5 - 9

Routine Maintenance (continued)

Compressor Oil and Filter - Drying the Separator

Element

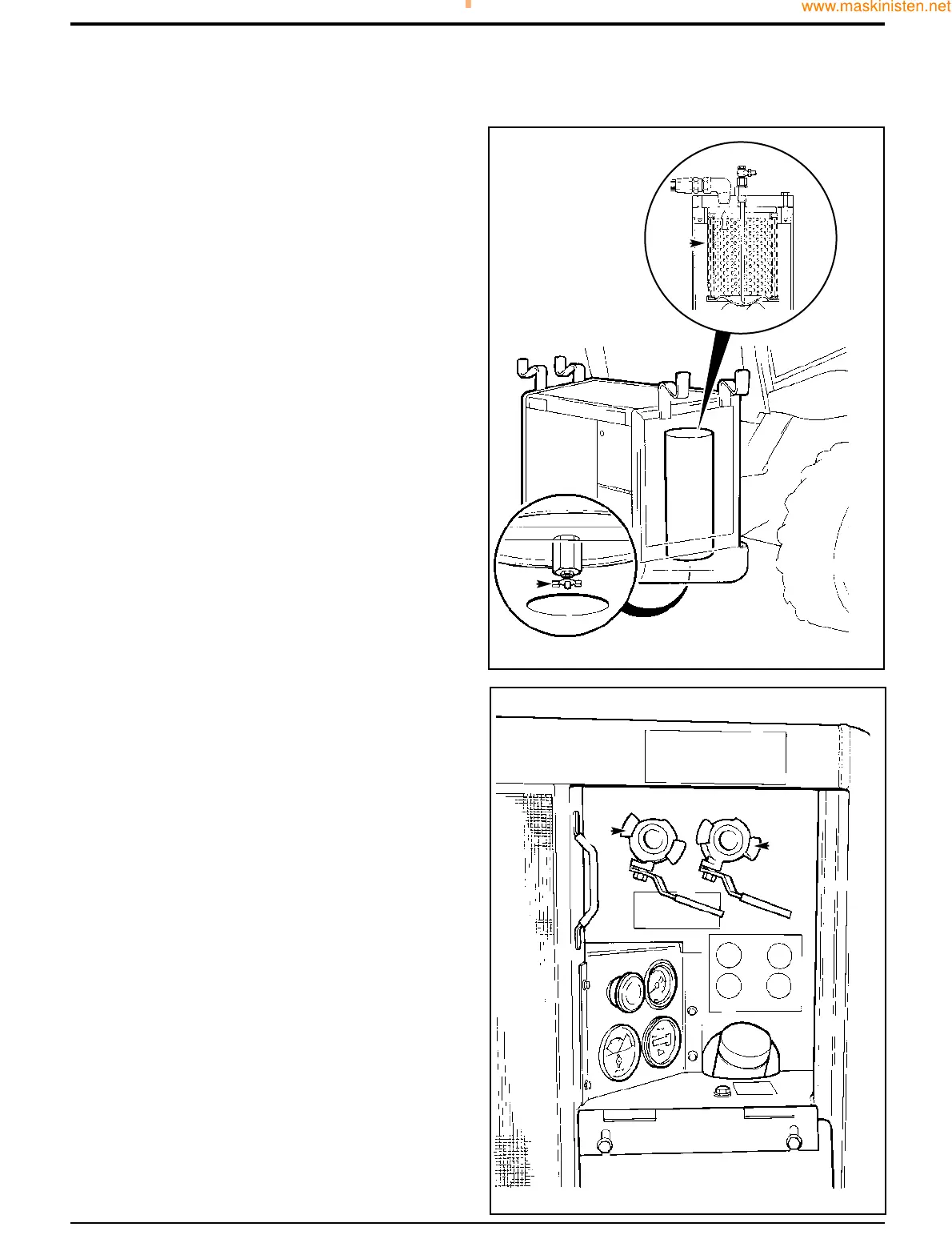

The air/oil receiver separates the oil from the air/oil mixture

after compression has taken place.

In extreme conditions it is possible for the separator element

(A) to become saturated. This condition could result in oil

carry over (oil through tool air lines).

The procedure below describes how to dry out the separator

element.

1 Park the machine on firm level ground. Engage the

parking brake and set the transmission to neutral.

