42 - 6

Drive Head Limited Slip Differential -

Assembly (cont’d)

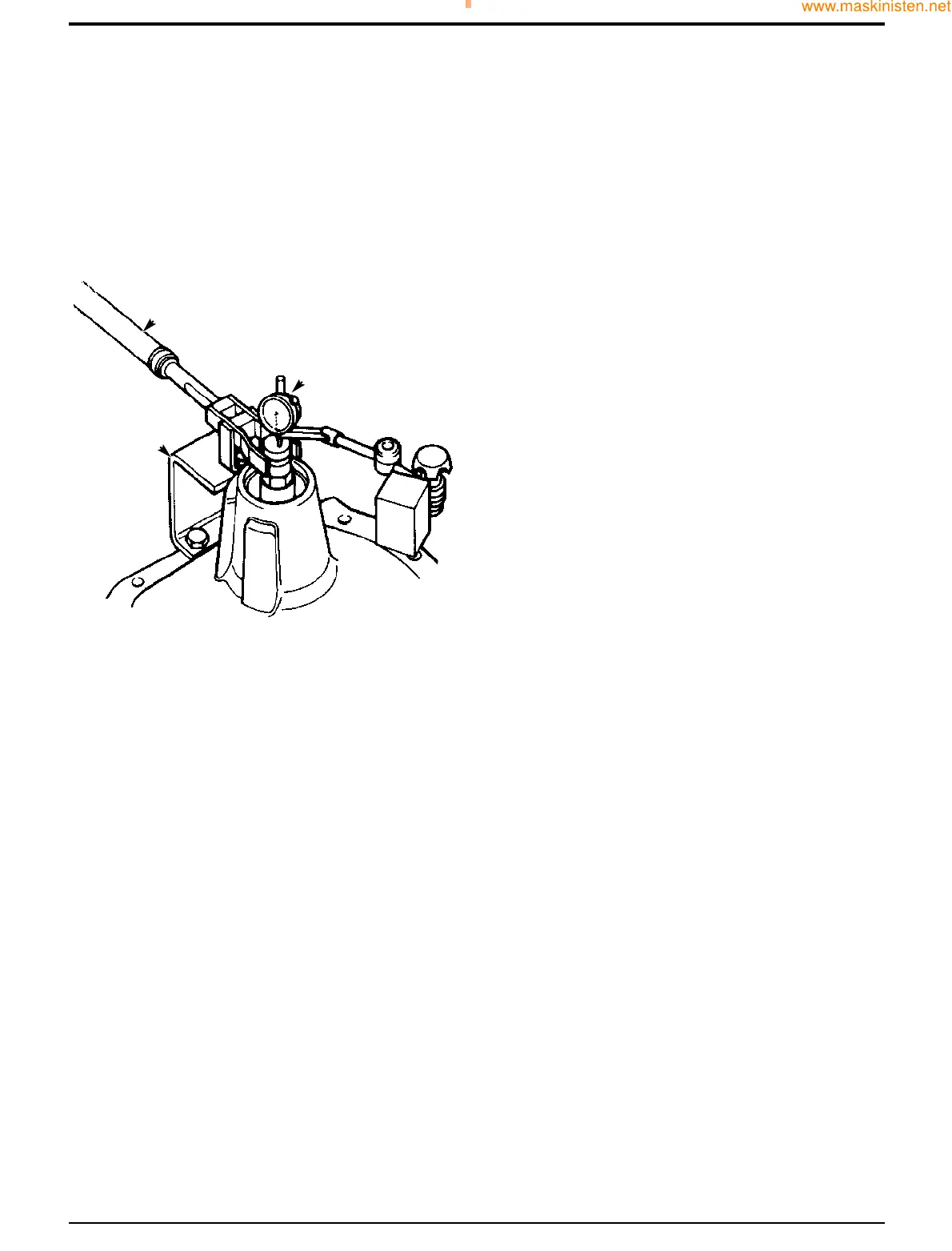

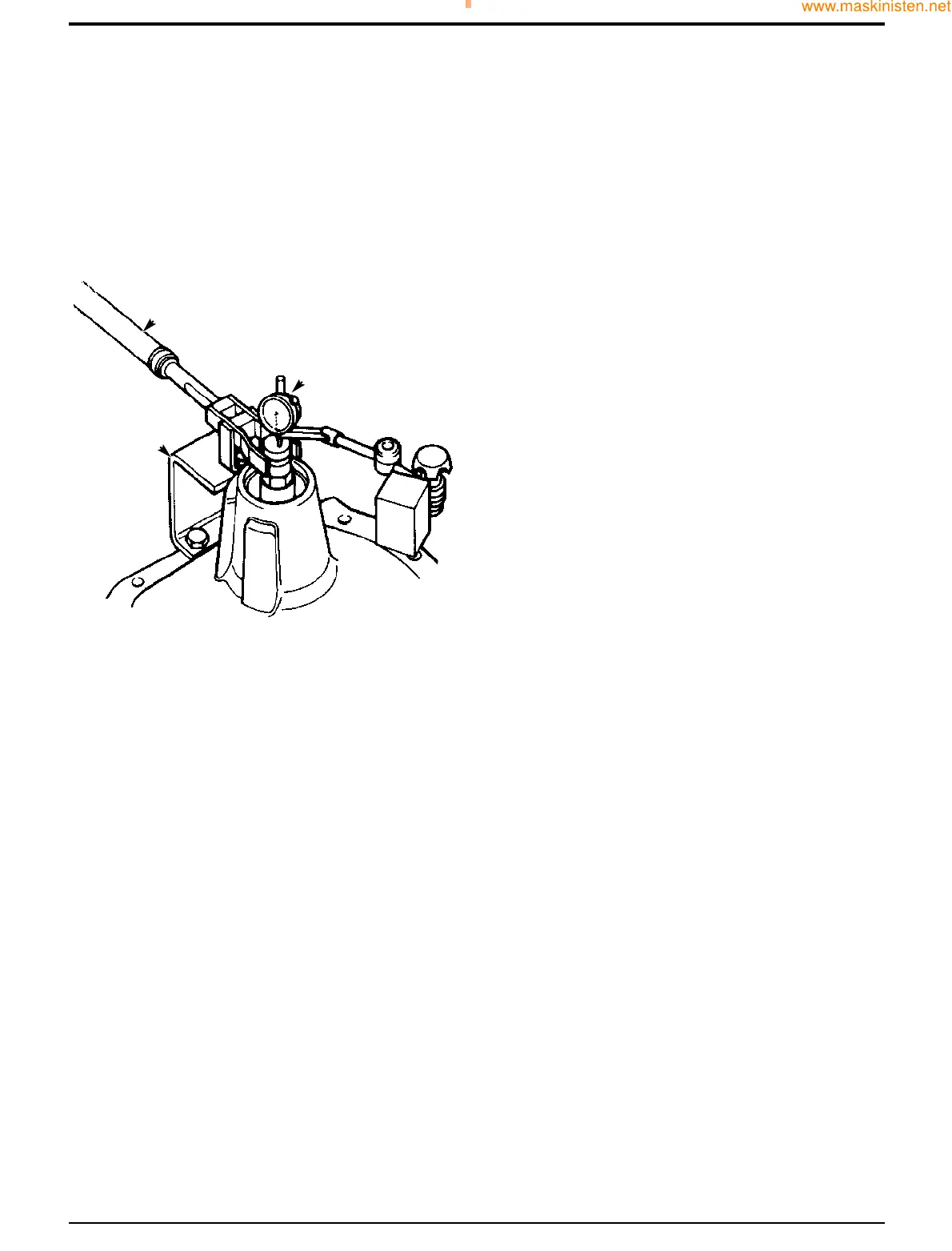

14 Fit dial test indicator (DTI) F. Ensure that the DTI is

mounted on the drive head and not on bracket D.

15 Set torque wrench G to 35 Nm (25.8 lbf ft) and measure

the end float while rotating the shaft.

16 To select the right size spacer 24, subtract the end float

obtained at step 7 from the solid spacer size (14.20

mm). Also subtract 0.04 mm to allow for theoretical

bearing tolerance and pre load. The result is the size of

spacer to be fitted from the solid spacer setting kit. If

there is no spacer of this size, fit the next nearest size

spacer, refer to Service Tools - Axles.

Example

Temporary spacer size 14.20

Subtract end-float 0.25

Total 13.95

Subtract tolerance & preload 0.04

Result 13.91

(No spacer available this size, use next nearest size

spacer i.e 13.900)

17 Remove sleeve B and temporary spacer, fit correct size

spacer from solid spacer setting kit, refer to Service

Tools - Axles. During removal take care to avoid

damaging the outer bearing.

18 Fit sleeve B. Tighten adapter C to no more than 50 Nm

to protect against bearing damage while spacer

selection is verified making sure the pinion is free to

rotate. Check there is no end float and pinion is free to

turn smoothly by hand. Remove adapter C and fit nut

16. Then check that rolling torque is less than 2.0 Nm. If

