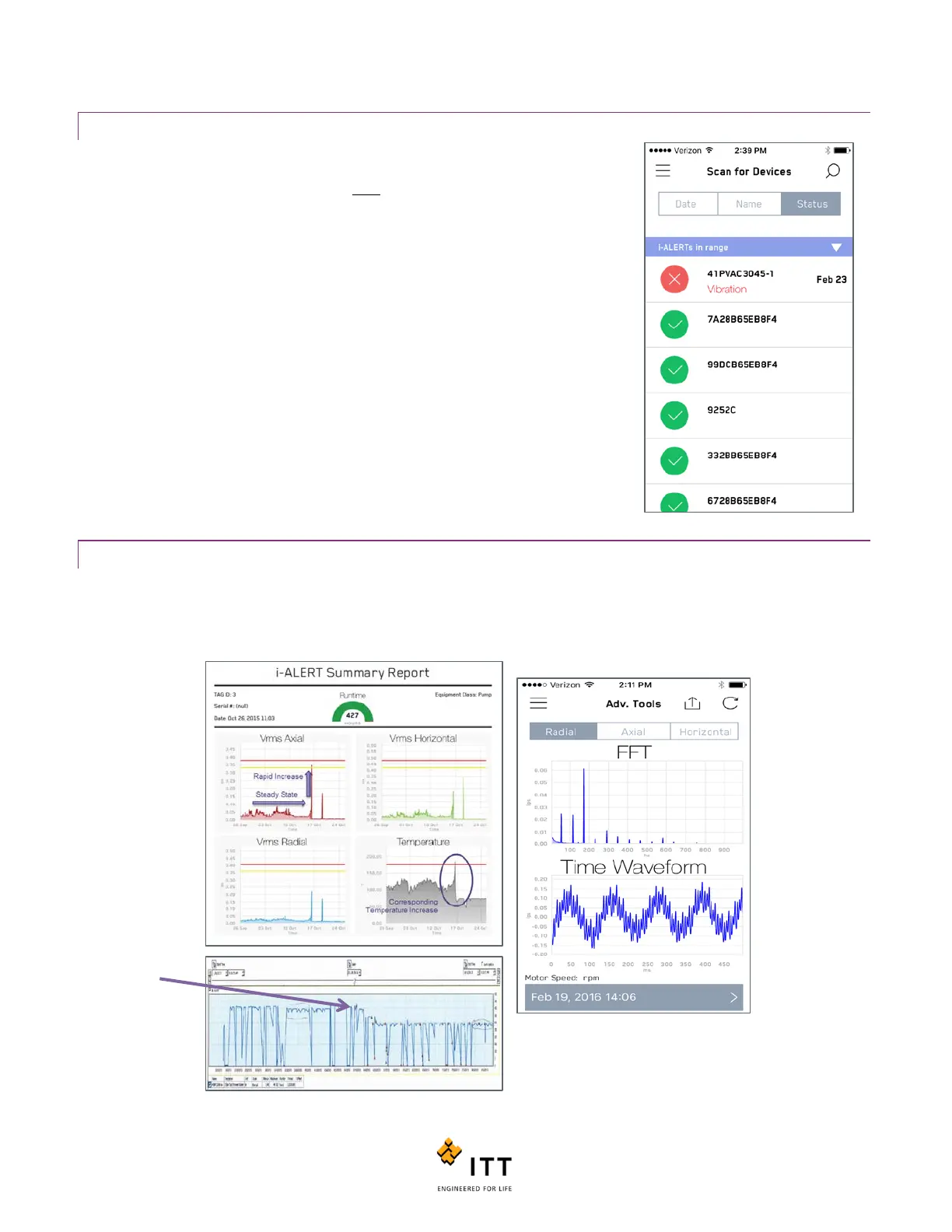

STEP 2.INVESTIGATE: ANALYZE THE PROBLEM

The analysis phase involves gathering more detailed diagnostic data which can include process conditions, flows, pressures,

FFT, TWF, Timestamps and Trend data. Performing such analysis is a time consuming process and should NOT be

attempted on all machines, only the ones that have exceeded alarm limits.

Figure 4: Simultaneously view

states of all devices in range

Process change

Figure 5: Process data related to

condition monitoring data

Loading...

Loading...