Page 48

Quilt Maker Pro 18 User Manual

201704

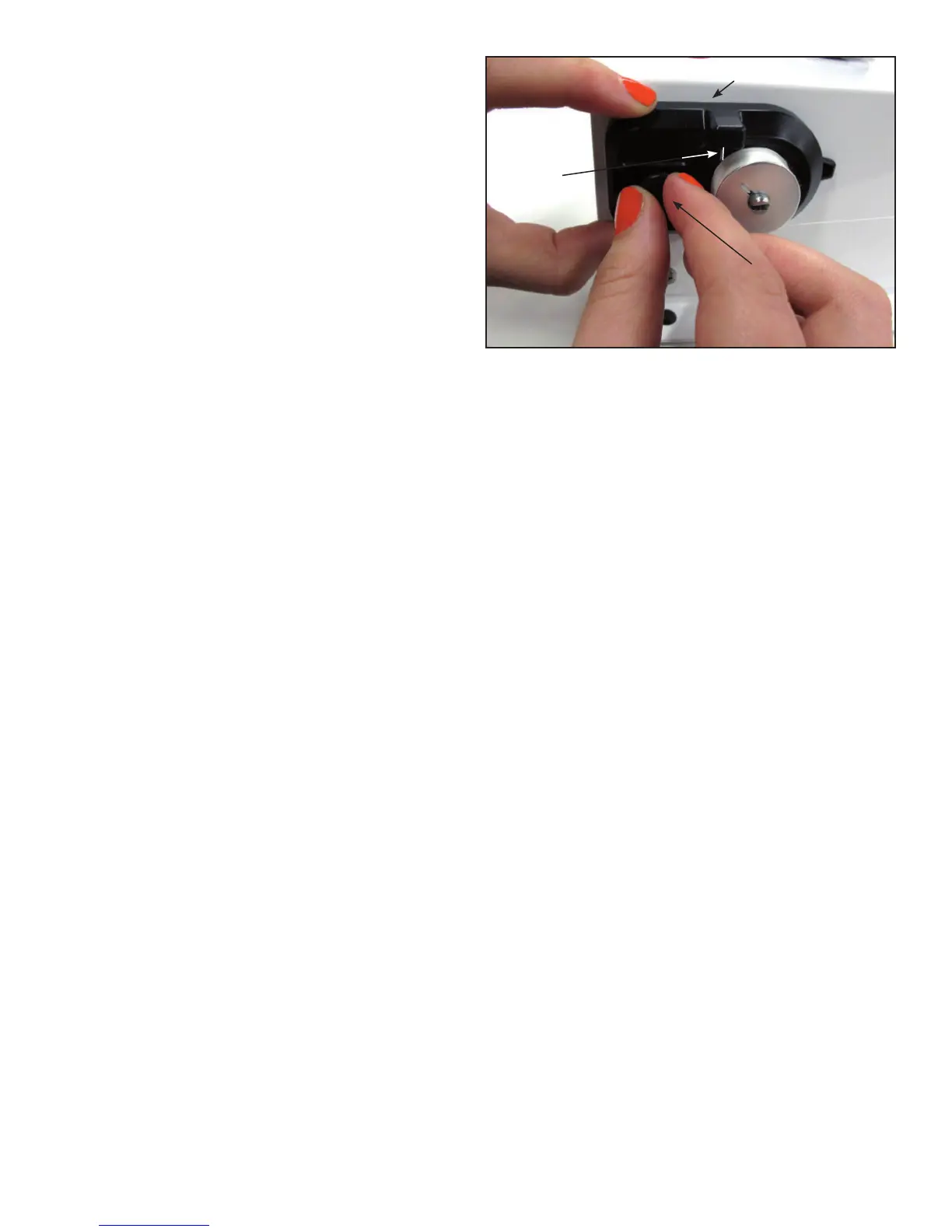

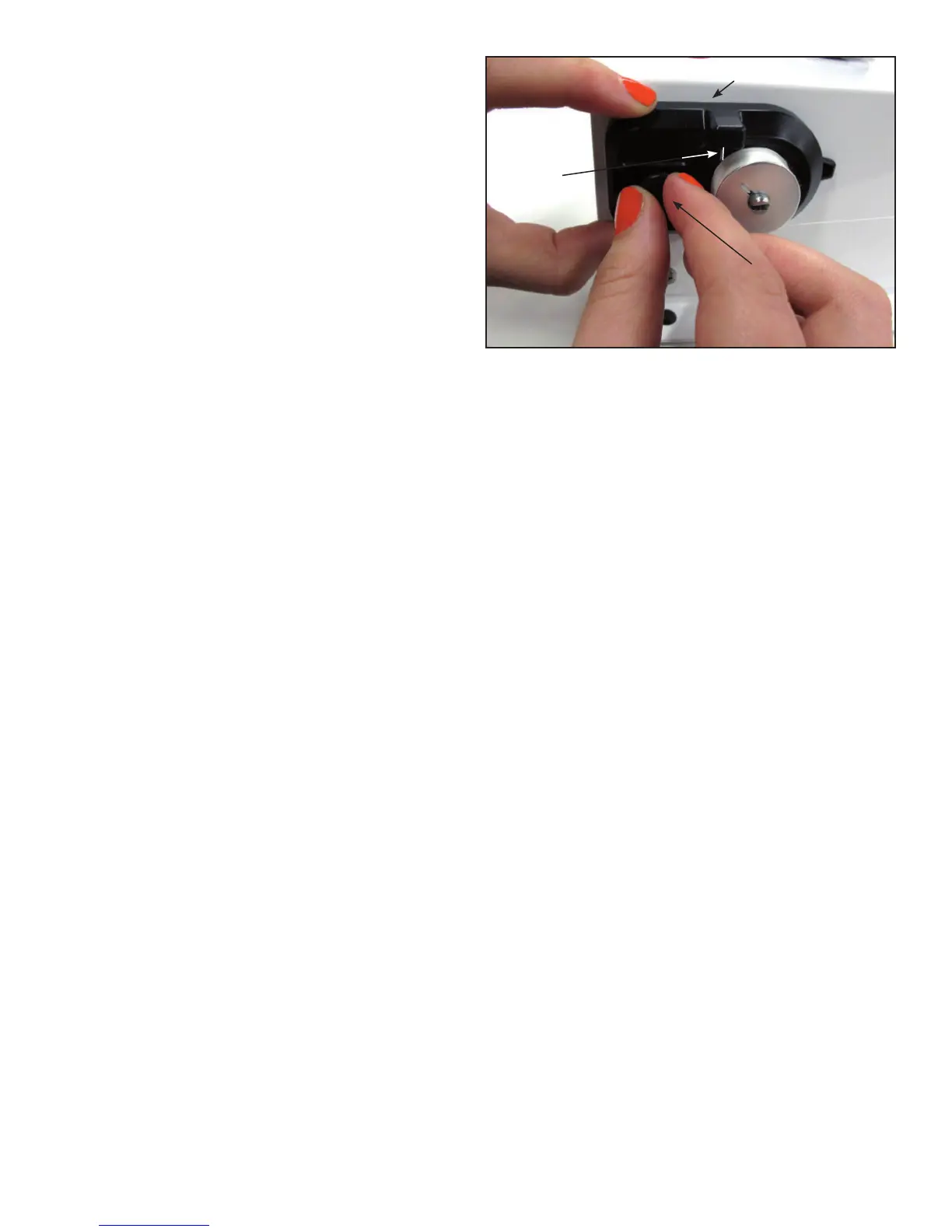

Adjusting the Bobbin Sensor

Assembly

The Stop Sensor is adjusted at the factory for an M-class

bobbin with bobbin weight (fine) thread. If you prefer

more or less thread on your bobbin, the sensor can be

changed with a simple procedure.

1. Fill a sample bobbin with your chosen thread, allowing

the bobbin winder to stop automatically.

2. If the bobbin was wound with too much thread, loosen

the bobbin stop sensor’s adjustment screw enough to

be able to move the sensor assembly (Figure 10).

Move the sensor assembly toward the bobbin, until the

embossed line on the assembly reaches to a position

just before where you want the bobbin to stop filling.

Retighten the adjustment screw.

3. Place an empty bobbin on the bobbin post, thread the

Bobbin Winder and press the start (green) button to

start the winder. When the sensor stops the winder,

press the green button until the bobbin is as full as

you want.

4. Re-adjust the sensor by loosening the adjustment

screw enough to be able to move the sensor assembly.

Move the assembly until the LED indicator turns on,

then move the assembly back slightly and tighten the

screw.

Bobbins will now fill with thread to your chosen

amount of fullness, as long as you are filling the same

size bobbin.

5. You have the flexibility of resetting the sensor for

different bobbins and thread types by following Steps

1-4 above.

Sensor Assembly

Adjustment Screw

Figure 10

Embossed

Line

Loading...

Loading...