janome.com

Page 35

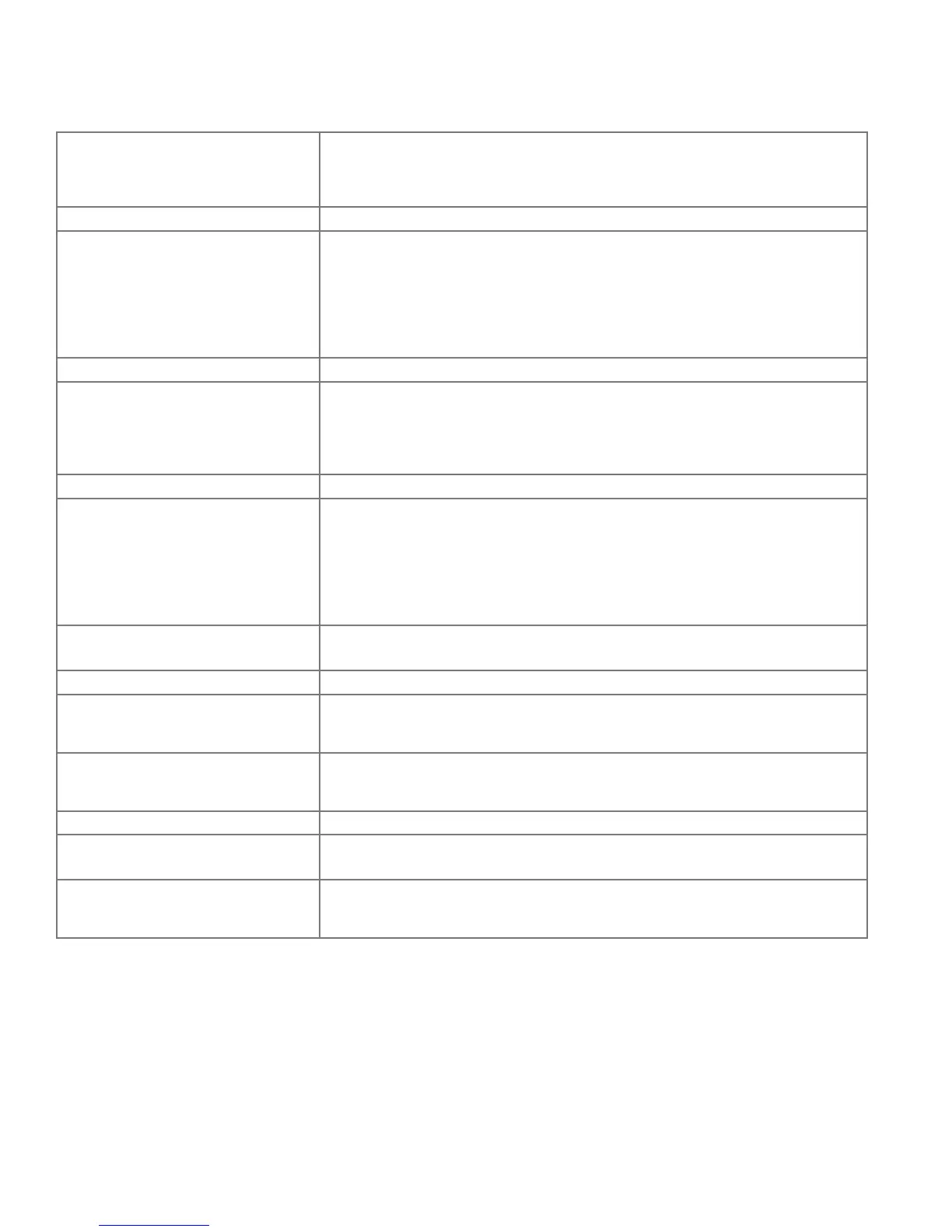

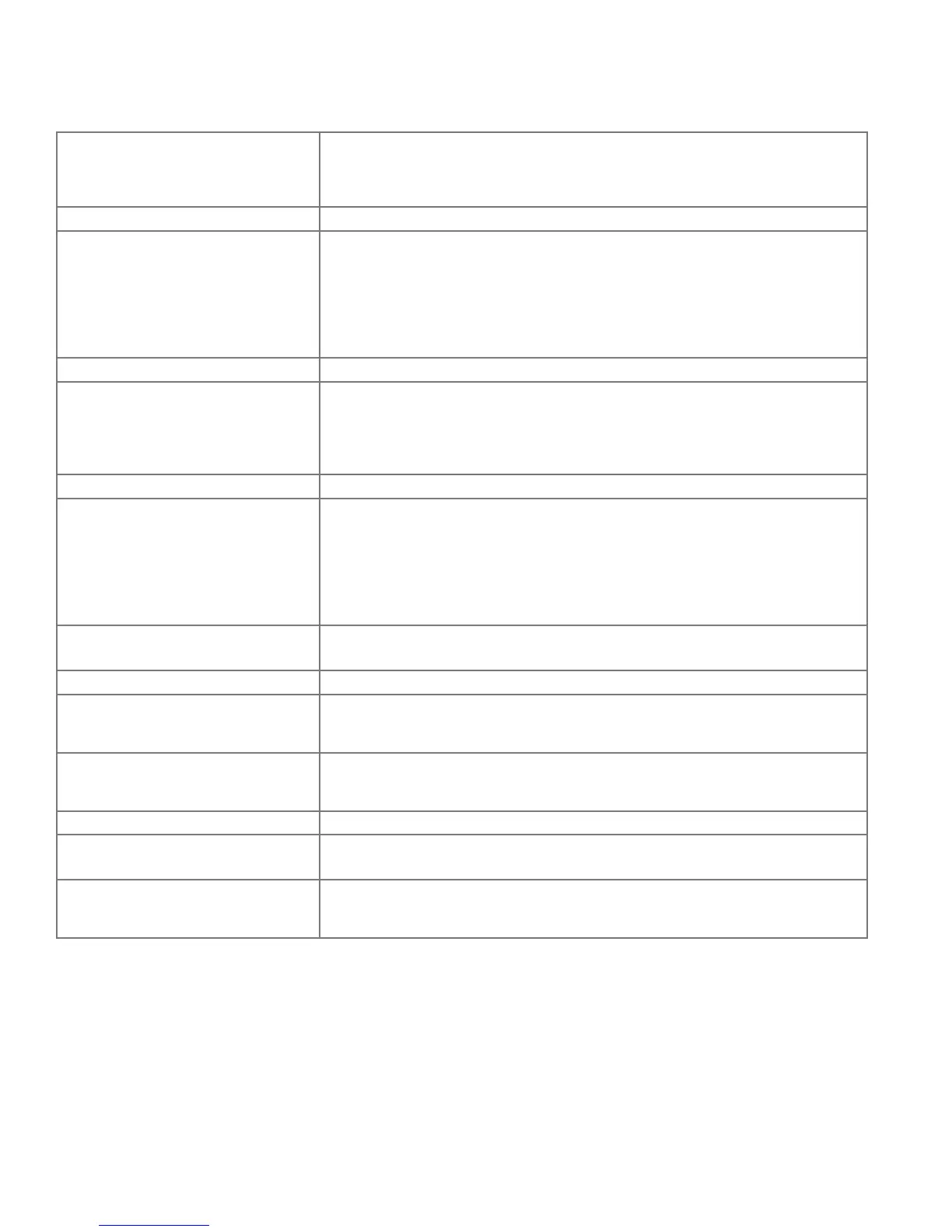

Troubleshooting

* If the troubleshooting above does not eliminate the problem, please consult an authorized Janome Quilt Maker

Pro 18 representative.

Moving the machine too fast

for needle speed selected

(Manual mode)

• Synchronize machine movement and needle speed to get roughly 8 to

10 stitches per inch. Elongated stitches are an indication of moving the

machine too fast for the current speed.

Tension is Poor Corrective Measure(s)

Lint caught under the tension

spring in the bobbin

• If using short staple threads, inexpensive, or industrial threads, or

coated threads, lint and other material will build up under the tension

spring and begin to lift the spring, reducing the spring’s ability to

compress against the thread. Insert a needle or business card under the

spring and clear out the lint. The bobbin tension will return fairly close

to its preset tension. Test the tension before quilting.

Hand Wheel Won’t Rotate Corrective Measure(s)

Thread is entangled and caught in

the hook

• Turn off the machine and unplug the machine from the electrical outlet.

Lubricate the hook, strongly turn the hand wheel clockwise and if

necessary counterclockwise several times, and then remove the thread

caught in the hook.

Thread Nests Under Quilt Corrective Measure(s)

Not enough tension on

top thread

• Check that the machine is threaded correctly. Make certain that the

thread is flossed snugly in place between the two tension discs. If

the machine is threaded correctly, tighten top tension by rotating the

tension knob clockwise. (For more information about adjusting tension,

see Bobbin and Bobbin Tension and Top Thread Tension in the Using

Your Machine section of this manual.)

Improper threading

• Refer to threading diagram and threading instructions.

Hard to Guide Machine Corrective Measure(s)

Carriage wheels not centered

on track

• Center the carriage wheels on top of the continuous track. Check that

the machine carriage has not jumped the track.

Thread caught in wheels • Remove all thread or debris in wheels. Check that the tracks are free of

lint and threads.

Motor Fails to Run Corrective Measure(s)

On/Off switch turned off

• Turn the machine on by using the switch on the back power pod.

Machine not receiving power • Check that the power connector is securely plugged into the back of

the machine and the three-prong end is plugged into the power source.

Loading...

Loading...