Page 36

Quilt Maker Pro 18 User Manual

201704

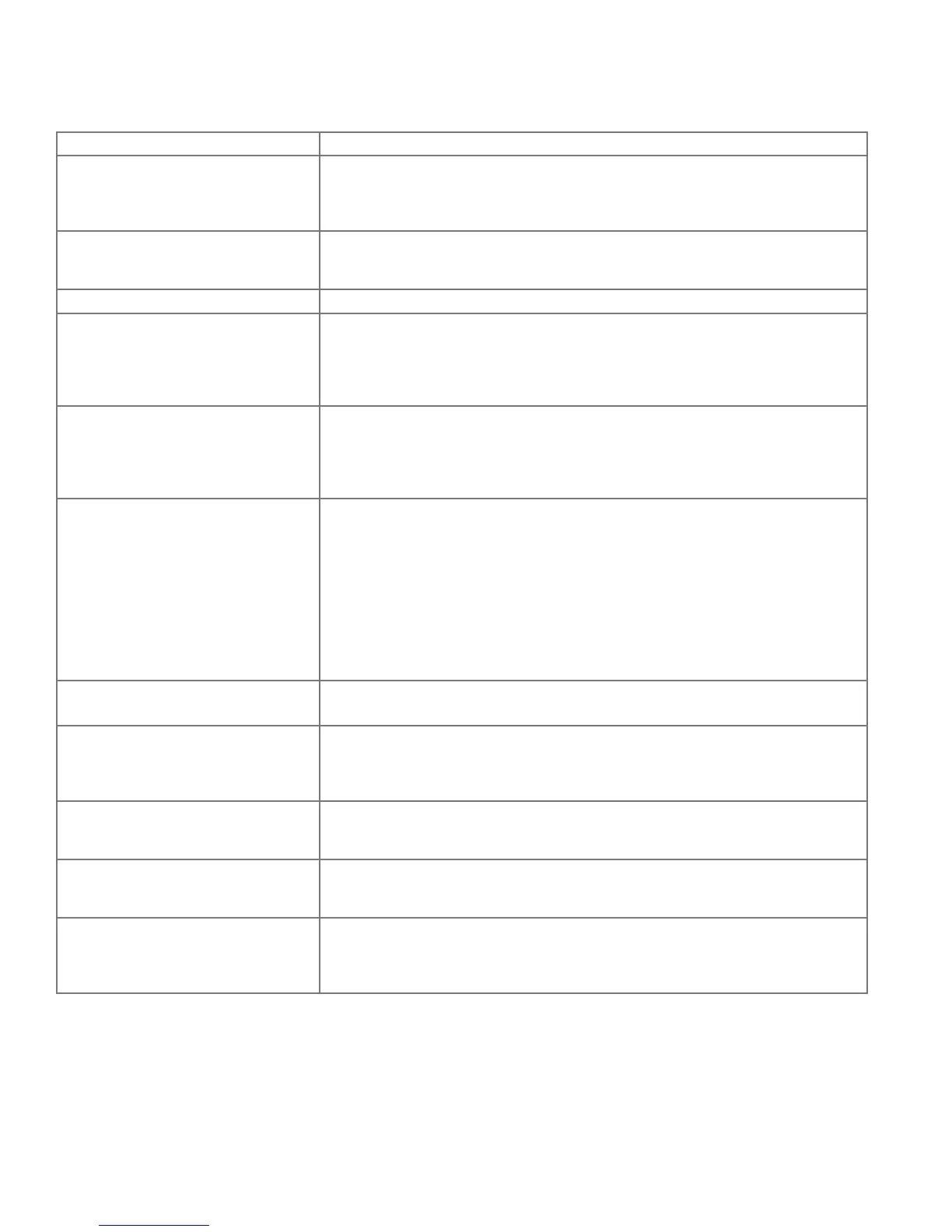

Troubleshooting

Uneven Quilt Design Corrective Measure(s)

Take-up rollers may be bowed

or bent

• Make certain the fabric is not rolled too tight, causing the poles to bow.

Check that poles are inserted completely together with the push pins

engaged so bowing won’t occur.

Leaders are stretched or worn • If fabric is beginning to stretch or fray, contact Janome to purchase

replacement leaders. Do not wash the leaders.