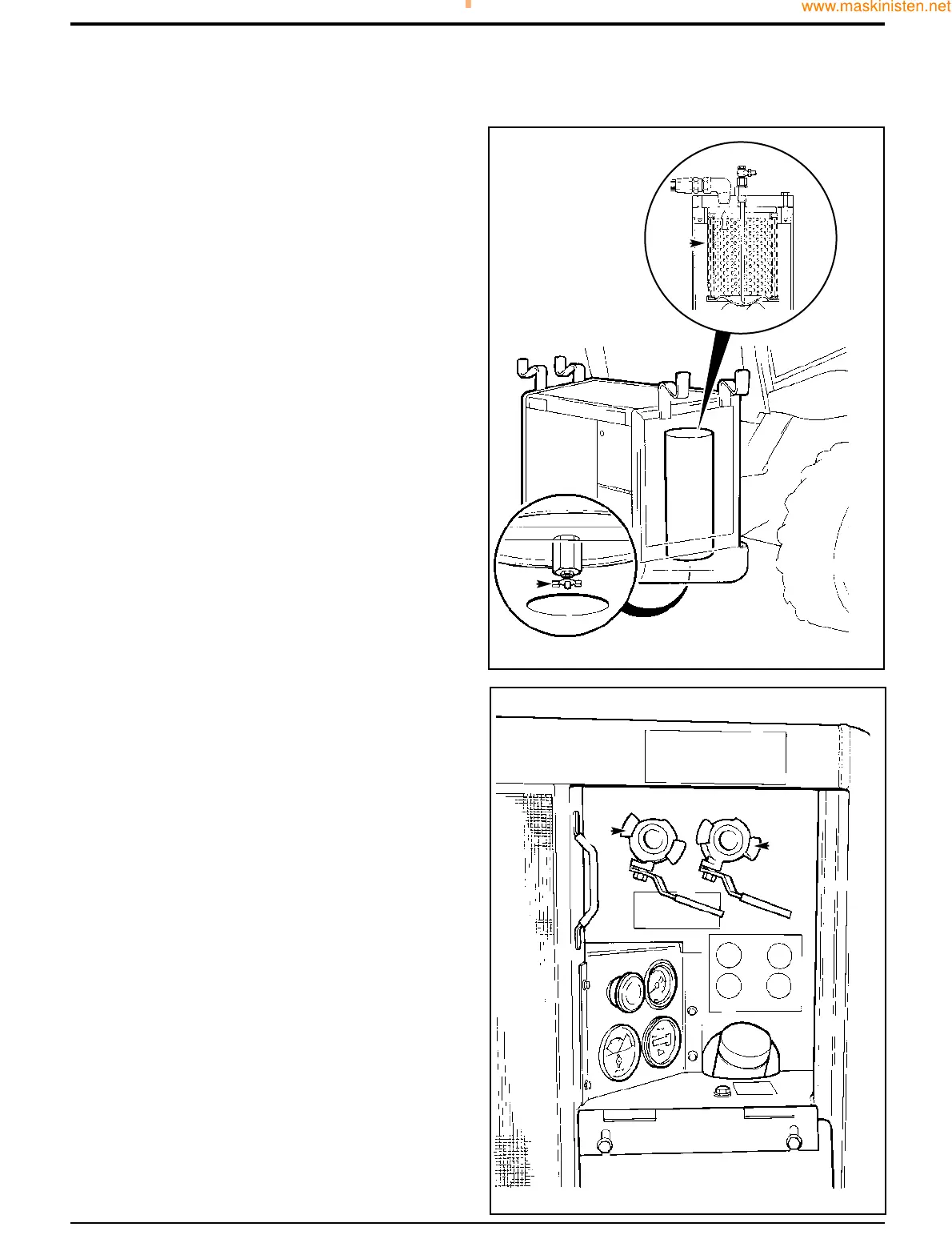

2 Run the compressor at maximum revs for 10 minutes

with the air cocks B closed.

!!

CAUTION

Stand clear and to one side when opening the air cock.

Never allow compressed air to be directed to your skin.

Compressed air can cause injury to you or others.

3 Open one air cock slightly without any pressure drop

on the gauges, run the compressor at maximum revs

for a further 10 minutes.

Note: The above procedures should dry out the separator

element and stop oil carry over, however further checks are:

i Check the oil level, make sure that the correct grade of

oil has been used.

ii Drain the separator tank daily (tap C).

iii Make sure the machine does not work on a steep

incline (up to 15% allowed) for an extended length of

time.

Section A Attachments

9803/7130

Section A

5 - 9

Issue 1

Airmaster Compressor

S250790

S211960

S211910

BB

BB

AA

CC

Loading...

Loading...