the rolling torque exceeds 2.0 Nm, check that the shaft

has been assembled correctly.

If the pinion is not free to rotate check the correct size

spacer has been fitted.

19 If rolling torque measured at step 10 is too high, fit the

next larger size spacer. If rolling torque is too low, fit

the next smallest size spacer. If a correct spacer is not

available from the range, check that drive head is

assembled correctly.

20 Remove adapter C and sleeve B. Fit new oil seal 25,

grease between seal lips before fitting. Fit coupling

yoke 22 and NEW stake nut 20.

21 Progressively torque tighten stake nut 20, occasionally

rotating coupling yoke, up to 250 Nm. Providing the

correct size spacer has been selected the rolling torque

should be between 2.3 and 3.4 Nm including seal drag.

Note: The nut tightening torque can be increased to a

maximum of 300 Nm provided that the pinion rolling torque

does not exceed the maximum of 3.4 Nm.

22 Finally stake the nut 20 into the slot.

23 Fit bearing caps 2A using bolts 2B tightened to 165 Nm

(121 lbf ft). Make sure the manufacturer's marks are

correctly aligned.

Note: Drivehead casing 2 and bearing caps 2A are

matched and should be renewed as a complete assembly

if damaged or worn.

24 Locate differential assembly (without bearings) into

drivehead.

Section F Transmission

9803/7130

Section F

42 - 6

Issue 1

Front Axle

FF

GG

348040

DD

Loading...

Loading...