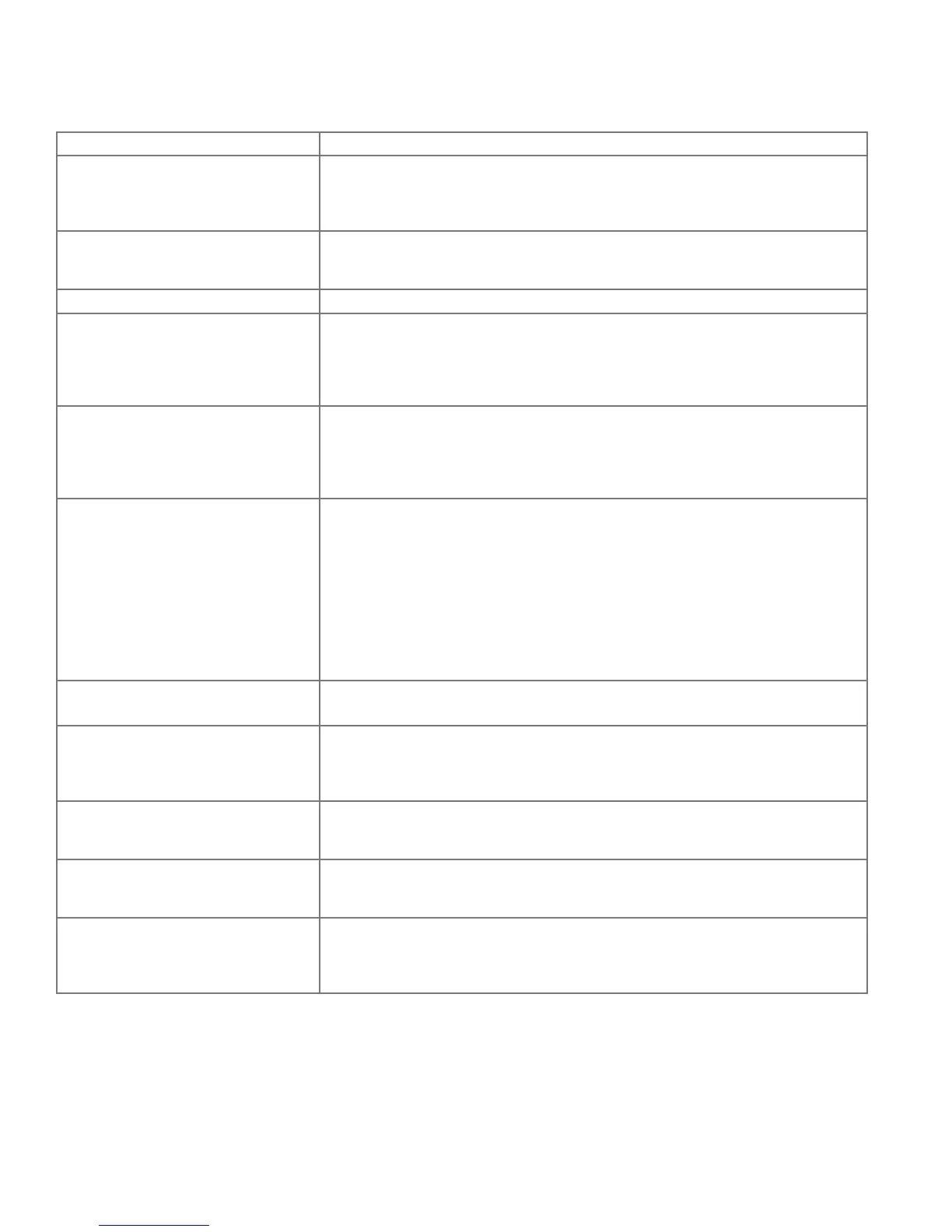

Thread Breaks Corrective Measure(s)

Thread is poor quality or

may have severe twisting or

thread rot

• Look for severe twisting of threads when approximately 12 to 15 inches

has been pulled off, with the ends pinched together. Cotton threads are

particularly susceptible to dry rot or wet rot which makes thread brittle.

Do not use poor quality thread, or thread that is rotted or brittle.

Top and bobbin tensions

not balanced

• Balance the tension of the needle thread after ensuring the bobbin

tension is adjusted correctly. (For more information about adjusting

tension, see Bobbin and Bobbin Tension and Top Thread Tension in the

Using Your Machine section of this manual.)

The machine head has been

threaded incorrectly or thread

spools are not positioned correctly

• Check that the machine is threaded correctly.

• Inspect for accidental double wrapping of thread on thread guides.

• Inspect the thread mast, making sure the eyelets of the mast are

directly over the spools.

• Inspect the vertical positioning of the thread cones. Tipped cones can

dramatically affect thread tension and can cause breakage.

Debris in tension discs

• Inspect for particles and remove any fuzz or debris.

Bobbin rotation is not smooth • Change the bobbin. The slightest hesitation of the bobbin rotation can

be the cause of dramatic tension change and

thread breakage.

Needle is burred, bent or dull, or

installed incorrectly

• Change the needle at least once per quilt. Make sure the needle is

installed to the top of the stop hole in the needle bar.

Needle not suitable for thread • Replace the needle to one better suited for the thread. Use the proper

size needle.

Hesitating too long at one point in

quilting motif

• Move more quickly so stitches don’t overlap or build up. When starting

the machine, begin moving immediately. Sewing in one place too long

will cause the thread to break.

Loading...

Loading...