i-ALERT2 Application Guide 20 of 64

INSTALLATION BEST PRACTICES

MOUNTING LOCATIONS

GENERAL GUIDELINES

In general the ideal place to mount the i-ALERT2 device is as close as possible to the machines bearings in a place where the

LEDs can be easily observed. Since the primary function of the i-ALERT2 device is to monitor for changes in condition, it is

not critical that the device be placed in the “load zone” of the bearing. Doing so may give a more accurate amplitude

reading, but may obscure the LEDs which are used for local status indication.

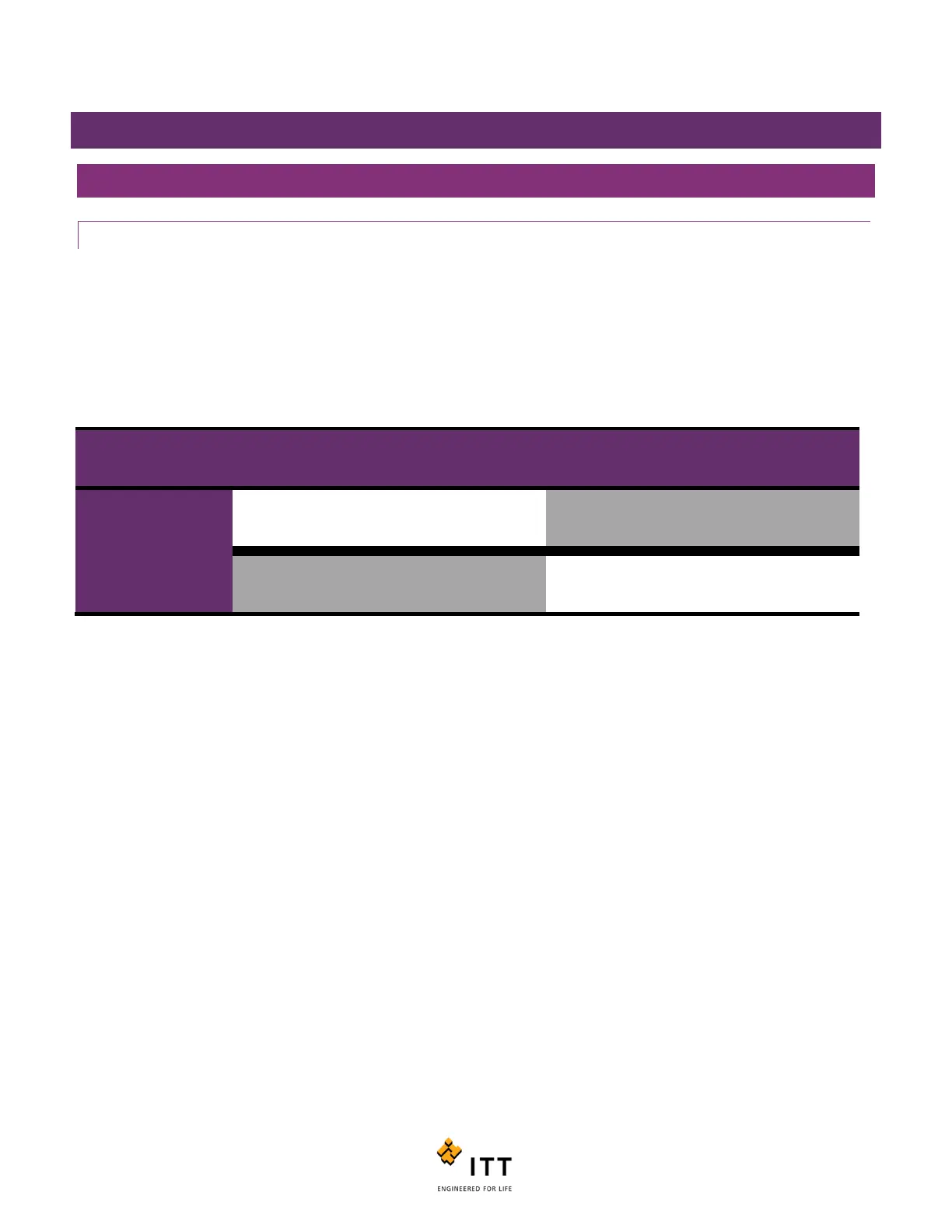

In general, a standard machine train consisting of a driver and driven piece of equipment can be monitored by 2 i-ALERT2

devices. Up to 4 monitors can be installed per machine train, one at each bearing if necessary.

Machine Type

Non-Drive End

Bearing

Drive End Bearing Drive End Bearing

Non-Drive End

Bearing

Driver Optional Recommended

Driven Machine

Recommended Optional

Figure 11: Recommended monitoring points

Loading...

Loading...