Hi-E2

Page 9

Supply Pressure Minimum Maximum

Natural Gas 5 inches WC

(125 mm WC)

10.5 inches WC

(265 mm WC)

LP Gas 11 inches WC

(280 mm WC)

14 inches WC

(350 mm WC)

Table 4. Gas Supply Pressure Requirements.

Gas piping must be large enough to provide the

required gas fl ow rate without excessive pres sure drop.

Table 5 specifi es pipe sizes which will limit pressure

drop to 0.5 In WC (125 Pa), based on the National

Fuel Gas Code, ANSI Z223.1/NFPA-54.

Model

Natural Gas LP Gas

0-50'

(0-15m)

50-100'

(15-30m)

100-200'

(30-60m)

0-80'

(0-15m)

50-100'

(15-30m)

100-200'

(30-60m)

220 1" 1-1/4" 1-1/4" 3/4" 1" 1-1/4"

350 1-1/4" 1-1/4" 1-1/2" 1" 1-1/4" 1-1/4"

Table 5. Required Gas Pipe Size.

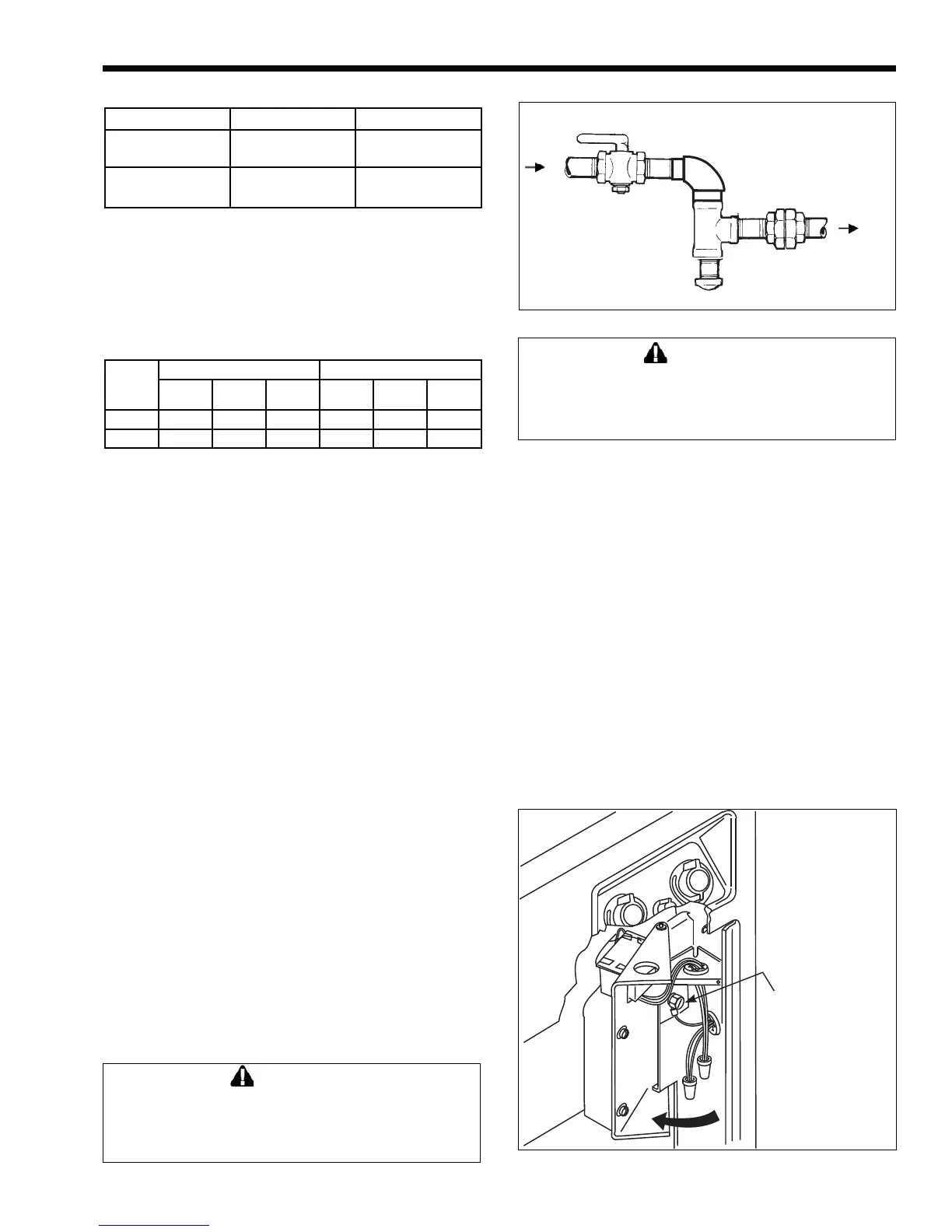

Support gas piping properly so its weight

does not bear on the heater. Install a drip leg, a non-

restrictive shutoff valve and a union on the gas supply

line outside of the heater (see Figure 14).

Before operating the heater, test the gas supply

system, including all connections, for leaks using a

soap solution. Do not use a fl ame or any ignition

source for leak detection. Dis con nect the heater and its

individual gas shutoff valve during pressure testing if

the test pressure is higher than 1/2 psig (3.34 kPa). If

the pres sure is 1/2 psig (3.45 kPa) or lower, close the

manual valve on the heater gas control during testing.

