61 - 7

Assembly (Cont'd)

46 Using a bearing puller, remove the layshaft bearing cup

from the rear casing. Referring to the shim thickness

calculation for the layshaft 52, fit the required shims

into the rear casing. Using a bearing dolly, refit the

layshaft bearing cup.

47 Repeat step 46 for the main shaft 53, output shaft 41

and reverser unit 54.

48 Turn the rear casing over.

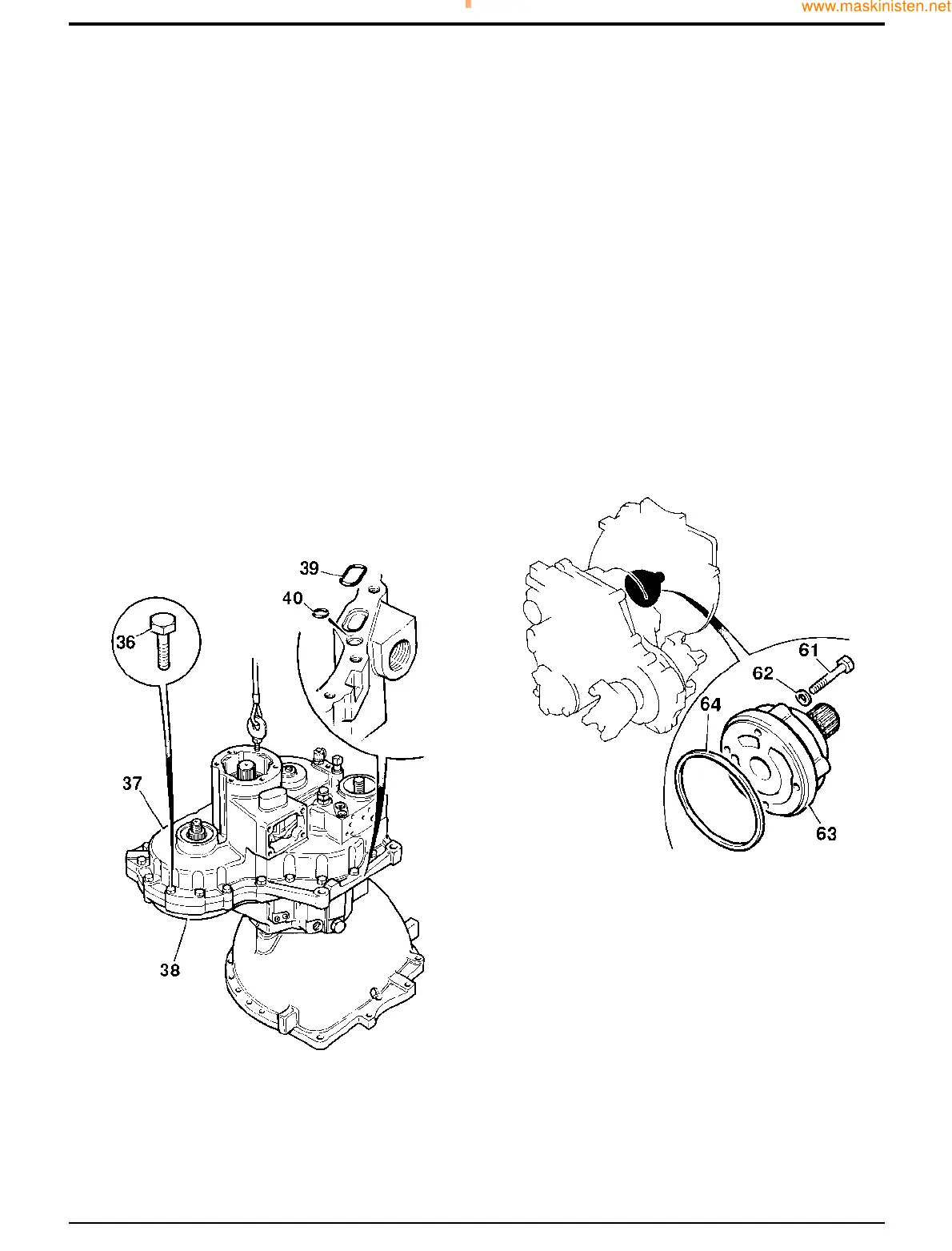

49 Fit the face 'O' rings 39 and 40 into the front case

mating face recesses.

50 Apply a bead of sealant to the front case mating face,

smoothing the sealant around the 'O' ring areas.

51 Screw a lifting eye into the layshaft end cover bolt hole

of the rear casing 37. Using a suitable hoist, lift the rear

casing into position over the front casing 38. Carefully

lower the rear case onto the front case, ensuring that

the locating pegs are fully engaged. Secure the casings

with bolts 36. Torque tighten to 56 Nm (41.3 lbf ft).

Remove the lifting eye.

52 Repeat end float measurements, as detailed in steps 15

to 36 inclusive, to check that end float on all shafts

remains within the tolerance of 0.03 to 0.08 mm.

53 If any measurement is outside the tolerance, remove

rear casing, see step 45. Using a bearing puller, remove

the bearing cap(s) of the shaft(s) that is outside the

tolerance. Add or remove shim(s) to bring the

measurement(s) within the tolerance. Using a bearing

dolly, refit the bearing cup(s) into the rear casing.

