AAA-055-00138 Rev. 1/14/15

Jaylor Owner Manual - 66 - Mini Mixer Models

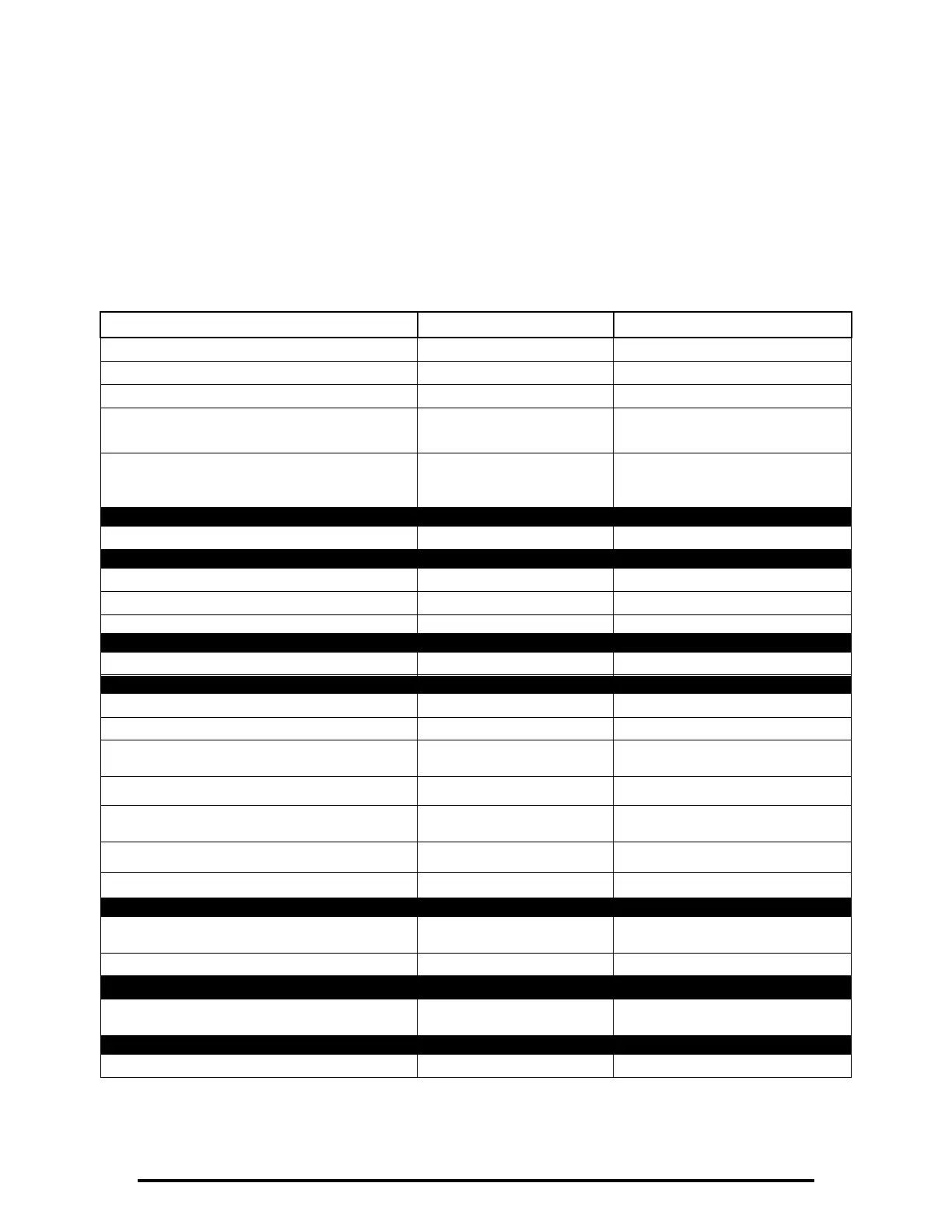

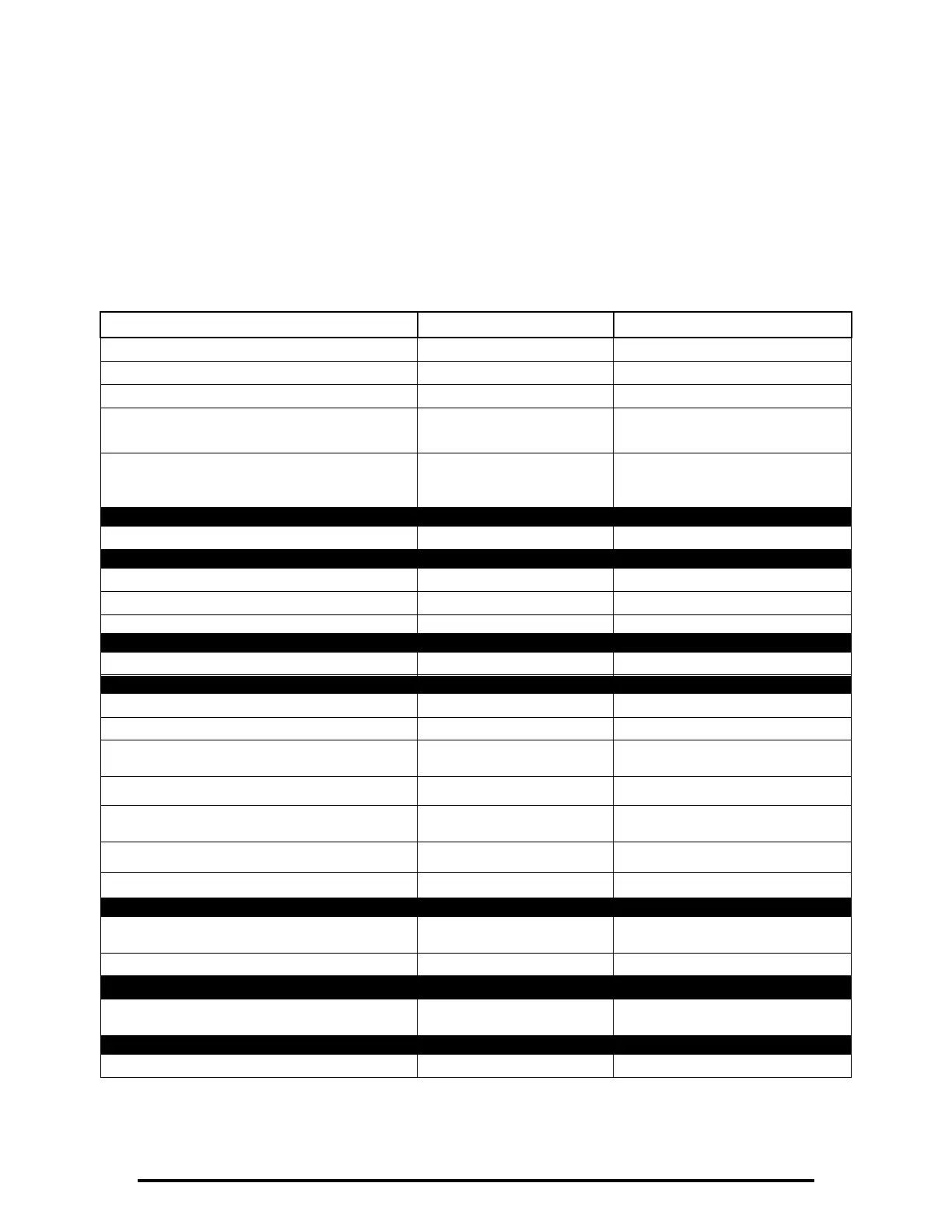

35.0 A50 AND A100 PERIODIC MAINTENANCE CHART

See below a list of common maintenance items and their intervals. Remember, these

maintenance items and intervals are general. Depending on the application, additional

maintenance items may be necessary and/or intervals may be shortened. It is the responsibility of

the operator to properly maintain the equipment based on the specific application.

(Note: Refer to maintenance sections preceding this chart for specific procedures)

Check level in hydraulic oil reservoir All A50/A100’s* Every 1 day

Check that oil cooler fan is operating

Clean area around oil reservoir breather

Check tire pressure

A50/A100 Self-Propelled

and Trailer

Every 1 day

Clean engine cooling intake screen, engine

exhaust shield and area around engine of

A50/A100 Self-Propelled,

Trailer and Truck Mount

Every 1 day

Grease auger support bushing All A50/A100’s Every 10 hours

Check auger knife condition

Check auger leading edge height

Check steering chain tension

Grease steering shaft bearings

Check hardware for tightness

Check parking brake lever tension

A50/A100 Self-Propelled

CE

Every 1 month

Check remote throttle cable play A50/A100 Self-Propelled Every 1 month

Check tire condition

A50/A100 Self-Propelled

and Trailer

Every 1 month

Grease steering gears and u-joint A50/A100 Self-Propelled Every 1 month

Lubricate speed/direction control bushings A50/A100 Self-Propelled Every 1 month

Clean oil reservoir breather All A50’s*

Every 6 months (or immediately

if system develops a leak)

Replace hydraulic oil and filter(s) All A50/A100’s*

Every 1 year (or earlier if oil

quality has degraded)

Engine or electric motor maintenance All A50/A100’s* Refer to manufacturer’s manual

*Does not apply to A50 Skid Steer model

Loading...

Loading...