When the heater is started, check the supply

pressure to verify that it is adequate during heater

operation. Undersize piping, a restrictive fi tting or an

undersize gas meter can cause low operating pressure.

High Elevation

To assure good combustion and general

op er a tion, gas appliances are normally de-rated when

installed at high elevation. This is not necessary

with the Hi-E

2 because it has a special venturi-type

combustion system which self-com pen sates for

changes in barometric pressure. Air fl ow through the

venturi pulls the correct fl ow of gas into the burner

regardless of air density. Good quality combustion and

high effi ciency are assured without special adjustment

or changes to the heater.

2J. Electric Wiring

WARNING

ELECTRICAL SHOCK HAZARD. This heater

contains wiring that carries high voltage. Con-

tact with these wires may result in severe injury

or death.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

2J-1. Electrical Power

Electrical wiring must be in accordance with the

latest edition of the National Electric Code (NEC),

ANSI/National Fire Protection Association (NFPA) 70,

unless local code requirements indicate otherwise; and

in Canada with latest edition of CSA C22.1 Canadian

Electrical Code.

The Hi-E

2 requires electrical power from a 115V,

60 Hz source. Wiring connections must be made

exactly as shown in the wiring diagram (see Figure

16). Grounding must be provided as required by the

prevailing electrical code.

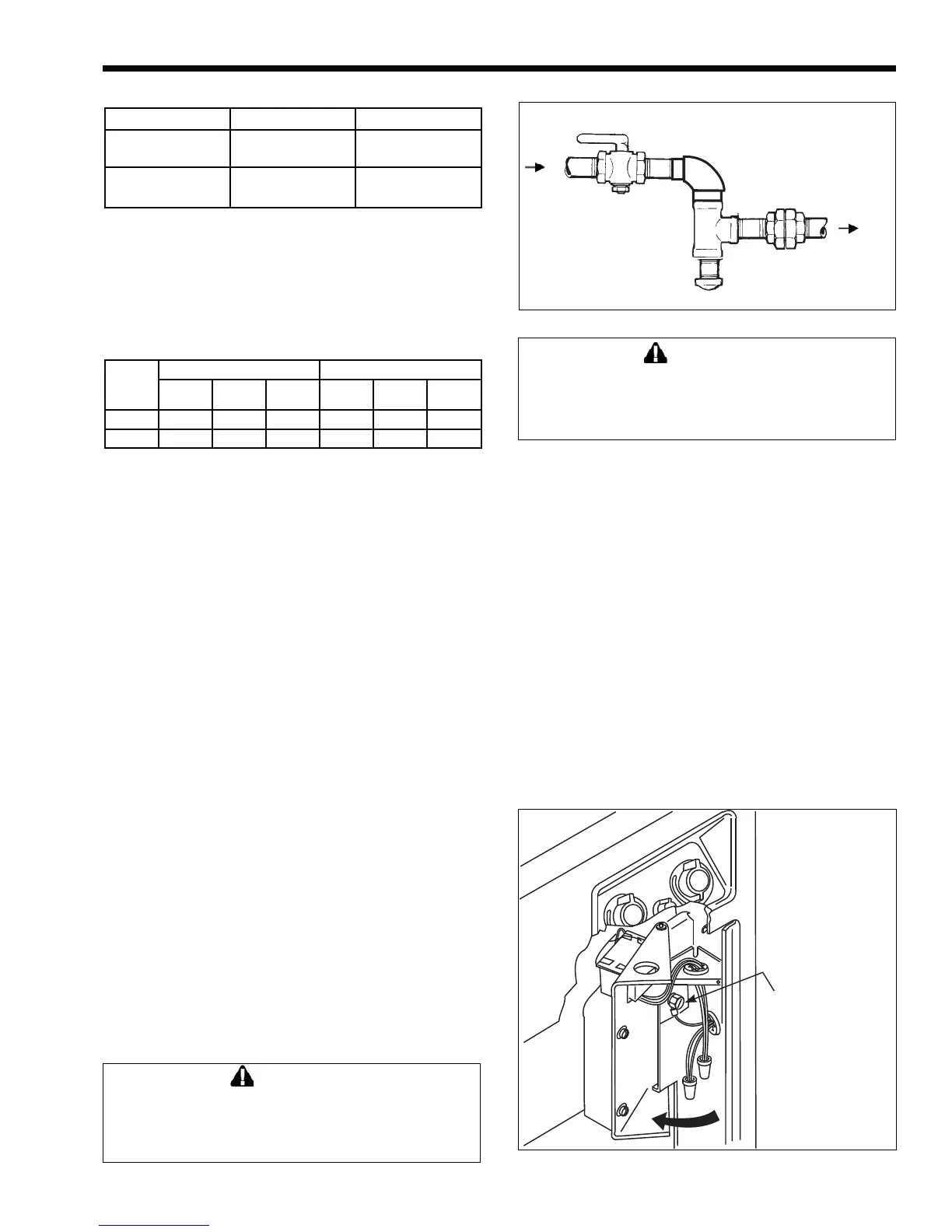

Connect wiring inside the junction box , which is

on the right side of the heater and is accessible through

the door opening. Line voltage con nec tions must be

made within this box. A labeled green grounding screw

is provided in the junction box for a ground ing wire

(see Figure 15).

Figure 14. Gas piping at heater.

To

Heater

From

Supply

Figure 15. Field wiring connections.

ATTACH GROUND-

ING WIRE TO

GREEN GROUND-

ING SCREW

Loading...

Loading...