54 Remove the front case 'O' rings 39 and 40 and clean

the sealant from the front case mating face.

55 Repeat steps 49 to 52 inclusive. The end float

measurements should now be within the tolerance for

all shafts. If any measurement is still outside the

tolerance, repeat step 53.

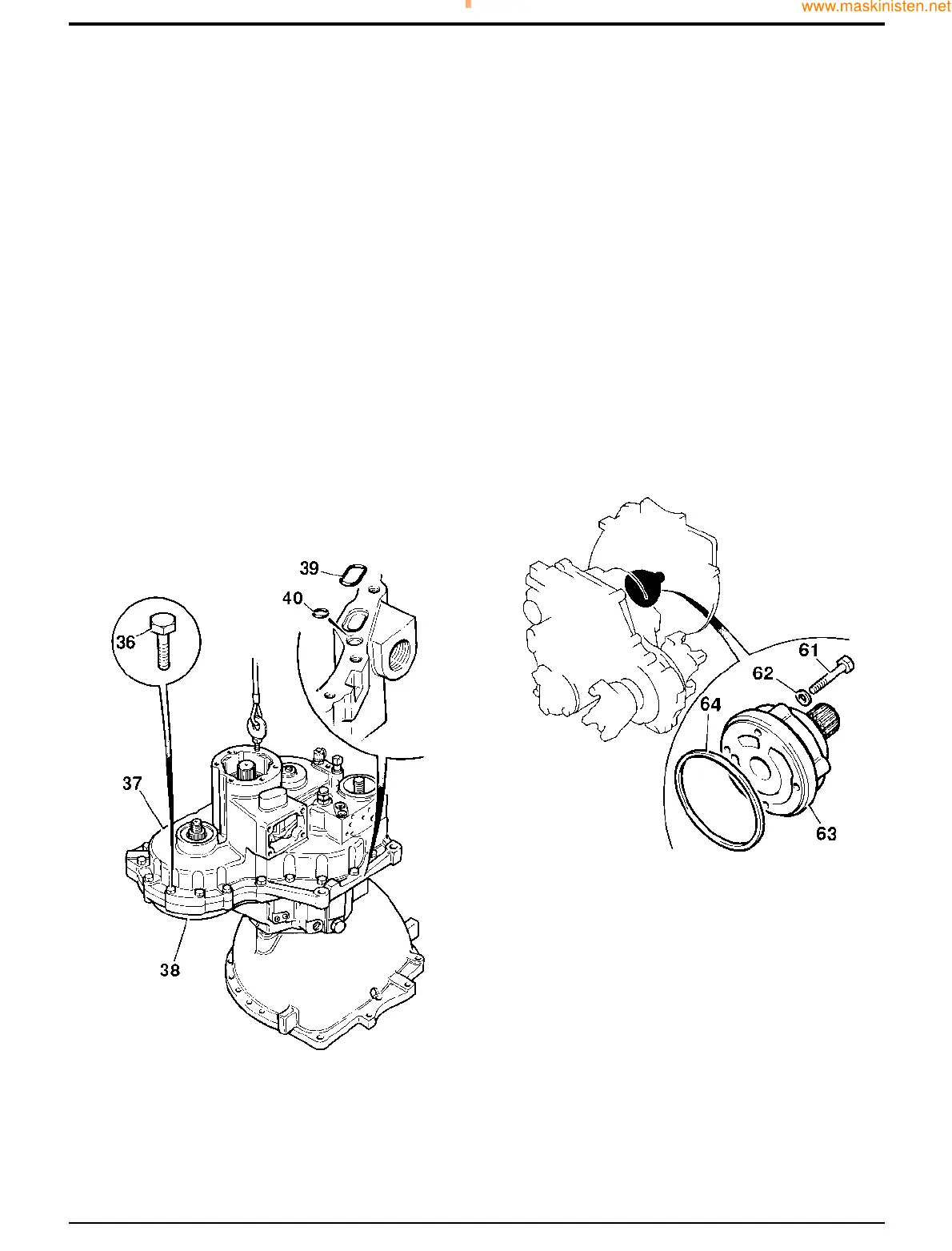

56 Turn the gearbox into the horizontal position. Fit new

'O' ring 64 to the oil pump assembly. Refit the oil pump

assembly and secure with new washers 62 and bolts

61. Torque tighten to 28 Nm (20.7 lbf ft). Make sure that

the pump rotors rotate.

57 Pack the cavity between the lips of both front and rear

output shaft oil seals 17 with grease and fit the seals.

58 Fit the rear output yoke 15 and front output brake disc

15A and secure with attachment bolts 13. Do not fully

tighten. Align the front and rear output yokes.

59 Fit the gear change turret 19 with a new gasket 20 and

secure with setscrews 18. Torque tighten to 56 Nm

(41.3 lbf ft).

60 Fit oil inlet adaptor 65 with new sealing washer 66 into

the rear casing. Torque tighten to 102 Nm (75.2 lbf ft).

61 Fit taper plug 67. Torque tighten to 56 Nm (41.3 lbf ft).

Section F Transmission

9803/7130

Section F

61 - 7

Issue 1

Syncro Shuttle Gearbox

S203980

S203991

Loading...

Loading...